In the realm of modern agriculture, efficiency is paramount, and the choice of equipment can make a significant impact on productivity. One such essential tool that has garnered attention among farmers is the Chaff Cutter Machine. This innovative device plays a crucial role in the preparation of livestock feed by chopping straw and fodder into manageable pieces, enhancing its digestibility and nutritional value. With an increasing demand for high-quality animal feed, the Chaff Cutter Machine stands out as a transformative solution in the livestock industry.

The optimization of feed production relies heavily on the use of the Chaff Cutter Machine, which not only saves time but also ensures consistency in feed size. As farmers seek to maximize their output while minimizing waste, the advantages of investing in a reliable chaff cutter cannot be overstated. Whether for small-scale farms or larger livestock operations, this machine is designed to cater to various needs, providing a dependable method for processing bulk agricultural residues. By implementing a Chaff Cutter Machine, farmers can enhance their operational efficiency and contribute to a more sustainable agricultural system, ultimately improving livestock health and productivity.

When considering the types of chaff cutter machines available in the market, it's essential to recognize that they come in various designs and functionalities to suit different farming needs. Manual chaff cutters, for example, are simple machines operated by hand and are typically used for small-scale farms. They are ideal for farmers who may have limited budgets or who require equipment for minimal usage. These machines generally offer basic features and are effective for cutting small quantities of fodder.

On the other hand, electric chaff cutters provide a more efficient and high-capacity option for larger farms. They operate on electricity, which allows for quicker processing of larger volumes of feed. Many electric cutters are equipped with advanced settings that allow for customizable chopping sizes, enhancing the feed quality for livestock. Additionally, there are tractor-operated chaff cutters that are designed for large-scale agricultural operations, coupling robust performance with high output efficiency. These machines often work in conjunction with other farming equipment, making them indispensable for modern farming practices focused on productivity and farm management.

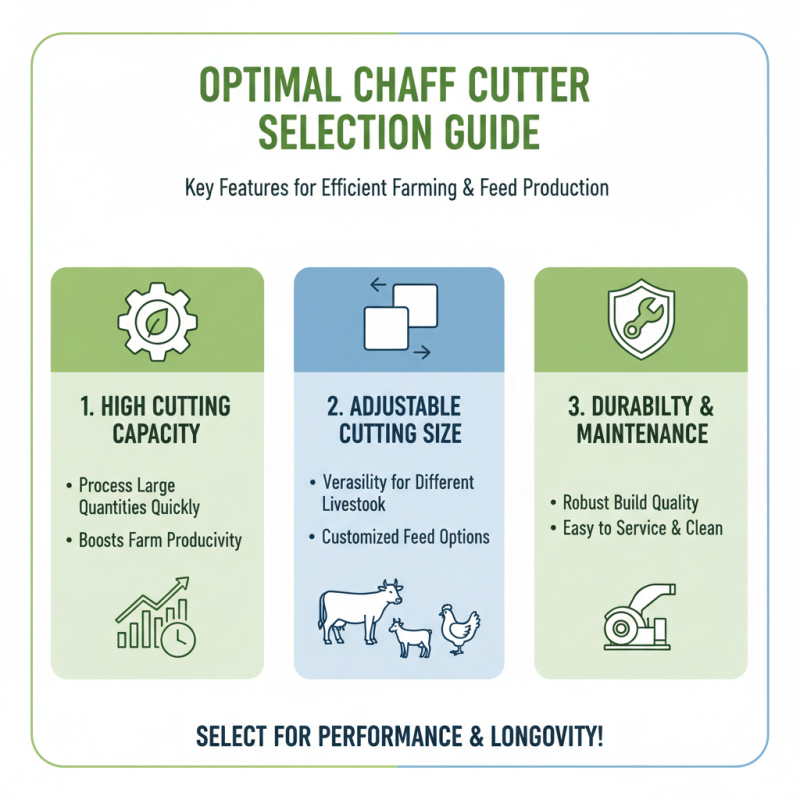

When selecting a chaff cutter machine for efficient farming and livestock feed production, several key features should be prioritized to ensure optimal performance. First, the machine’s cutting capacity is crucial. A high-capacity cutter allows for the processing of larger quantities of fodder in a shorter time, enhancing productivity on the farm. Additionally, adjustable cutting sizes can improve versatility, enabling farmers to customize the feed according to different livestock needs.

Another important feature is the durability and build quality of the chaff cutter. Machines constructed from robust materials can withstand the wear and tear of daily use, ensuring longevity and reliability. Moreover, ease of maintenance plays a vital role; a user-friendly design facilitates regular upkeep, reducing downtime and keeping operations smooth. Finally, portability and ease of operation are essential considerations that can significantly impact efficiency. A lightweight design with easy maneuverability allows for quick setup and adjustments in various farming environments. By focusing on these key features, farmers can choose a chaff cutter that effectively meets their needs for livestock feed production.

