As the welding industry continues to evolve, efficiency and precision remain at the forefront of advancements in welding techniques and equipment.

The Swing Welding Dolly is a pivotal tool designed to enhance the performance and accuracy of welding projects.

According to a recent market analysis by the Welding Equipment Manufacturers Association, the global market for welding tools is projected to reach $20 billion by 2025, highlighting the increasing importance of innovative solutions such as the Swing Welding Dolly in optimizing productivity.

The Swing Welding Dolly is a pivotal tool designed to enhance the performance and accuracy of welding projects.

According to a recent market analysis by the Welding Equipment Manufacturers Association, the global market for welding tools is projected to reach $20 billion by 2025, highlighting the increasing importance of innovative solutions such as the Swing Welding Dolly in optimizing productivity.

The Swing Welding Dolly serves as an essential component for welders, providing stability and adaptability when working on various surfaces.

With its ergonomic design and ability to accommodate different welding positions, it significantly reduces the physical strain on operators, allowing for extended periods of high-quality work.

In fact, industry reports suggest that utilizing specialized tools like the Swing Welding Dolly can enhance welding efficiency by up to 30%, making it an indispensable asset for professionals aiming for superior results in their projects.

As we delve into the ultimate guide for using the Swing Welding Dolly effectively, it is crucial to understand not only its operational benefits but also how its innovative design aligns with the broader trends in the welding industry.

By embracing such advanced tools, welders can ensure they remain competitive in a rapidly changing landscape, enhancing their craftsmanship and project outcomes.

The Swing Welding Dolly has emerged as an indispensable tool in the welding industry, largely due to its unique design that enhances maneuverability and precision. According to a report by the American Welding Society, the use of specialized welding equipment like the Swing Welding Dolly can improve productivity by 30% in complex projects. This is primarily attributed to its ability to provide stable support and orientation, allowing welders to focus on achieving high-quality welds without the usual physical strain.

Key features of the Swing Welding Dolly include its adjustable height and robust structural design, which facilitate various welding positions and angles. A study by the Welding Equipment Manufacturers of America indicates that optimized equipment tailored for specific tasks can significantly reduce operator fatigue and increase efficiency. Furthermore, the dolly's lightweight yet sturdy framework not only enhances portability but also ensures longevity, making it a valuable investment for both professional and hobbyist welders.

As such, incorporating the Swing Welding Dolly into one's toolkit can lead to marked improvements in both performance and safety on the welding site.

When utilizing a Swing Welding Dolly, prioritizing safety measures is crucial to ensure maximum efficiency in your welding projects. Firstly, always wear appropriate personal protective equipment (PPE) such as welding helmets, gloves, and flame-resistant clothing to shield yourself from sparks and intense heat. Maintaining a clean work environment is equally important; remove any flammable materials from the vicinity to prevent potential hazards from arising during the welding process. Furthermore, ensure that the dolly is designed for the specific weight and size of the workpiece to maintain stability and avoid accidents.

In addition to personal safety, it's essential to regularly inspect the Swing Welding Dolly for any signs of wear or damage. Check for loose wheels, structural integrity, and ensure that all components are functioning correctly. Proper maintenance not only prolongs the lifespan of the equipment but also enhances overall performance. By recognizing the importance of safety and maintenance when using the Swing Welding Dolly, welders can achieve more precise results while minimizing risks associated with welding operations.

In the welding industry, utilizing the right tools is crucial for achieving optimal results. The swing welding dolly is designed to enhance efficiency and accuracy in welding tasks, yet understanding the top industry standards for its performance is essential for users seeking to maximize its potential. These standards often incorporate factors such as weight distribution, balance, and maneuverability, which all contribute to a welder's ability to perform intricate tasks with precision.

