In the realm of modern manufacturing, Automatical Welding has emerged as a transformative technology that is redefining the industry's landscape. As companies increasingly seek efficiencies and precision in their welding processes, Automatical Welding stands out as a game-changer. According to Dr. Emily Carter, a leading expert in welding technology, "Automatical Welding not only enhances the quality of welds but also significantly reduces production time and costs." Her insights underscore the profound impact this technology has on operational efficiency.

This innovative approach involves the use of automated systems and robotics to perform welding tasks, decreasing the variability associated with manual welding methods. With its ability to consistently produce high-quality welds at a faster pace, Automatical Welding is revolutionizing how manufacturers approach production challenges. As industries continue to embrace automation, the future of manufacturing looks increasingly bright, driven by such advancements.

As we delve deeper into the specifics of Automatical Welding, we'll explore how this technology is being adopted across various sectors and the benefits it brings to manufacturers aiming for excellence in an ever-evolving marketplace.

Automatical welding, also known as automated welding, refers to the use of machinery and robotic systems to perform welding tasks without direct human intervention. This process harnesses advanced technologies, such as computer controls and programmable logic controllers, to execute welding operations with precision and consistency. Unlike manual welding, where human skill and experience play a crucial role, automatical welding enhances manufacturing efficiency by minimizing errors and increasing production speeds.

The implementation of automatical welding has transformed various industries, including automotive, aerospace, and construction. This method not only ensures a higher level of weld quality but also reduces production costs by optimizing time and resources. Automated systems can work continuously, thereby increasing throughput and enabling manufacturers to meet high demand levels efficiently. As industries continue to embrace technological advancements, automatical welding stands at the forefront, revolutionizing traditional manufacturing processes and setting new standards for quality and efficiency.

Automatical welding has transformed manufacturing processes by integrating various technologies that enhance precision and efficiency. Key innovations driving this revolution include advancements in ARC, resistance welding, gas welding, and solid-state welding techniques. Each of these methods plays a significant role in the automation landscape, making it easier to handle complex structures and large-scale projects. For instance, ARC welding has evolved with sophisticated control systems that allow for consistent quality, while resistance welding integrates smart technology for real-time adjustments during the welding process.

The welding market is on an upward trajectory, with projections indicating robust growth in equipment and consumables across all welding types. The impact of the COVID-19 pandemic has also prompted a reevaluation of manufacturing practices, pushing industries towards greater automation. As businesses look to minimize disruption, technologies enabling automatical welding are becoming essential for maintaining competitive advantage. The rise of intelligent manufacturing showcases the need for tailored solutions, with companies increasingly adopting smart welding equipment that leverages data analytics and modeling, thus ensuring precision and efficiency in production lines.

| Technology | Description | Benefits | Application Areas |

|---|---|---|---|

| Laser Welding | Uses high-intensity laser beams to fuse materials. | Precision, reduced heat input, and minimal distortion. | Automotive, aerospace, and electronics. |

| TIG Welding (GTAW) | Involves a tungsten electrode to produce a weld. | High-quality welds with all metals, control of heat input. | Fabrication of stainless steel and aluminum components. |

| MIG Welding (GMAW) | Uses a wire feed as an electrode and a shielding gas. | Fast, versatile, and easy to automate. | Automotive and metal fabrication industries. |

| Electron Beam Welding | Uses a focused beam of electrons to create welds. | Deep penetration with minimal heat-affected zones. | Aerospace and nuclear applications. |

| Robotic Welding | Automated welding performed by industrial robots. | Increased efficiency, consistency, and safety. | Heavy industries including automotive and manufacturing. |

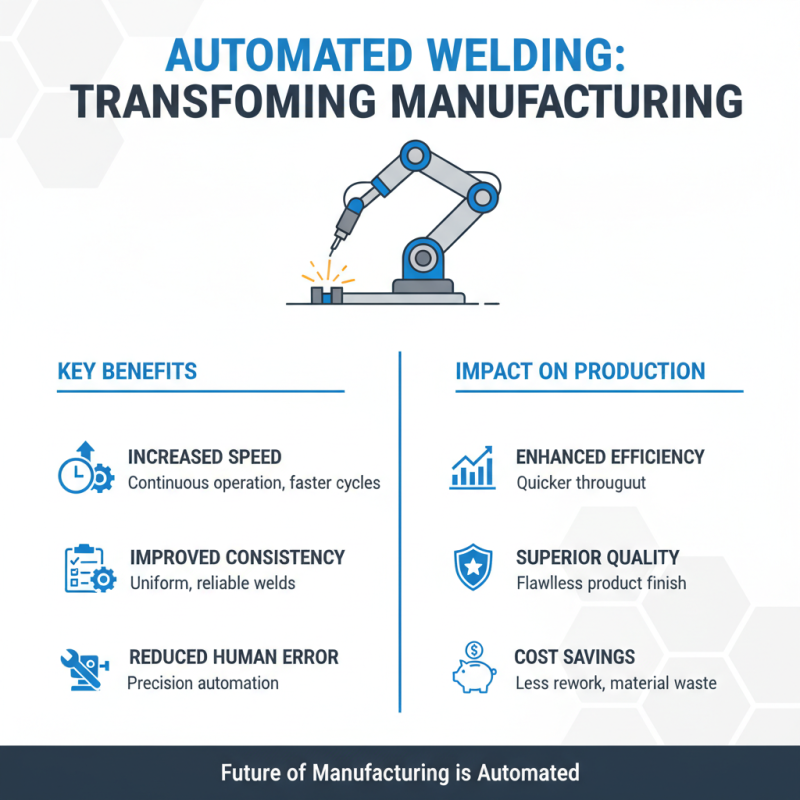

Automatical welding has emerged as a transformative force in modern manufacturing, offering numerous benefits that enhance production efficiency and product quality. One of the primary advantages is the significant increase in speed and consistency of welds. Automated systems can execute welding operations continuously, far surpassing the capabilities of manual welding. This not only accelerates production cycles but also minimizes human error, resulting in more uniform and reliable welds.

