Welding Gas Cutting techniques have emerged as valuable assets in the realm of metal fabrication, significantly enhancing operational efficiency. As reported by the American Welding Society, the adoption of advanced gas cutting methods can reduce cutting times by up to 50%, allowing fabricators to complete projects more swiftly without compromising quality. Additionally, industry data indicates that businesses utilizing these techniques can achieve a 30% decrease in overall material waste due to more precise cutting capabilities. This efficiency not only leads to cost savings but also contributes to a more sustainable manufacturing process. As the demand for precision and speed in metal fabrication continues to rise, understanding the advantages of Welding Gas Cutting is crucial for professionals looking to optimize their operations and stay competitive in a rapidly evolving industry.

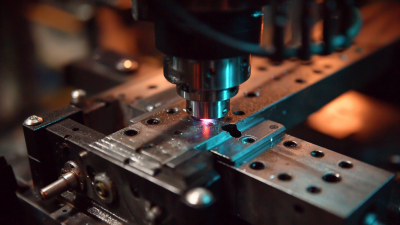

Gas cutting is an essential technique in metal fabrication that leverages the principle of oxidation to sever materials efficiently. This method involves the use of a high-temperature flame, typically generated by the combustion of oxygen and fuel gas, to melt and oxidize metal along a predetermined line. According to industry reports, gas cutting can achieve a cutting speed of up to 10 inches per minute on mild steel, making it a favored choice in large-scale fabrication projects where speed and efficiency are critical.

When implementing gas cutting, proper technique is crucial. For optimal results, it's important to maintain a consistent distance of about 1/8 inch between the cutting tip and the workpiece. This distance ensures that the flame can effectively penetrate the material without causing excessive heat damage.

**Tips:**

- Always preheat the metal to enhance the cutting process and reduce slag formation.

- Ensure your equipment is well-maintained and calibrated for consistent flame quality to avoid uneven cuts.

- Use appropriate personal protective equipment (PPE) such as goggles and gloves to safeguard against sparks and intense heat.

| Technique | Material Type | Cutting Speed (mm/min) | Heat Affected Zone (HAZ) (mm) | Efficiency Rating |

|---|---|---|---|---|

| Oxy-Fuel Cutting | Mild Steel | 300 | 3 | High |

| Plasma Cutting | Stainless Steel | 400 | 2 | Very High |

| Laser Cutting | Aluminum | 500 | 1 | Ultra High |

| Water Jet Cutting | Composite Materials | 200 | 4 | Moderate |

| Flame Cutting | Cast Iron | 350 | 3.5 | Above Average |

Welding gas cutting techniques have significantly enhanced efficiency in metal fabrication processes, primarily through the strategic use of various gases. The most commonly utilized gases in welding include acetylene, argon, carbon dioxide, and helium. Each of these gases serves a distinct purpose: for instance, acetylene is often used for oxy-fuel welding due to its high flame temperature, while argon is essential in creating an inert atmosphere during MIG (Metal Inert Gas) welding. According to industry reports, the welding materials market, which encompasses electrodes, filler materials, and gases, is projected to reach $25 billion by 2026, driven largely by advancements in vehicle construction and other industrial applications.

Welding gas cutting techniques have significantly enhanced efficiency in metal fabrication processes, primarily through the strategic use of various gases. The most commonly utilized gases in welding include acetylene, argon, carbon dioxide, and helium. Each of these gases serves a distinct purpose: for instance, acetylene is often used for oxy-fuel welding due to its high flame temperature, while argon is essential in creating an inert atmosphere during MIG (Metal Inert Gas) welding. According to industry reports, the welding materials market, which encompasses electrodes, filler materials, and gases, is projected to reach $25 billion by 2026, driven largely by advancements in vehicle construction and other industrial applications.

Tips for selecting welding gases: When choosing the appropriate welding gas for your project, consider both the material and the specific welding technique being employed. For example, using a mixture of argon and carbon dioxide can improve weld penetration and overall quality in MIG welding. Additionally, ensuring the purity of the gas is critical; impurities can adversely affect the welding process and the final product's strength. As reported, improper gas selection can lead to defects that may reduce the lifespan of welded components, particularly in high-stakes industries like automotive manufacturing.

Integrating modern techniques such as YOLO-based image processing for defect detection in welding can further optimize quality assurance. Studies indicate that automated systems capable of recognizing irregularities can greatly enhance inspection processes, ultimately reducing material waste and improving efficiency in metal fabrication. Engaging with these technological advancements will ensure that manufacturers not only meet but exceed industry standards.

Setting up gas cutting equipment properly is crucial for achieving optimal results in metal fabrication. Begin by gathering all necessary components, including a gas cylinder, pressure regulators, hoses, and cutting torches. Ensure that the workspace is well-ventilated and free of flammable materials.

The first step involves securely connecting the pressure regulators to the gas cylinder, ensuring they are tightly fastened to prevent leaks. After this, attach the hoses to the regulators and check for any leaks using a soapy water solution. If bubbles form, tighten the connections or replace faulty equipment.

Next, set the appropriate pressure for both the oxygen and fuel gas, typically acetylene, according to the specifications of your torch and cutting requirements. Once the pressures are set, ignite the torch using a spark lighter, adjusting the flame to achieve the desired cutting profile. A neutral flame, characterized by a balanced mixture of oxygen and acetylene, is often ideal for most cutting applications. Regularly monitor the flame and adjust as necessary to maintain efficiency throughout the cutting process. With the equipment set up correctly, operators can maximize productivity and ensure high-quality cuts in metal fabrication.

When using gas cutting techniques in metal fabrication, safety should be the foremost priority. Implementing proper safety practices can significantly reduce the risk of accidents and injuries. Always ensure that the workspace is well-ventilated to avoid the accumulation of harmful gases that can result from the cutting process. Additionally, it's crucial to wear appropriate personal protective equipment (PPE), including flame-resistant clothing, gloves, goggles, and face shields, to protect against flying sparks and intense light.

Tips: Regularly check and maintain gas cutting equipment to prevent leaks and malfunctions. Ensure that hoses and connections are in good condition and securely attached. Always have a fire extinguisher readily available in your workspace as a precaution against possible fire hazards created by the gas cutting process.

In addition, establishing a clear safety protocol for your team can help promote awareness and caution. Conduct training sessions that cover the hazards associated with gas cutting techniques and the proper emergency responses in case of an incident. It is also essential to have a designated area for gas cylinder storage that complies with safety regulations to further minimize risks during metal fabrication tasks.

Gas cutting techniques in metal fabrication are pivotal for enhancing operational efficiency. By focusing on precise measurements and optimizations, manufacturers can significantly improve their productivity. Emerging metrics such as capacity utilization rate and energy efficiency play a critical role in gauging performance. Establishing a baseline for these metrics allows managers to identify areas of improvement, leading to targeted investments in technologies that enhance the gas cutting processes.

Innovations in gas cutting tools and methods contribute to reducing residual stresses and improving the overall quality of the fabricated components. This is particularly important in applications like steel I-sections, where the addition of advanced techniques can strengthen structures and enhance their longevity. As the manufacturing sector increasingly prioritizes data-driven strategies, integrating gas cutting efficiencies into broader performance metrics will support a more robust framework for measuring success in the industry. As a result, companies can better navigate the skills gap and push the boundaries of what is possible in metal fabrication.