In the world of cutting technology, an Auto Cutting Machine stands out. These machines have transformed how industries approach precision cutting. They combine speed and accuracy, making them essential tools in various sectors like fashion, woodworking, and automotive manufacturing.

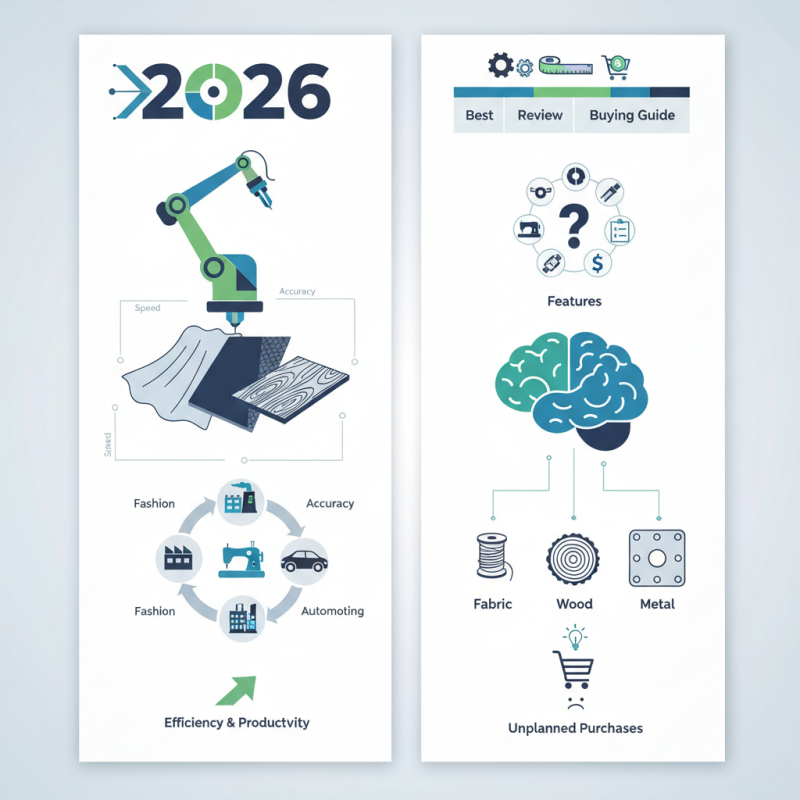

Choosing the right Auto Cutting Machine can be overwhelming. With so many options available, it’s easy to feel lost. You might wonder about the features that matter most or how to fit your budget while ensuring quality. It's crucial to reflect on your specific needs. What are you looking to cut? Is it fabric, wood, or metal? Each material requires different capabilities.

Investing in an Auto Cutting Machine isn't merely a financial decision. It represents a commitment to efficiency and productivity. A well-chosen machine can increase output and reduce waste. However, unplanned purchases often lead to dissatisfaction. Reflecting on your choices is essential in this journey to find the perfect machine.

Auto cutting machines have become essential tools in various modern industries. They streamline the production process and enhance precision. These machines are often used in textiles, packaging, and manufacturing. Their ability to cut materials quickly and accurately increases efficiency.

The importance of auto cutting machines lies in their versatility. They handle different materials, such as fabric, paper, and plastic. This allows industries to save time and reduce waste. However, not all auto cutting machines are perfect. Some may require frequent maintenance, which can disrupt production. Users must consider their specific needs and the machine's capabilities.

Moreover, the initial investment can be daunting. Some machines are costly, and businesses need to evaluate their return on investment. Training staff to use these machines effectively can also be challenging. It’s crucial for companies to weigh these factors before making a decision. The right choice can lead to significant benefits if managed well.

When choosing an auto cutting machine, several key features are essential. Look for precision and speed. These machines should offer quick cutting without compromising accuracy. A model with adjustable cutting speeds can be beneficial for different materials. Ensure that the blade type suits your projects, as this plays a crucial role in cutting performance.

Another important aspect is the machine's user interface. A user-friendly design enhances productivity. Touchscreens or clear displays simplify the operation process. It’s vital that you can easily switch settings. Don't overlook the size and weight of the machine. It should be portable yet stable enough for precise cuts.

Tips: Consider maintenance requirements. Regular upkeep enhances longevity. Check for easy access to parts that may need replacing. Always review customer feedback about durability and reliability. Look for machines that come with comprehensive warranties to protect your investment.

As we approach 2026, the auto cutting machine market is buzzing with new innovations. Many standout models promise precision and efficiency. These machines cater to various industries, including textile, leather, and packaging. Each machine boasts unique features that enhance productivity.

When selecting an auto cutting machine, consider your specific needs. The cutting speed and maximum material thickness are crucial factors. Some machines excel in versatility, while others are strictly designed for specific tasks. It is essential to align machine capabilities with your operational demands. Too often, users overlook these details, resulting in underperformance.

Top models in 2026 show promising advancements. Enhanced software interfaces improve usability, but not all users adapt quickly. Some may find it challenging to integrate these machines into their workflow. Evaluating the user experience will be key. Real-world testing showcases that even the best machines have learning curves. It's vital to reflect on what you truly need in an auto cutting machine before making a purchase.

In the expanding world of automatic cutting machines, performance and pricing play critical roles in buyer decisions. A recent industry report indicates that the global market for cutting machines is projected to reach $4.22 billion by 2026. This growth reflects a robust demand for advanced features and efficiency. In particular, systems offering multifunctional capabilities are gaining popularity among various sectors.

However, performance varies significantly across models. A comparative analysis shows that some machines cut through materials at speeds of over 100 inches per minute, while others struggle to reach 50 inches per minute. The most efficient models utilize advanced blade technology and automated settings. Yet, buyers often overlook the durability of components, which can lead to increased maintenance costs. This aspect can be a trade-off between initial savings and long-term investment.

Pricing can also be misleading. Entry-level machines may seem appealing but often compromise on quality. Reports reveal that middle-range options generally provide better reliability. Frequent users should consider the total cost of ownership, including maintenance and operational expenses. It's vital to recognize that not every high-priced machine guarantees superior performance, making informed choices essential in this competitive environment.

When choosing an auto cutting machine, consider your specific needs. Think about the materials you will work with. Different machines handle different materials better. Compatibility is key to efficient cutting.

Tips: Size matters. Ensure the machine fits your workspace. A compact unit may be easier to manage, but it can limit material size. Consider your project scale. Larger projects need robust machines. Think ahead about your cutting volume.

Not every machine suits every task. Some may lack features you desire. Research their capabilities. Look for user reviews. This will give insight into performance and reliability. Each user’s experience can differ greatly, and that’s important to acknowledge. Be cautious of machines with too many features. Complexity can lead to confusion.

| Model | Cutting Width | Cutting Speed | Material Compatibility | Price Range | User Rating |

|---|---|---|---|---|---|

| Model A | 60 cm | 600 mm/s | Fabrics, Leather, Vinyl | $1,000 - $1,500 | 4.5/5 |

| Model B | 80 cm | 500 mm/s | Textiles, Foam | $800 - $1,200 | 4.3/5 |

| Model C | 100 cm | 700 mm/s | Cardboard, Paper | $1,200 - $1,800 | 4.7/5 |

| Model D | 50 cm | 400 mm/s | Wood, Acrylic | $600 - $900 | 4.0/5 |

| Model E | 120 cm | 650 mm/s | Rubber, Leather | $1,500 - $2,200 | 4.6/5 |