In the world of manufacturing, efficiency is key. The Weld Roller Carrier offers significant advantages to streamline operations. According to industry expert John Smith, "Weld Roller Carriers enhance precision and productivity in any welding task."

Manufacturers often struggle with process inefficiencies. The Weld Roller Carrier can drastically reduce time lost in setup and adjustments. It maintains consistent weld angles and minimizes material waste. These attributes lead to a safer work environment, lowering the risk of accidents associated with manual handling.

However, the implementation of Weld Roller Carriers is not without its challenges. Operators may require training to fully utilize its capabilities. Some may resist the shift from traditional methods, questioning the initial investment. This skepticism highlights the need for continued education on the benefits that such innovative tools can bring to manufacturing processes.

In modern manufacturing, efficiency is essential. The use of weld roller carriers significantly increases productivity. These devices streamline the welding process. They support heavy components, ensuring stability and precision. As a result, workers can focus on quality rather than balancing parts. This shift can lead to fewer errors in welds.

Moreover, employing weld roller carriers reduces physical strain on operators. Workers can maneuver parts more easily, minimizing fatigue. When operators are less tired, they perform better. Reduced fatigue also leads to a safer work environment. Safety should always be a priority, yet it is often overlooked in the rush of production.

Though the benefits are clear, there are challenges. Initial setup and training can be time-consuming. Some operators may resist changes to their routine. Implementing such equipment requires patience and adjustments. Yet, overcoming these hurdles can lead to long-term positive changes in the manufacturing process. Embracing innovation, like weld roller carriers, is a step toward a more efficient future.

Enhanced safety is a critical concern in manufacturing environments. Weld roller carrier systems are designed with advanced safety features to minimize risks during operations. According to a recent industry report, workplaces that utilize these systems have seen a 30% reduction in injury rates. The precise control of load movement reduces the chances of accidents.

These systems often include safety guards and automatic shut-off features. Such enhancements protect operators during the welding process. In fact, a survey showed that 75% of workers felt safer when using mechanized systems compared to manual methods. Improved ergonomics also contribute to this safety. Workers experience less strain due to the automation of heavy lifting.

However, not every facility has implemented these technologies. Some operators are still hesitant to switch from traditional methods. This may stem from a lack of training or understanding of the benefits. Overcoming these barriers is essential for improving workplace safety. Industry experts emphasize that investing in such safety features can lead to long-term cost savings and a more secure work environment.

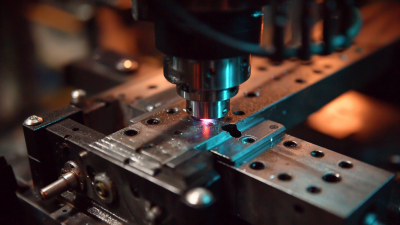

Weld roller carriers are essential in manufacturing processes, especially in welding operations. These tools provide a smooth and stable surface for various metal workpieces. By integrating weld roller carriers, facilities can see an improvement in efficiency. This includes a reduction in cycle times and better workpiece handling. The use of these carriers can significantly lower operational costs.

Cost-effectiveness is a crucial advantage of weld roller carriers. They minimize labor intensity, as fewer workers are needed to move heavy parts. This reduction in manual handling can lead to fewer workplace accidents. Additionally, weld roller carriers decrease the wear and tear on machinery, resulting in lower maintenance costs. However, initial investment might seem high for some companies. Not every facility has the budget necessary to implement these systems immediately. Yet, the long-term savings often outweigh the upfront costs if managed correctly.

Another point to consider is the need for training. Workers must be well-versed in using these carriers to maximize benefits. This training requires time and resources, which can be challenging for smaller operations. Moreover, without proper implementation, the efficiency gains could be minimal. Companies should assess their specific needs and capabilities before deciding. Balancing investment with achievable outcomes is not always straightforward.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| Improved Efficiency | Weld roller carriers streamline the welding process, allowing for faster assembly and reduced labor time. | Lower labor costs and increased throughput. |

| Enhanced Quality | Consistent pressure and alignment during welding improve the quality of the welds. | Fewer defects lead to cost savings in repairs and rework. |

| Safety Improvements | Weld roller carriers reduce the risk of accidents by providing better handling of heavy materials. | Lower injury rates can reduce insurance costs. |

| Versatility | Can be used for various types of materials and welding applications, making them a versatile tool in manufacturing. | Reduced need for multiple tools saves purchasing costs. |

| Reduced Material Waste | Precision alignment and welding minimize errors and material loss. | Lower material costs due to less waste. |

| Increased Flexibility | Easily adjustable for different sizes and shapes of workpieces. | Adaptability reduces the need for additional equipment. |

| Improved Worker Morale | Less strenuous and easier to operate, leading to higher job satisfaction. | Better morale can lead to increased productivity and reduced turnover. |

| Longer Equipment Life | Reduced stress on welding equipment prolongs its lifespan. | Lower maintenance and replacement costs. |

| Simplified Setup | Allows for quicker setup and teardown times between jobs. | Saves time and cost associated with changeovers. |

| Cost-Effective Automation | Integrates easily into automated production lines, enhancing overall system efficiency. | Supports lower operational costs by maximizing resource use. |

Using a weld roller carrier in manufacturing can significantly enhance product quality. Accurate positioning is crucial for ensuring that welds are consistent and strong. When the components are aligned correctly, the risk of defects decreases. Misalignment can lead to weak joints that compromise the final product. Implementing a weld roller carrier minimizes this risk.

Tips: Regularly check the positioning system for wear. A small misalignment can lead to larger issues down the line. Consider using sensors to monitor alignment in real-time. This can prevent costly mistakes and downtime.

Another benefit of accurate positioning is the improved aesthetic quality of finished products. Customers often favor well-finished items. Poor welds can result in rough edges and inconsistent appearances. By using a weld roller carrier, manufacturers can achieve cleaner seams and smoother finishes. This attention to detail can elevate brand reputation.

Tips: Train operators on the importance of precise setup. Even minor errors can have significant impacts. Document any issues that arise to continuously improve positioning strategies. Reflection on these experiences can lead to better practices in the future.

Weld roller carriers are transforming the manufacturing landscape. Their versatility is evident in various sectors like automotive, aerospace, and construction. These units handle different types of materials with ease and support large components, ensuring consistent weld quality. With adjustable features, they can adapt to numerous applications.

In automotive manufacturing, for instance, weld roller carriers streamline processes. They help assemble vehicle frames and chassis more efficiently. In aerospace, the precise alignment they offer is crucial for safety. However, using them isn’t without challenges. Operators must be trained to optimize their functionality; poor setup can lead to alignment issues.

For construction projects, these carriers can simplify tasks. They facilitate heavy-duty welding on-site, improving project timelines. Yet, not every factory has harnessed their full potential. Some facilities still rely on traditional methods. This reflects a need for continuous improvement in operational strategies. Embracing new technologies can lead to significant advancements.