In the world of welding, finding the right equipment is crucial. A Mini Welding Machine can be a great asset for both beginners and experienced welders. These compact tools are perfect for small projects and tight spaces. They offer versatility and ease of use, making them popular among hobbyists and professionals alike.

When searching for the best Mini Welding Machine, consider factors like power, portability, and features. Each model has unique advantages, but not all fit everyone’s needs. It can be challenging to find a machine that balances quality and price. Research and comparisons can often lead to confusion.

Some users report frustrations with certain models. Issues may arise with durability or ease of operation. Understanding which Mini Welding Machine aligns with your expectations is essential. Consider feedback from others. Reflect on your welding requirements before making a decision. Finding the perfect mini welder takes time and thought.

Mini welding machines have gained traction as essential tools in various industries in 2026. Their compact size does not compromise their power. In fact, industry studies indicate that the mini welding machine market is set to grow by 20% over the next five years. This growth highlights the increasing reliance on these machines in both professional and DIY settings. Many users appreciate their portability and versatility. These machines can efficiently handle tasks ranging from small repairs to intricate welding projects.

Tips: When choosing a mini welding machine, consider the power output. A machine with higher amperage often provides better performance on thicker materials. Always prioritize safety features. Reliable machines should come equipped with necessary safety protocols.

Additionally, mini welding machines are perfect for those new to welding. Their easier operation and lighter weight make them ideal for beginners. However, potential buyers should reflect on their specific needs. A machine intended for heavy-duty tasks may not be suitable if one only requires it for lighter work. Reviewing options can prevent unused purchases and regrets later on.

Tips: Look for user reviews before buying. Real-world feedback can reveal potential issues and hidden benefits that specifications may not cover.

When selecting a mini welding machine, it is vital to focus on key features. Power output plays a significant role in performance. Machines typically range from 120 to 240 volts. A higher output can handle thicker materials. Yet, choosing something too powerful for basic projects can be wasteful.

Portability is another major feature to consider. Many mini welding machines weigh less than 20 pounds. This makes them easy to transport. However, lightweight designs can sometimes sacrifice durability. Check for robust construction even in compact models.

Tip: Look for machines with adjustable settings. This allows for better control, ensuring you get precise welds every time.

Welding process types are essential as well. Options like MIG, TIG, and Stick welding offer different benefits. For beginners, MIG welding is often more user-friendly, while TIG welding provides more finesse. Each technique has its learning curve. It’s common for users to feel overwhelmed at first.

Tip: Don’t rush the learning process. Practice on scrap material before tackling important projects. It’s okay to make mistakes initially and learn from them.

| Feature | Description | Importance |

|---|---|---|

| Power Output | Measured in Amps, determines the thickness of metal you can weld. | High |

| Weight | Lightweight for portability, ideal for home and outdoor use. | Medium |

| Duty Cycle | Percentage of a 10-minute period that the machine can operate. | High |

| Type of Welding | MIG, TIG, or Stick - different techniques suitable for various applications. | High |

| Voltage | Input voltage compatibility; standard is 110V or 220V. | Medium |

| Adjustable Settings | Ability to fine-tune settings for different welding tasks. | High |

| Safety Features | Overload protection, thermal protection and safety interlocks. | Very High |

| Warranty | Length of warranty period offered by the manufacturer. | Medium |

When searching for the best mini welding machines in 2026, several brands stand out. These machines are compact yet powerful, perfect for both beginners and experienced users. Look for machines with dual voltage options. This versatility allows you to work on various projects. Check for models that support multiple welding types, including MIG, TIG, and stick welding. A combination of these features can vastly increase your capability.

Some machines may look appealing but lack in performance. It's crucial to read reviews from users. Some users reported issues with the duty cycle. A low duty cycle means you can only use the machine for a short time before it overheats. This can hinder progress on large projects. Additionally, pay attention to the machine's portability. A lightweight design can enhance your ease of use but may compromise sturdiness. Consider the trade-offs before making a decision. Your needs should guide your choice, considering both features and limitations.

