The demand for Saw Welding Machines has seen a significant rise in various industries, driven by the need for enhanced efficiency and precision in metal fabrication. According to a recent market research report, the global welding equipment market is projected to reach $29.33 billion by 2025, with a notable portion attributed to advancements in welding technologies, including saw welding. This growth is fueled by the increasing utilization of automated welding processes in manufacturing, construction, and shipbuilding sectors, where the benefits of accuracy and speed are paramount.

Choosing the right Saw Welding Machine can be a daunting task, considering the diverse range of options available today. As industries strive for higher production standards, it becomes essential to understand the various features, capabilities, and applications of these machines. With factors such as material compatibility, efficiency ratings, and user-friendliness to consider, making an informed decision is crucial. By evaluating specific operational requirements and future project goals, businesses can ensure that their investment in a saw welding machine aligns perfectly with their long-term manufacturing objectives.

Saw welding machines are essential tools in various industrial applications, offering a robust solution for metal joining processes. Understanding the types of saw welding machines and their specific applications is crucial for selecting the right equipment for your needs. Generally, saw welding machines can be categorized into two primary types: automatic and manual. Automatic saw welding machines are designed for high-volume production environments, where precision and efficiency are paramount. According to a recent industry report, the global demand for automatic welding machines is expected to grow by 5.7% annually through 2025 due to advancements in automation technologies.

Manual saw welding machines, on the other hand, are favored for their versatility and ease of use in smaller workshops or for specialized tasks. These machines allow operators to have greater control over the welding process, making them ideal for custom projects or low-volume production. Data indicates that manual machines hold a significant market share, particularly in craft and repair applications, where the flexibility to adapt to varying workpieces is critical. As industries continue to evolve, understanding the specific capabilities and applications of each type of machine will help businesses make informed decisions, ensuring efficient operations and high-quality outcomes in their welding tasks.

| Type of Saw Welding Machine | Power Source | Applications | Advantages | Considerations |

|---|---|---|---|---|

| Manual Saw Welding Machines | Electric | Small-scale projects, Repairs | Cost-effective, Portability | Requires operator skill, Limited to basic tasks |

| Automatic Saw Welding Machines | Pneumatic/Electric | Mass production, Assembly lines | High efficiency, Consistent quality | Higher initial investment, Requires maintenance |

| Portable Saw Welding Machines | Battery/Electric | Fieldwork, On-site repairs | Mobility, Ease of use | Limited power, Short battery life |

| CNC Saw Welding Machines | Electric | Custom fabrication, Complex designs | Precision, Automation | High cost, Requires programming knowledge |

When selecting a saw welding machine, understanding key technical specifications is crucial for optimal performance. One of the primary factors to consider is the welding power output. A machine's amperage capacity affects the thickness of the materials it can work with, so choosing a model with appropriate power output tailored to your specific projects is essential. Additionally, look for machines that offer adjustable power settings, allowing for versatility across different tasks and material types.

Another important specification is the duty cycle, which defines the time a machine can operate before it needs to cool down. For heavy-duty applications, a higher duty cycle ensures consistent performance without overheating, making it a critical factor for professionals tackling extensive welding jobs. Moreover, the design and ease of use, including portability and ergonomic features, can significantly enhance user experience and efficiency, especially in environments requiring frequent relocation of equipment. By carefully evaluating these technical specifications, you can select a saw welding machine that best meets your operational needs.

When it comes to choosing the best saw welding machine for your needs, a comparative analysis of leading brands in saw welding technology is essential. Recent industry reports highlight that the global market for saw welding machines is expected to grow at a CAGR of 7.5% through 2025, underscoring the increasing importance of efficiency and precision in manufacturing processes. Key factors driving this growth include advancements in technology and the rising demand for high-quality welded joints in various applications.

In the context of this growth, three distinguishing features emerge among top competing brands: automation capabilities, ease of use, and service support. Machines that incorporate advanced automation can significantly reduce human error and improve overall productivity, while user-friendly interfaces make training new operators quicker and simpler. Furthermore, reliable service support is crucial; according to a recent survey, 65% of manufacturers rated prompt service as a vital factor in their purchase decisions.

Tip: When evaluating saw welding machines, assess the level of automation offered. Look for models with programmable features that align with your specific welding tasks to enhance productivity and consistency.

Additionally, consider the machine's energy consumption and durability, as these factors can greatly influence long-term operational costs. Reports indicate that energy-efficient machines can reduce power consumption by up to 30%, making them an attractive choice for manufacturers looking to enhance sustainability without compromising on output quality.