Another important benefit of automatical welding is the improved safety it brings to manufacturing environments. By utilizing machines for potentially hazardous tasks, the risk of workplace injuries decreases significantly. Workers can focus on overseeing processes instead of engaging in high-risk activities, thereby promoting a safer workplace. Furthermore, automated systems can operate in environments that are less suitable for humans, such as those involving extreme temperatures or toxic fumes, further enhancing overall safety in manufacturing operations.

In addition to safety and efficiency, automatical welding also allows for greater flexibility in design and manufacturing processes. With advanced programming capabilities, machines can be easily reconfigured to accommodate different projects, thus supporting a wider range of products without the need for extensive retooling. This adaptability is crucial for manufacturers aiming to stay competitive in a rapidly changing market.

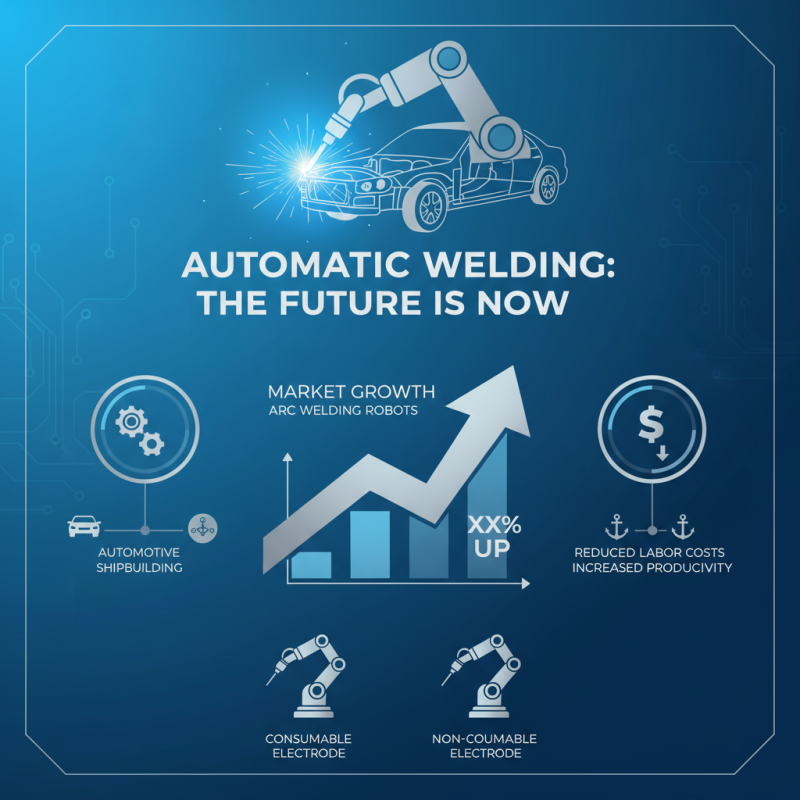

Automatical welding, a cutting-edge technology in the manufacturing sector, is being adopted across various industries due to its efficiency and precision. In the automotive industry, arc welding robots are particularly crucial, with market projections indicating substantial growth. The arc welding robot market is expected to witness significant expansions, driven by the increasing demand for automation solutions to enhance productivity and reduce labor costs. Companies are focusing on both consumable and non-consumable electrode arc welding robots to cater to diverse production needs, with applications spanning automotive assembly lines to shipbuilding operations.

Moreover, ultrasonic plastic welding machines are gaining traction, with a market size projected to grow from $320 million in 2022 to $550 million by 2030, representing a compound annual growth rate (CAGR) of 7.2%. These machines are essential in industries such as electronics and medical packaging, demonstrating the versatility of automatical welding technology. As the technology matures, integrating intelligent systems like collaborative welding robots will further transform production landscapes, enabling companies to achieve higher quality welds with greater consistency and less manual intervention. The rise in market demand underscores the importance of automatical welding in modern manufacturing operations.

The automatical welding technology is rapidly evolving, influenced by trends towards automation and smart manufacturing. Recent analyses indicate that the welding consumables market is set to experience significant growth, projected to reach a valuation of several billion dollars by 2025. Segmenting the market by type reveals substantial shares for solid wires, flux-cored wires, and welding rods, each catering to varying industrial needs and applications in automation environments.

The impact of COVID-19 further accelerated the adoption of these technologies, as manufacturers sought to minimize labor risks and enhance productivity through automation. With welding techniques like arc welding and resistance welding on the rise, companies are investing in training programs to cultivate skilled welders who can adapt to advanced systems. The intersection of education and new technologies is evident at institutions like Anhui Vocational and Technical College, which emphasizes smart production lines equipped with welding robots, preparing the next generation for a rapidly changing industry landscape.