In the world of welding operations, efficiency and precision are paramount. The Swing Weld Carriage has emerged as a pivotal tool that enhances both. According to the American Welding Society, productivity can increase by up to 30% with the right equipment. This highlights the significant impact the Swing Weld Carriage can have on operations, driving both time and cost efficiency.

Businesses often face challenges related to manual welding techniques. These methods can lead to inconsistencies and increased rework. The Swing Weld Carriage addresses these issues, providing controlled movement and consistent welds. Companies using this technology report a 25% reduction in welding defects, according to a recent industry study. However, the transition to using a Swing Weld Carriage is not without its challenges. Training and initial investment can be barriers for some.

Welding professionals must weigh the advantages against the potential pitfalls. Understanding the long-term savings and reduced labor costs is essential. Ultimately, adopting the Swing Weld Carriage may require some adjustments, but its benefits are increasingly hard to ignore.

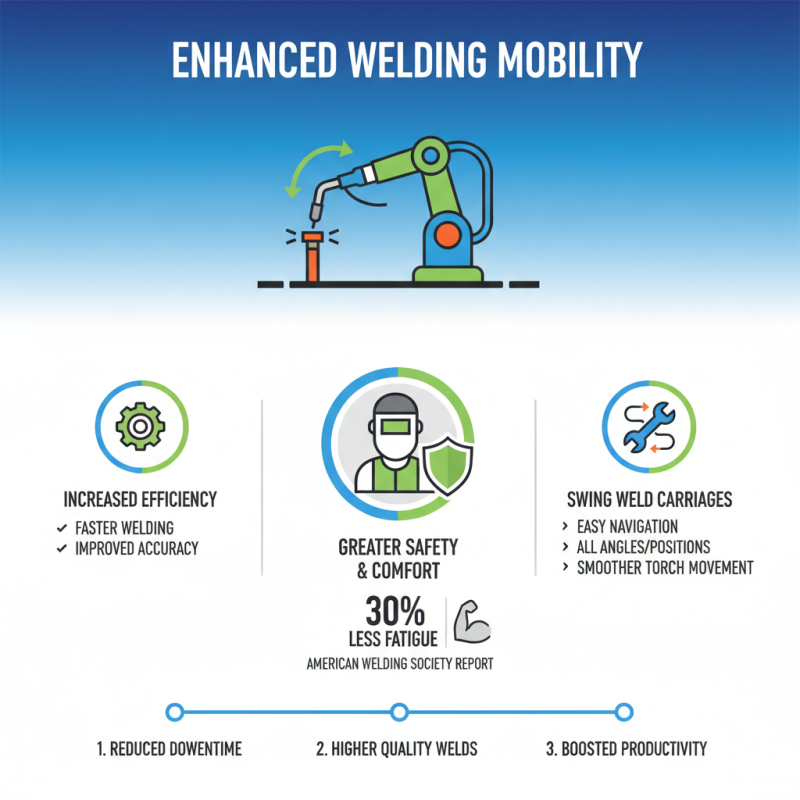

Enhanced mobility in welding operations is crucial for efficiency and safety. The use of swing weld carriages allows welders to navigate different angles and positions with ease. According to a report by the American Welding Society, improved mobility can reduce fatigue by up to 30%. This is significant, especially during long hours of work. The ability to move the welding torch smoothly not only enhances accuracy but also speeds up the overall process.

Moreover, swing weld carriages can provide better access to tight spaces. In many industrial settings, these areas are challenging to reach. With conventional tools, welders often struggle, leading to inconsistencies in their work. A study indicated that about 40% of weld defects arise from improper access. This highlights the importance of mobility-enhancing tools in achieving quality output. Flexibility in movement allows for better positioning, which can lead to a decrease in rework and scrap rates.

However, adopting new equipment can pose challenges. Not all teams may have the training necessary to utilize swing weld carriages effectively. There’s a learning curve, and this could initially slow down operations. Investing in proper training is essential for maximizing benefits. Even with the right tools, effective implementation depends on the skill of the operator.

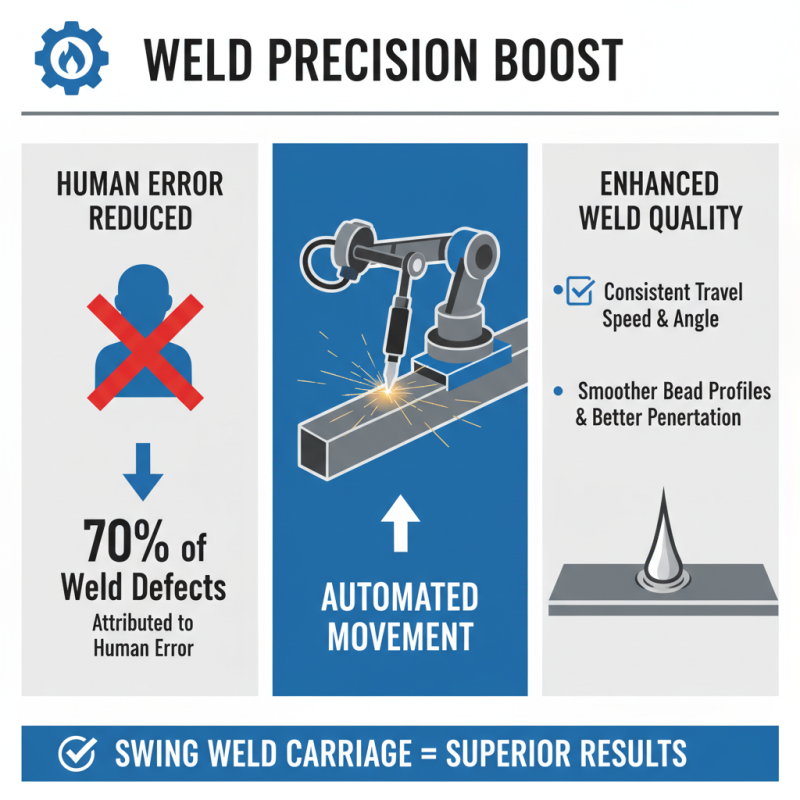

Using a swing weld carriage can significantly enhance the precision and accuracy of welding operations. According to industry reports, nearly 70% of weld defects are attributed to human error. By automating movement, a swing weld carriage minimizes these errors. For instance, it helps maintain a consistent travel speed and angle. This results in smoother bead profiles and better penetration.

