Automatic Welding System

PORTABLE COLUMN AND BOOM WELDING MANIPULATOR

POPWELD portable welding manipulator MNP-600 is used in applications of automated welding, where precision and efficiency are nepocessary. It provides weld boom stiffness, welding head stability, operator controls, and ease of use as key driving factors

AUTOMATED GTAW (TIG) LONG & GIRTH SEAM WELDING MANIPULATOR

INTRODUCTION

Introducing popweld’s Automated GTAW (TIG) Long & Girth Seam Welding Manipulator powered by EWM Tetrix 552 AC/DC with cooling unit. This unit uses a range of cutting edge technologies allowing operators to take full control over weld parameters and work with difficult materials.

COLUMN & BOOM MANIPULATOR

Column & Boom Manipulator allow maximum flexibility to welding head manipulation which results in a higher quality of welds. Another benefit is the low skill cap for operators due to automated processes. Generally, our welding manipulators are indispensable for applications that involve pipes and vessels.

CLADDING, OVERLAY & BUILD UP SYSTEM

Super Duty Cladding, Build Up & Overlay Side-Beam/Gantry Manipulator

Welding Automation is introducing a new Super Duty Cladding, Build Up & Overlay Side-Beam/Gantry Manipulator. Besides being compatible with a variety of industry leading power sources, this unit is also capable of integrating turning rolls or positioners and can be customized to customer requirements.

High-Capacity Mid-Range Chain Lift Welding Manipulator

A pipe spool fabrication facility needed to alleviate the bottleneck of time consuming pipe/flange/elbow fit-up with a range of 2" through 60" diameter. Fit-up cycle times were taking several hours on average and required a welder/fitter and one helper. In addition, the customer needed height adjustable welding positioner with torque output suitable to handle the very large offset loads required.

Welding Systems and Heavy-Duty Equipment Can Help You Today

popweld isolated the main concerns, and solved each one. The new system would look like this (2 production cells on same track system):

Automated Welding Systems

popwelding was recently tasked with building a pipe welding system to improve throughput, quality and safety. As a global provider of efficient and integrated boiler room solutions for applications of any size, approached with the requirements to build a system that would reduce costs, increase safety, and improve quality in their operations.

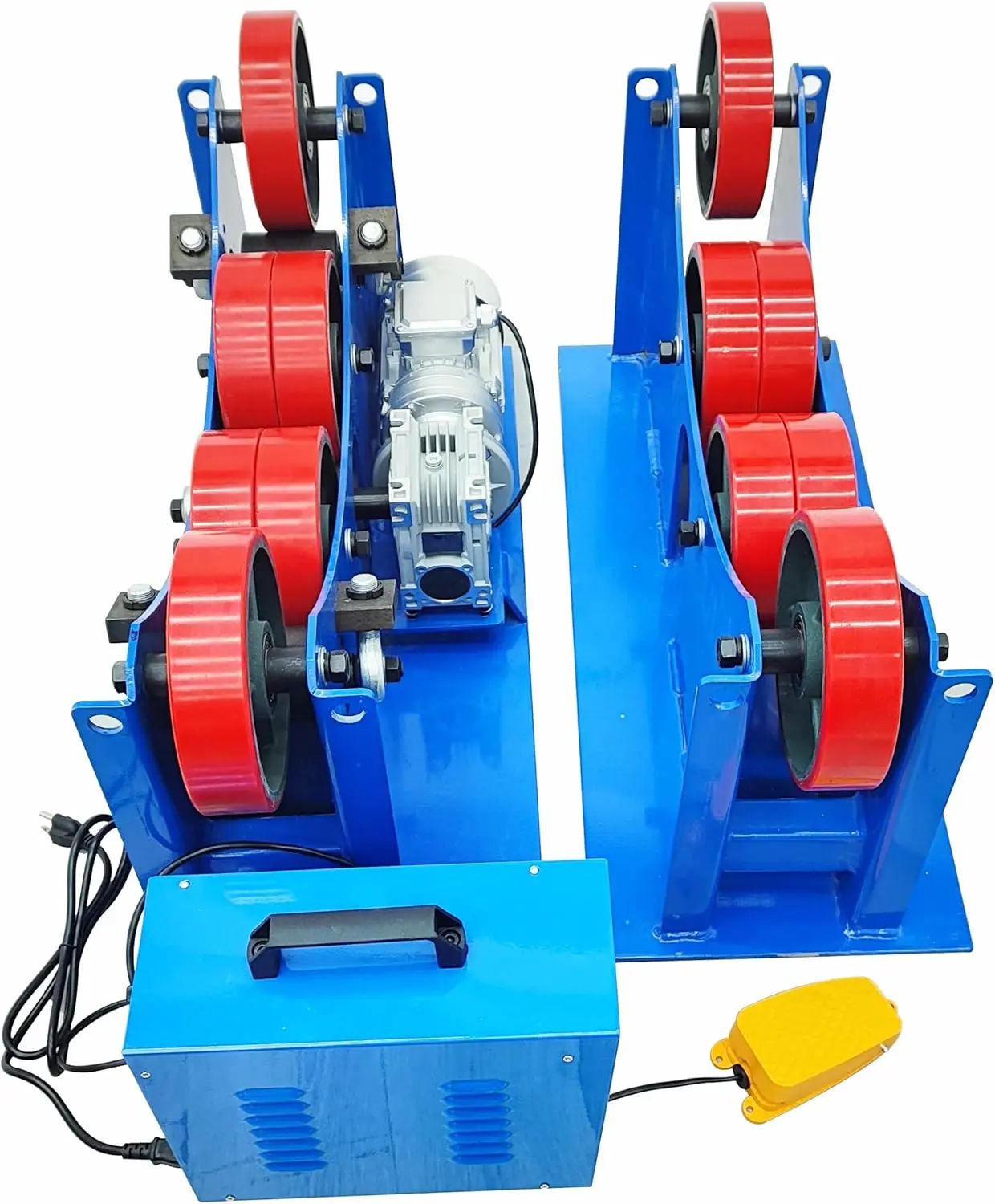

Weld Plus Pipe Welding Station

This Weld Plus Pipe Welding Station is a turn-key solution for pipe welding! The positioner is designed to rotate pipe while the torch stand holds a mig gun over the workpiece. In addition, a POPWELD weld oscillator manipulates the mig gun to assist with fill passes on the pipe. The POPWELD Pipeworx 400 is designed exclusively for pipe fabrication. Furthermore, A POPWELD ROI allows the operator to adjust weld parameters from a safe distance. In conclusion, this Pipe Welding Station is a must-have for any pipe fabricator!