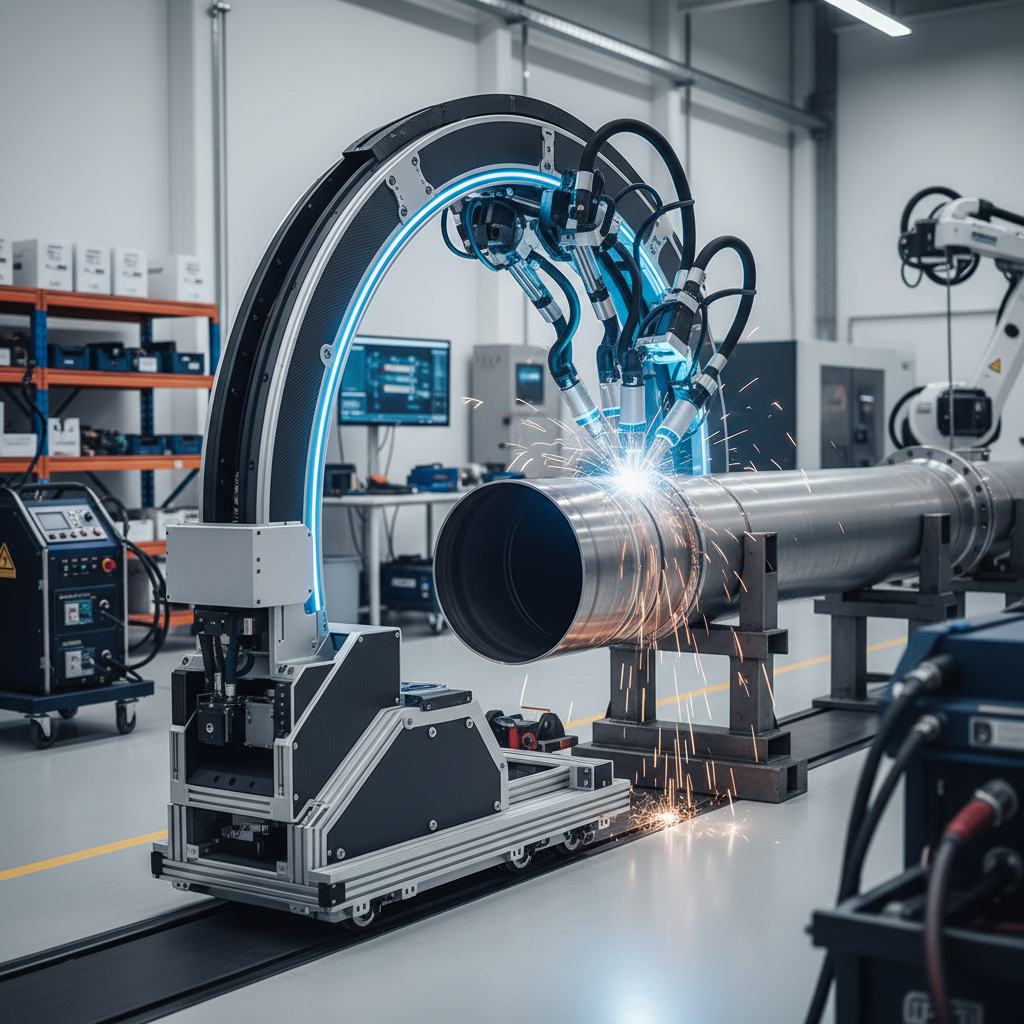

Moreover, like many other sectors, the welding industry is witnessing advancements with the implementation of intelligent robotics. These innovations are transforming traditional practices and elevating performance benchmarks. Skilled welders can now leverage robotic technologies alongside tried-and-true hand tools like the swing welding dolly to achieve unprecedented accuracy and productivity. As organizations continue to promote and protect the robotics industry worldwide, understanding these evolving standards becomes vital for professionals aiming to stay competitive in a technologically advancing field.

This bar chart illustrates the performance metrics of swing welding dollies based on key dimensions that affect their usability in the industry. Each dimension is rated on a scale from 1 to 10, helping users understand where the swing welding dolly excels and where improvements can be made.

When considering the effectiveness and durability of a swing welding dolly, material selection plays a crucial role. The choice of materials can significantly influence how well the dolly performs under various conditions, including temperature fluctuations and exposure to different welding processes. For instance, high-quality steel or aluminum alloys can enhance the dolly's structural integrity, providing both strength and resistance to wear and tear. Additionally, using materials with better heat resistance can prevent deformation during intense welding operations, ensuring consistent alignment and support for the workpiece.

Moreover, the surface finish and treatment of the materials used in a swing welding dolly can also impact its lifespan and usability. A dolly with a rust-resistant coating will not only maintain its appearance over time but also minimize the risk of corrosion, which can compromise performance. Ultimately, selecting the right materials involves balancing factors such as weight, strength, and resistance to harsh environments. This careful consideration in the design phase enables welders to maximize the efficiency and longevity of their swing welding dolly, ultimately enhancing overall productivity in welding projects.

| Material Type | Effectiveness Rating (1-10) | Durability Rating (1-10) | Weight (lbs) | Cost ($) |

|---|---|---|---|---|

| Mild Steel | 8 | 7 | 30 | 50 |

| Aluminum | 7 | 6 | 20 | 70 |

| Stainless Steel | 9 | 9 | 25 | 150 |

| Cast Iron | 6 | 8 | 35 | 120 |

| Composite Materials | 8 | 7 | 15 | 90 |

When it comes to achieving optimal performance with a swing welding dolly, understanding the nuances of its use is essential. According to a report by the American Welding Society, proper techniques can increase welding efficiency by up to 30%. This emphasizes the importance of mastering the art of handling welding dollies. Professional welders recommend a firm grip and a steady hand while maneuvering the dolly to ensure smooth operations. Additionally, always keep the dolly's components clean and well-maintained to prevent any disruptions during work.

Another tip from industry experts involves the height adjustment of the swing welding dolly. Research indicates that ergonomically optimized work heights can reduce worker fatigue by as much as 25%, allowing for longer hours of effective work. Ensuring that the dolly is set at the appropriate height for the job not only enhances comfort but also supports better control over the welding process. Regularly maintaining the dolly, such as lubricating joints and checking for wear, can significantly prolong its lifespan and improve overall performance. By implementing these expert tips, welders can achieve top-notch results while maximizing their operational efficiency.