Tip: Always check for comprehensive warranty options and the availability of replacement parts, ensuring that your investment remains protected and functional over time.

When considering the purchase of a saw welding machine, a critical aspect to evaluate is the cost-benefit ratio of investing in quality equipment. According to a report by the International Institute of Welding, well-maintained welding machines can offer productivity gains of up to 30%. This increase in efficiency not only reduces project timelines but also maximizes the overall output, making a compelling case for investing in higher-quality machines.

Moreover, the durability and reliability of reputable welding equipment can significantly lower long-term maintenance costs. A survey conducted by the Fabricators & Manufacturers Association indicated that companies using quality welding machines reported 20% fewer downtime incidents compared to those with lower-priced models. This data underscores the idea that an upfront investment, although potentially higher, can yield substantial savings over time by decreasing the frequency and cost of repairs and ensuring that operations run smoothly. Buyers should prioritize equipment that provides these long-term benefits, as they contribute to a more favorable return on investment.

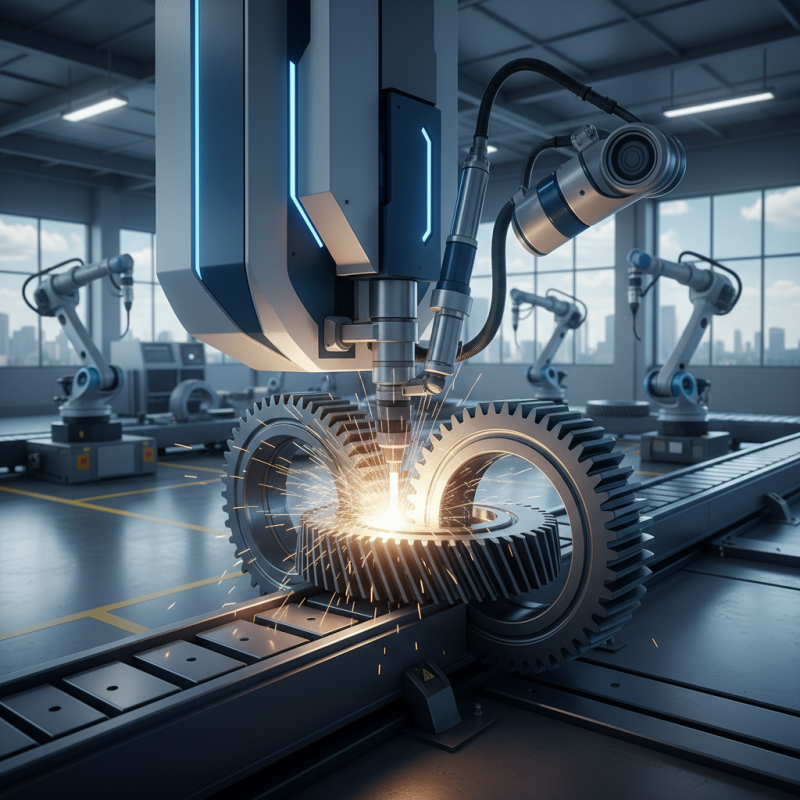

As we move towards 2025, the landscape of saw welding machinery is set to undergo significant transformation fueled by technological advancements. One of the most prominent innovations on the horizon is the integration of artificial intelligence (AI) into welding machines. This technology will not only enhance precision but also streamline the operational process, allowing for real-time adjustments based on real-world variables. Such intelligent systems will dramatically reduce wastage and improve overall efficiency in production environments.

Another noteworthy trend is the shift towards automated and robotic welding solutions. These automated systems are designed to handle complex welding tasks with minimal human intervention, thus improving safety and consistency. As industries seek to reduce labor costs and increase output, the adoption of collaborative robots—often referred to as cobots—will become more prevalent. These smart machines, equipped with advanced sensors and machine learning capabilities, will work alongside human operators, enhancing productivity while ensuring high-quality results.

Moreover, the rise of eco-friendly technologies in the welding sector cannot be overlooked. The demand for sustainable practices is prompting manufacturers to develop saw welding machines that consume less energy and emit fewer pollutants. Innovations such as laser welding techniques and hybrid machinery are paving the way for a greener future. As sustainability continues to be a key consideration, companies that embrace environmentally friendly solutions will not only meet regulatory standards but also appeal to a growing base of environmentally conscious consumers.