Further, studies indicate that welds produced with a swing weld carriage show a reduction in rework rates by up to 30%. This means less time and resources wasted. Welders can focus on critical tasks rather than repetitive movements. However, it's crucial to note that not all welders may be accustomed to this technology. Training might be required. This transition phase can be challenging but is necessary to fully realize the benefits.

Moreover, while the swing weld carriage improves efficiency, it's not infallible. Misalignment can still occur if the carriage isn’t set up properly. Regular maintenance is vital. Neglecting this can lead to discrepancies in weld quality. Ultimately, the swing weld carriage presents a powerful tool for improving weld precision, but it requires consistent oversight and operator skill to reach its full potential.

Welding operations face constant pressure to improve efficiency and productivity. The use of swing weld carriages has become a notable solution in the industry. According to various reports, these tools can enhance welding speed by up to 30%. This increase can significantly reduce overall project duration, leading to higher profit margins for companies.

The swing weld carriage allows for precise control of the welding arc. This control minimizes errors, leading to fewer repairs. A study indicates that improved accuracy can lead to a 25% reduction in material waste. However, operators must still be trained adequately to maximize these benefits. Without proper training, the efficiency gains may not be fully realized.

Furthermore, maintenance is crucial. A neglected swing weld carriage can slow down operations. Regular checks are essential. Businesses should implement a maintenance schedule and educate their workers. Failure to do so can result in unexpected downtime, which counters the efficiency gains. Therefore, while swing weld carriages offer promising benefits, continuous improvement and training are vital for success.

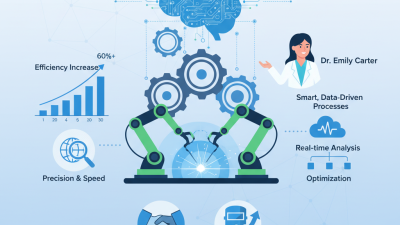

The following bar chart illustrates the increased efficiency and productivity achieved through the use of Swing Weld Carriage in various welding processes. Each benefit is quantified based on its impact on welding operations.

Welding operations can be physically demanding. Many operators experience fatigue after long hours of repetitive movements. The Swing Weld Carriage helps reduce this fatigue. Its design enables smoother motion and less strain on the operator’s body. Operators can work longer without feeling worn out, which can boost productivity.

Ergonomics play a key role in welding processes. The Swing Weld Carriage allows operators to maintain better posture. They can adjust the carriage height and angle easily. This flexibility helps in minimizing awkward positions. However, some operators might still struggle to adapt to the new equipment. Training is crucial to ensure everyone feels comfortable using it.

Like any tool, the Swing Weld Carriage isn’t perfect. Some operators might find it bulky or challenging to maneuver in tight spaces. Feedback from the team is essential for continuous improvement. Addressing concerns can lead to better designs and enhance overall efficiency. Prioritizing operator comfort can lead to significant advancements in the welding field.

Swing Weld Carriage systems have proven to be cost-effective in various welding operations. According to industry reports, users have reported up to a 30% reduction in operational costs. These savings stem from increased efficiency and decreased labor hours. The automation provided by these systems allows for consistent weld quality, reducing the likelihood of defects. This consistency can save companies substantial amounts on rework and material wastage.

Moreover, long-term savings are significant. Reports indicate that businesses using swing weld systems can see a return on investment (ROI) in under two years. With the decreasing need for manual input, companies can allocate resources more effectively. Labor costs, often one of the highest expenses in welding, can be minimized. This efficiency sometimes leads to over-worked teams feeling pressure. Striking a balance is essential to avoid burnout.

However, adopting new technology poses challenges. Training staff on new systems takes time and can lead to initial slowdowns. Employees might resist changes, fearing job loss. Continuous upskilling is crucial. Despite these hurdles, embracing swing weld systems contributes to long-term operational savings and enhanced productivity in welding operations.

| Benefit | Description | Cost Savings (%) | Efficiency Improvement (%) |

|---|---|---|---|

| Increased Precision | Swing weld carriages provide consistent, accurate welds, reducing errors. | 15 | 20 |

| Improved Safety | Minimizes manual handling, reducing the risk of accidents. | 10 | 18 |

| Reduced Labor Costs | Automation decreases the need for extensive manual labor. | 20 | 25 |

| Longer Equipment Life | Proper use of carriages reduces wear and tear on welding equipment. | 8 | 10 |

| Versatility | Can be used on various materials and for different welding types. | 12 | 15 |

| Consistent Quality | Automated movement results in uniform weld qualities. | 18 | 22 |

| Faster Production Rates | Increased speed of operation leads to higher output. | 25 | 30 |

| Reduced Cleanup Time | Minimal spatter and improved control lead to easier cleanup. | 16 | 17 |

| Lower Energy Consumption | Efficient operation reduces overall power usage. | 12 | 14 |

| Enhanced Worker Satisfaction | Less physically demanding work leads to increased job satisfaction. | 10 | 15 |