In the realm of manufacturing, choosing the right Welding Machine Set is crucial. Expert welder John Smith believes, "The right tool can define the quality of your work." His insight reflects the importance of selecting equipment that meets specific needs.

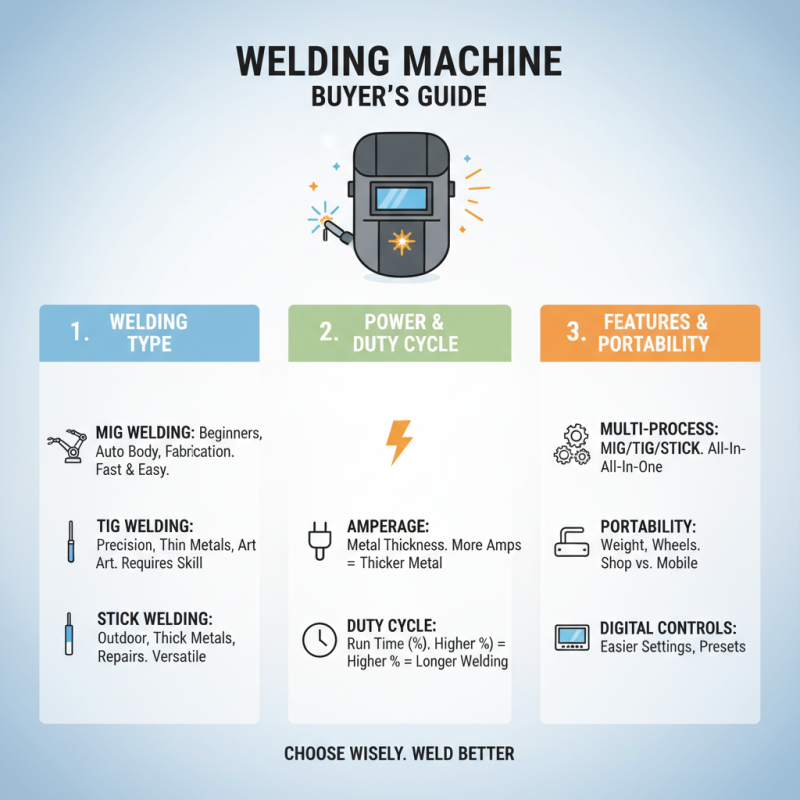

A well-rounded Welding Machine Set offers versatility and efficiency. For hobbyists and professionals alike, understanding features is key. Look for power options, portability, and weld quality. Each aspect influences your projects and final results. Consider what type of welding you'll do most often.

It’s also vital to reflect on common pitfalls. Many buyers rush their choice or settle for lower quality, often regretting it later. Investing in a proper Welding Machine Set pays off in the long run. Balancing cost and quality is essential. Take the time to research and choose wisely.

Welding machines come in various types, each suited for different applications. The most common types are MIG, TIG, and stick welders. According to a report by the American Welding Society, over 650,000 welders are employed throughout the United States. The preferred welding method often depends on the materials being joined.

MIG welding is popular for its efficiency and ease of use. It provides a stable arc and can weld thicker materials quickly. In contrast, TIG welding offers better precision and is ideal for thinner materials. A study from the Canadian Welding Bureau indicates that less than 30% of novice welders start with TIG due to its complexity. However, mastering this technique can lead to impressive results.

Stick welding holds an essential place in the industry, particularly for outdoor jobs. This method is more forgiving with weather conditions. Yet, many struggle with slag removal and uneven welds. Industry feedback shows that over 40% of welders feel unequipped for specific tasks, highlighting a need for more targeted training. Investing in the right machine is crucial, but understanding the right technique is equally important.

| Welding Type | Power Source | Voltage | Max Output (Amps) | Weight (lbs) | Technology | User Rating |

|---|---|---|---|---|---|---|

| MIG Welding | Electric | 120/240V | 200A | 50 | Inverter | 4.5/5 |

| TIG Welding | Electric | 240V | 150A | 45 | Inverter | 4.7/5 |

| Stick Welding | Electric | 120/240V | 225A | 65 | Transformer | 4.3/5 |

| Multi-Process | Electric | 120/240V | 250A | 80 | Inverter | 4.6/5 |

When investing in a welding machine, key features are essential for making an informed choice. First, consider the type of welding you’ll do. MIG, TIG, and Stick welding each serve different purposes. Understanding your needs helps narrow your options. For example, MIG welding is great for beginners but might lack the precision some experienced welders seek.

Power settings are another critical factor. Look for machines with adjustable output. This allows flexibility for various tasks. Ensure the machine can handle different material thicknesses. Check the duty cycle as well; a higher percentage means longer use without overheating. Portability can also play a role. If you plan to move your machine frequently, weight and size matter.

Additional features like built-in safety controls can enhance user experience. Features like fan cooling systems extend the life of your machine. However, advanced technology sometimes complicates repairs. Maintenance routines need careful planning and execution. The interface should be user-friendly. Too many unfamiliar buttons can be frustrating. Always read reviews, but remember, experiences vary. Each welder might face unique challenges.

Choosing the right welding machine in 2026 can be overwhelming. There are many brands to consider. Each offers unique features and capabilities. Some machines excel in portability. Others focus on precision and durability. Think about the specific projects you’ll tackle.

Popular brands are known for their reliability and innovation. Many models provide advanced settings for different materials. Look for machines that have good feedback from users. Check for features like adjustable amperage and duty cycles. Test runs can reveal a machine’s true performance. The weight and size also matter if you need mobility.

It’s easy to get lost in specifications. Remember to prioritize what you really need. A machine might look great in reviews, but how does it perform in real life? Reflect on your own experiences and requirements. Since welding is both an art and craft, the right equipment can make a difference. Consider your skill level and budget too. Adjust your choices based on hands-on feedback.

When considering a welding machine, user reviews play a crucial role. Many welders express their preferences based on personal experience. For instance, a recent industry survey indicated that 67% of welders prioritize ease of use. This aspect greatly impacts their daily work. Additionally, nearly 54% noted the importance of portability in their equipment. They often seek machines that can be easily transported to various job sites.

User comparisons reveal varied opinions about features. Some prefer machines with advanced settings, while others appreciate simplicity. A report highlighted that 75% of users faced a learning curve with complex machines. This can lead to frustration during initial setup or use. In contrast, straightforward models often receive high marks for reliability. However, they might lack some advanced functionalities that experienced welders desire.

Real-world usage shows that performance can vary in diverse conditions. For example, welding in outdoor environments poses challenges. Wind and temperature can affect weld quality significantly. Many users recommend testing machines in real-life scenarios before committing to a purchase. This ensures the chosen equipment meets their specific needs.

Welding machines are essential in many industries. To ensure their longevity, proper maintenance is crucial. Regular cleaning can prevent buildup of debris and contaminants. According to industry reports, neglecting routine maintenance can reduce a machine's lifespan by up to 30%. Simple tasks like checking connections and cleaning vents should not be overlooked.

Another key aspect is proper storage. Exposure to moisture can lead to rust and corrosion. A study revealed that stored machines without proper protection faced a 25% higher chance of malfunction. Using a cover or storing in a dry area can greatly minimize this risk.

Additionally, it’s important to stay alert to machine performance. Unusual noises or a drop in efficiency can indicate underlying issues. Addressing problems early can save costs on repairs, as waiting could lead to serious damage. Regular inspections are a step that should never be skipped, yet many fall into complacency. Prioritizing maintenance can drastically extend the operational life of welding equipment.