The rise of Portable Mig Welders has transformed the landscape for DIY enthusiasts, enabling greater accessibility and versatility in welding projects. According to a recent report by the American Welding Society, over 50% of hobbyists and small business owners are now gravitating towards portable welding solutions, underscoring a notable shift in industry preferences. The advantages of using a Portable Mig Welder extend beyond convenience; they offer improved ease of use, portability, and enhanced welding quality. With advancements in technology, these machines now feature user-friendly interfaces and lightweight designs, making them ideal for on-the-go repairs and fabrications. As DIY culture continues to flourish, understanding the benefits and functionalities of Portable Mig Welders will empower enthusiasts to tackle a wider range of projects, from automotive repairs to intricate metal art.

Portable MIG welders have revolutionized the way DIY enthusiasts approach welding projects. These compact machines typically weigh between 40 to 80 pounds, making them easy to transport and suitable for a variety of applications, from automotive repair to metal art creation. According to industry reports, the portable welding equipment market is expected to grow significantly, with projections indicating a CAGR of around 5.2% from 2021 to 2028. This trend highlights the growing popularity of these versatile tools among hobbyists and professionals alike.

One of the primary advantages of portable MIG welders is their user-friendly operation. Most models come with adjustable settings for voltage and wire speed, making them ideal for beginners while also offering the flexibility that seasoned welders appreciate. Furthermore, they are compatible with various materials, including steel, aluminum, and stainless steel. A survey conducted by the Welding Equipment Manufacturers Committee revealed that over 70% of users choose portable models for their ease of use and adaptability for on-site jobs.

**Tips:** When selecting a portable MIG welder, consider the duty cycle—this refers to how long you can weld before the machine needs to cool down. A welder with a high duty cycle (60% or more) is preferable for longer projects. Additionally, invest in quality protective gear, as safety should always be a priority when working with welding equipment.

| Feature | Description | Advantages |

|---|---|---|

| Portability | Lightweight design and easy to carry. | Ideal for on-site projects and outdoor work. |

| Ease of Use | User-friendly controls and setup. | Suitable for beginners and quick tasks. |

| Versatility | Can weld various types of metals and thicknesses. | Wide range of applications for different projects. |

| Power Options | Operates on standard outlets or gas cylinders. | Flexibility for indoor and outdoor usage. |

| Affordability | Cost-effective compared to traditional welders. | Great value for DIY enthusiasts and hobbyists. |

Working with portable MIG welders can offer immense benefits for DIY enthusiasts, enabling easy use in various projects. However, safety should always be the foremost consideration. According to the American National Standards Institute (ANSI), over 40% of welding-related accidents stem from improper safety practices. Therefore, understanding essential safety tips is crucial for protecting oneself while enjoying the art of welding.

First and foremost, personal protective equipment (PPE) is a must. This includes a welding helmet with appropriate filters to shield eyes from harmful UV rays, gloves to protect hands from burns and abrasions, and flame-resistant clothing. The National Institute for Occupational Safety and Health (NIOSH) stresses that wearing proper PPE can reduce injury risk by as much as 55% in welding operations. Additionally, ensuring proper ventilation is key, as welding produces hazardous fumes and gases. Maintaining an adequate airflow around the work area can mitigate these risks significantly.

Furthermore, it’s vital to conduct a thorough inspection of the portable MIG welder before use. Checking for any signs of wear or malfunction can prevent accidents due to equipment failure. The Welding Equipment Manufacturers Committee (WEMC) recommends regular maintenance and adherence to manufacturer guidelines to extend the lifespan and reliability of the welder. By following these essential safety tips, DIY enthusiasts can enjoy the advantages of portable MIG welders while minimizing potential hazards.

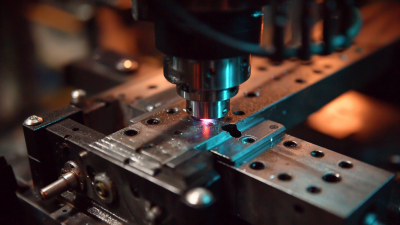

Setting up your portable MIG welder can be a straightforward process if you follow a few key steps. First, gather all the necessary tools and materials, including your welder, safety gear, shielding gas, and welding wire. Ensure you have a clean workspace that is well-ventilated to promote safety while welding. Start by connecting the gas cylinder to the regulator and then to your welder, ensuring all fittings are secure to prevent any leaks.

Next, load the welding wire into the welder's spool. Open the compartment, place the spool correctly, and thread the wire through the gun and nozzle. Adjust the tension settings according to the diameter of the wire for optimal feed. It's also critical to set the correct voltage and wire feed speed on your welder, as these settings can vary depending on the thickness of the material you're working with. Once everything is set up, test the machine on a scrap piece of metal to ensure it’s functioning correctly before you dive into your DIY project.

Portable MIG welders have become essential tools for DIY enthusiasts, enabling them to tackle a variety of projects with ease and precision. One common project is home repair, where small fabrications are often necessary. Whether it’s fixing a broken gate or patching up a metal fence, the lightweight and maneuverable nature of portable welders makes them ideal for such tasks. With their user-friendly design, even those new to welding can achieve strong, clean welds with practice.

Another exciting application for portable MIG welders is building custom furniture. Many DIY enthusiasts are exploring metalworking to create unique pieces that stand out in their homes. From coffee tables to outdoor chairs, the versatility of a MIG welder allows for intricate designs and robust construction. Additionally, portable welders can be used for automotive repairs or modifications, making them valuable for those who enjoy working on their vehicles. With a portable welder, DIY projects become more accessible and fulfilling, empowering enthusiasts to bring their creative visions to life.

Portable MIG welders have become essential tools for DIY enthusiasts, offering both convenience and versatility. Whether you're tackling home improvement projects or working on your vehicle, these welders provide an efficient solution to your welding needs. Their lightweight and compact design allows for easy transportation, making them ideal for outdoor jobs or tight spaces.

To maintain your portable MIG welder in top condition, regular maintenance is key. One important tip is to clean the nozzle and contact tip frequently to prevent spatter build-up, which can lead to welding defects. Additionally, always check the gas connections and replace any worn hoses to ensure a steady flow during operation. Properly storing the welder in a dry and secure environment will protect it from damage and extend its lifespan.

Another vital aspect of maintenance is inspecting your welder's electrical components. Look for any frayed wires or loose connections, as these can affect performance and safety. Keeping the welder's user manual handy for troubleshooting can save you time and effort when issues arise. By following these tips, you can keep your portable MIG welder ready for any project that comes your way.