When considering mini welding machines, performance and price are two main factors. Each machine has unique strengths. Some excel in portability, making them ideal for outdoor projects. Others offer superior power for heavier tasks. Understanding these differences is key to making the right choice.

Price ranges widely among mini welding machines. Budget-friendly options might sacrifice some features. They can be limiting if you need versatility. Higher-priced machines often include advanced settings and better build quality. However, not every expensive machine delivers better performance. It's crucial to compare features and user reviews.

Choosing a machine can be challenging. It’s tempting to go with a popular option. However, individual needs vary greatly. You might prioritize weight and ease of use over power. Or perhaps you need durability for constant usage. Assessing your specific needs can lead to better satisfaction, even if it takes time and careful consideration.

This chart compares the performance metrics and price range of various mini welding machines, focusing on factors such as amperage range, duty cycle, and price.

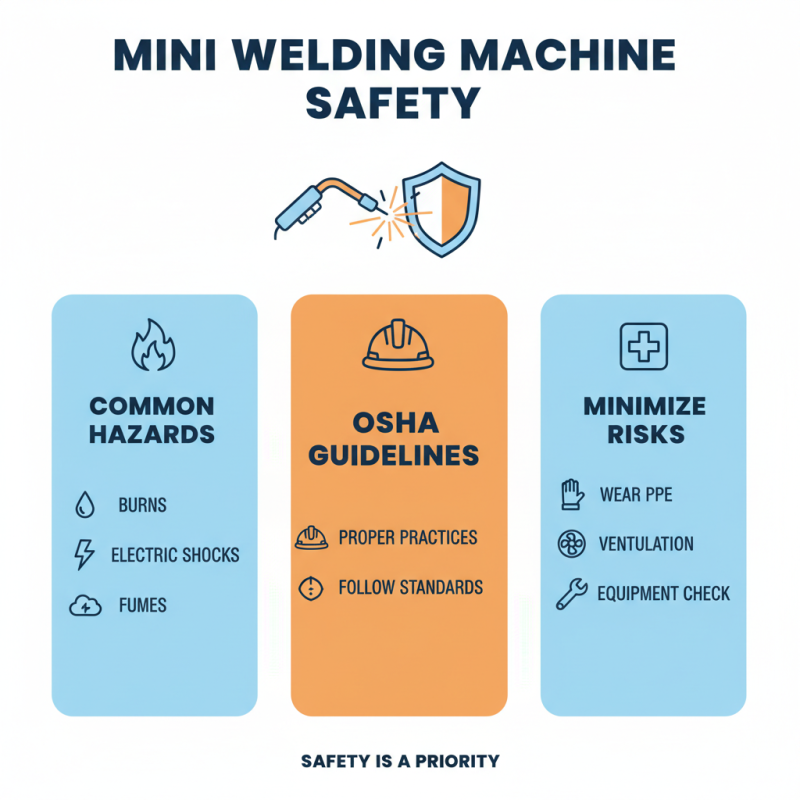

When using mini welding machines, safety should be a priority. The Occupational Safety and Health Administration (OSHA) reports that improper welding practices can cause accidents. Burns, electric shocks, and fumes are common hazards. It's crucial to follow safety standards to minimize these risks.

Wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and flame-resistant clothing. A recent industry survey found that over 30% of welders neglect basic PPE. This negligence can lead to severe injuries.

Tip: Always inspect your equipment before use. Look for frayed cords, leaks, or damage to ensure safe operation.

Additionally, proper ventilation is key. Welding produces harmful fumes that can affect your health. The American Welding Society recommends working in a well-ventilated area. If possible, use local exhaust ventilation to trap harmful gases.

Tip: Regular breaks can help reduce exposure to fumes. They allow you to clear your lungs and avoid long-term health issues.

Remember, safety requires constant vigilance. Reflect on your practices. You might discover habits that compromise your safety while welding.