In recent years, the realm of Welding Gas Cutting has seen rapid advancements. The global market for welding equipment is projected to reach USD 25.2 billion by 2026, highlighting the robust growth in this industry. Innovations in welding gas cutting techniques are crucial for enhancing efficiency and reducing costs in manufacturing.

Modern welding equipment incorporates smart technologies. These can offer real-time monitoring and detailed analytics. However, despite these advancements, many companies struggle to adapt to new methods. Training and skills gaps persist, which can hinder overall productivity. Industry reports suggest that up to 40% of workforce training remains outdated. This leads to difficulties in integrating advanced welding gas cutting technologies.

Sustainability is also at the forefront of industry discussions. New techniques aim to minimize waste and improve energy efficiency. Yet, few organizations have fully embraced these practices. Many remain reliant on traditional methods, even when they are less effective. Future trends will likely push for more eco-friendly options, but the transition is not guaranteed. Addressing these challenges will be vital for the evolution of Welding Gas Cutting in the coming years.

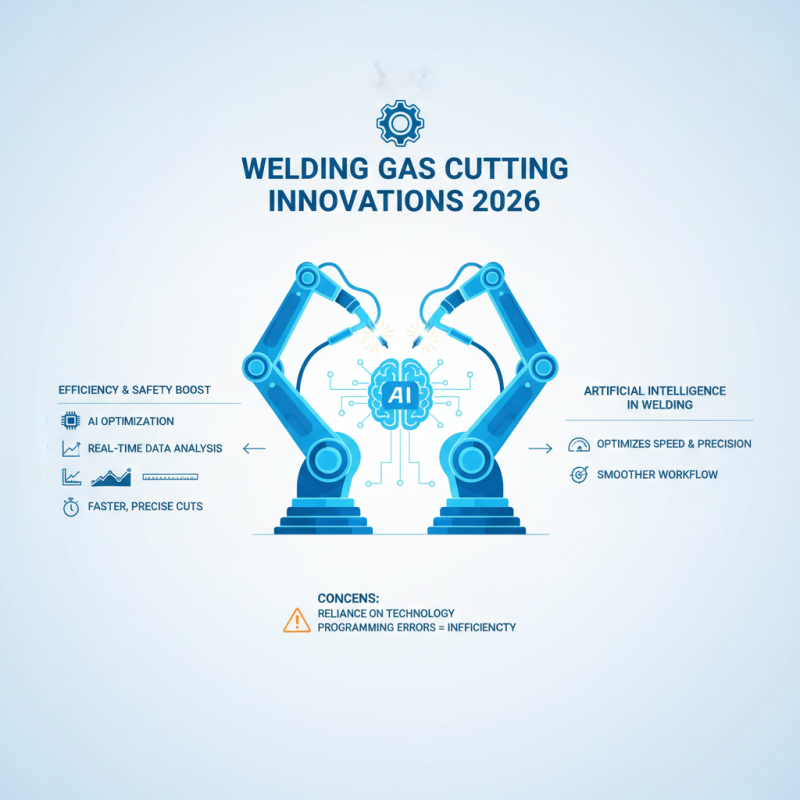

Innovations in welding gas cutting technologies are on the rise. In 2026, we expect significant advancements that enhance efficiency and safety in the industry. One such innovation is the use of artificial intelligence in welding processes. AI can analyze real-time data, optimizing settings for speed and precision. This creates a smoother workflow. However, there are concerns about the reliance on technology. Errors in programming could lead to inefficient cuts.

Another trend is the development of eco-friendly cutting gases. Traditional gases pose environmental challenges. New alternatives are being explored to reduce emissions. These gases offer similar performance while being safer for the planet. Still, the transition may not be seamless. Training workers to adapt to new materials could be a hurdle.

Moreover, automated welding equipment is becoming more sophisticated. With advancements in robotics, precision cuts can be achieved with minimal human intervention. While this increases productivity, it also raises questions about job security in the sector. Ensuring that workers are retrained is crucial. Balancing automation and employment will be a challenge for many industries.

The welding and gas cutting industry is on the brink of innovation. New equipment is designed to boost efficiency and precision. Laser cutting technology is emerging as a game changer. This method offers cleaner cuts and reduced heat distortion. It can run at high speeds with minimal setup time.

Automation is another key trend in equipment advancements. Robotic welding stations are gaining popularity. They can improve accuracy and consistency in production. Automation also reduces operator fatigue over long operations. However, systems can be complex, requiring ongoing training.

Portable cutting tools are becoming more user-friendly. Lightweight designs allow for easier handling in tight spaces. Yet, some users find it difficult to adjust settings. Balancing ease of use with advanced functionality is challenging. Finding the right tool for specific applications remains a question many face.

Sustainability is becoming increasingly important in welding gas cutting practices. As industries move toward greener solutions, new techniques emerge. Traditional methods often rely on fossil fuels, which contribute to greenhouse gas emissions. Switching to cleaner alternatives can significantly reduce the environmental impact.

Incorporating renewable energy sources is one trend. Solar and wind power can provide energy for welding applications. This shift not only helps the planet but can also lower energy costs in the long run. Companies should explore energy-efficient equipment. These tools often consume less gas and operate with increased precision.

Tips: Regular maintenance of your equipment can prevent inefficient fuel use. Tracking energy consumption helps identify areas to improve. Consider training sessions on eco-friendly practices for your team. This investment can lead to a more sustainable operation.

Additionally, recycling materials used in gas cutting is essential. Practicing efficient waste management reduces the overall footprint of welding operations. Some organizations are already implementing closed-loop systems. However, many still struggle with integrating these practices effectively. Addressing this gap will be crucial for advancing sustainability in the industry.

Bar chart represents the percentage share of different sustainability trends in welding gas cutting practices for the year 2026. The data reflects the increasing focus on eco-friendly technologies and practices in the welding industry.

The integration of automation in welding gas cutting techniques is reshaping the industry. Automated systems enhance precision, ensuring clean cuts every time. Robots can consistently follow complex designs without fatigue. This technology reduces human error and increases production speed. It’s fascinating to see how machines can outperform manual efforts in many ways.

However, not every automated solution is flawless. Sometimes, they may struggle with intricate or unexpected tasks. Operators must still supervise and intervene when issues arise. Training is essential for workers to understand automated systems. A balance between human oversight and machine efficiency remains vital.

There are also concerns about the high initial costs of automation. Smaller shops may hesitate to adopt these technologies due to financial constraints. The transition can be challenging, requiring time and resources. Yet, the long-term benefits often justify the investment. Embracing these changes is essential for companies to remain competitive. Automation in welding gas cutting is an evolving story, filled with opportunities and challenges.

As the welding gas cutting industry evolves, workforce skills and training must adapt. New technologies emerging in 2026 will require workers to have a diverse skill set. It's not just about mastering traditional techniques anymore. Understanding advanced equipment and automation is vital.

Training programs must focus on practical experience. Simulated environments can help prepare workers for real-world challenges. They need to practice using the latest tools safe and efficiently. However, many training centers struggle to keep up with the rapid advancements in technology. This gap can lead to a skills shortage.

Soft skills are also important in this field. Communication and teamwork will play a significant role in success. Workers need to collaborate on complex projects. Yet, many programs overlook these aspects, concentrating solely on technical skills. Addressing this imbalance is crucial. The future workforce must be well-rounded to thrive in the welding gas cutting industry.