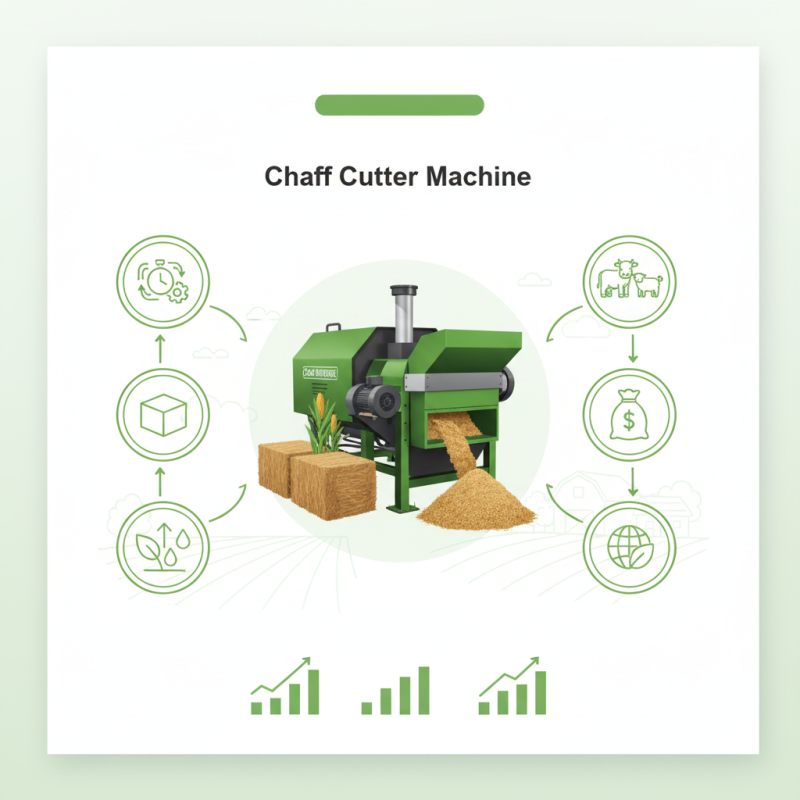

Chaff cutters have become essential tools in modern agriculture, particularly for enhancing livestock feed production. By efficiently chopping and processing straw, hay, and other fibrous crops, these machines improve the digestibility of feed, leading to better nutrient absorption in animals. According to a report from the Food and Agriculture Organization (FAO), properly processed feed can improve livestock weight gain by up to 20%, which significantly increases farm profitability. The mechanical action of chaff cutters reduces the length of feed particles, making it easier for livestock to consume and digest, ultimately resulting in healthier animals.

Moreover, the use of chaff cutters can lead to significant savings in feed costs. A study published in the Journal of Animal Science highlighted that farms employing chaff cutters saw a reduction in feed waste by more than 15%. This efficiency not only contributes to better feed management but also plays a crucial role in sustainability efforts within the farming sector. By maximizing the utility of available crop materials and minimizing waste, chaff cutters support the dual goals of economic viability and environmental stewardship in livestock production. As farmers adopt these machines, the overall productivity of livestock farming continues to improve, offering a pathway toward more efficient and responsible farming practices.

To ensure optimal performance of chaff cutter machines, regular maintenance is crucial. Begin by regularly checking the blades for sharpness and wear. Dull blades can lead to inefficient cutting and result in uneven chaff, which may affect feed quality for livestock. It’s advisable to sharpen or replace the blades as needed, following the manufacturer's guidelines.

Another essential maintenance tip is to keep the machine clean and free from any debris or leftover materials after use. Residue can accumulate and cause various operational issues, potentially leading to more significant repairs down the line. Lubrication is also vital; ensure that all moving parts are adequately greased to prevent friction and wear.

By adhering to these maintenance practices, users can extend the lifespan of their chaff cutter machines while enhancing their efficiency in producing high-quality livestock feed. Regular attention to detail in maintenance will ultimately translate to better feed production outcomes and healthier livestock.

When choosing the best chaff cutter for efficient farming and livestock feed production, it is essential to conduct a comparative analysis of various brands and models available on the market. This evaluation enables farmers to identify key features that distinguish each machine, such as cutting efficiency, durability, and ease of operation. Factors like power source—whether electric or diesel—play a significant role in determining suitability for different farming environments and scales of operation. By examining these aspects, users can assess which machines offer the best value for their specific needs.

Another critical aspect to consider is the design and construction of chaff cutters, which can influence their performance and maintenance requirements. Some models may feature advanced cutting technology that ensures finer and more uniform feed, significantly enhancing livestock health and growth. Additionally, the overall ergonomics of the machine, including its weight and portability, impact how easily it can be operated and moved, particularly in extensive agricultural settings. Evaluating these elements across different brands can help farmers make informed decisions, ultimately leading to improved productivity and cost-effectiveness in their operations.