In the world of welding, the significance of a Portable Mig Welder cannot be overstated. As one of the most versatile tools for both professionals and hobbyists, these welders provide unmatched convenience and efficiency, allowing users to tackle a variety of welding projects on the go. John Smith, a leading expert in welding technology, has remarked, "The Portable Mig Welder revolutionizes how welders approach their craft, enabling greater freedom and flexibility without sacrificing quality."

This ultimate guide is designed to navigate you through the best portable Mig welders available in 2025, focusing on essential features that cater to your specific needs. From lightweight designs to advanced technologies, we will explore how the latest developments in portable welding equipment can elevate your projects, whether you’re working on car repairs, metal art, or structural welds.

Join us as we delve into top picks and practical tips that will help you make informed decisions, ensuring that your next welding venture is not only easier but also more successful. With the right Portable Mig Welder at your side, there’s no limit to what you can achieve.

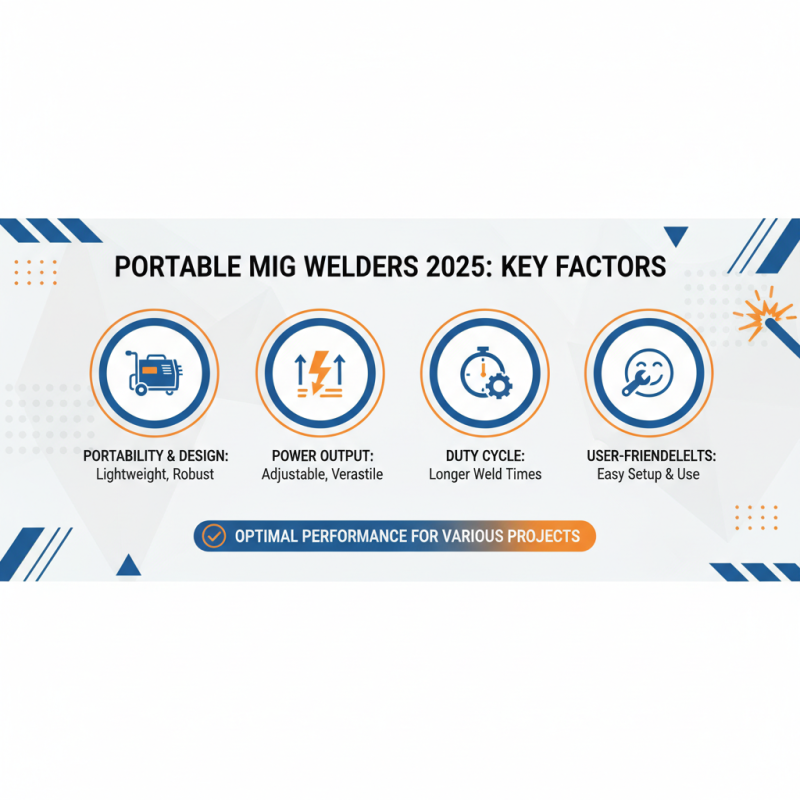

When searching for the best portable MIG welder, there are several key features to consider that can enhance both the ease of use and performance. One of the most important factors is the welder's duty cycle, which defines how long the machine can operate before needing to cool down. A higher duty cycle is essential for prolonged welding sessions, allowing you to work on bigger projects without interruptions. Furthermore, a lightweight design contributes significantly to portability, making it easier to transport the welder to various job sites or for home use.

Another essential feature is the power output. Select a welder that offers adjustable amperage settings, as this flexibility allows you to handle a wider range of materials and thicknesses. This will give you the versatility required for different tasks, from thin sheet metal to thicker sections. Additionally, consider the convenience of built-in safety features, such as thermal overload protection, which helps prevent overheating, enhancing user safety and the longevity of the machine. Lastly, check for ease of setup and user-friendly controls, as these factors can greatly impact your overall experience, especially if you are a beginner.

When considering the best portable MIG welders for 2025, it’s essential to evaluate various factors that can impact your decision. Key aspects include portability, power output, duty cycle, and user-friendliness. A lightweight design combined with a robust construction will ensure that you can easily transport the welder without compromising performance. Look for models with adjustable settings to cater to different materials and thicknesses, providing versatility for various welding applications.

To help you make an informed choice, here are some helpful tips. First, consider the amperage range of the welder. A wider range offers greater flexibility for welding different materials. Additionally, check for features like digital displays and automatic settings, which can simplify the welding process, especially for beginners. Finally, prioritize units with good customer reviews and warranty options—they can often give insights into the durability and reliability of the machine.

Lastly, maintenance is crucial. Regularly inspect your portable MIG welder for wear and tear, and keep it clean to ensure optimal performance. Familiarize yourself with the machine’s components, as understanding its functionality can help troubleshoot potential issues. By focusing on these aspects, you can confidently choose from the best portable MIG welders available, ensuring you have a quality tool for your projects in 2025.

Maintaining your portable MIG welder is crucial to ensure peak performance and longevity. According to industry reports, a well-maintained welder can enhance efficiency by up to 20%, ultimately saving time and reducing costs on projects. Regular inspections for worn-out components are essential; parts like contact tips and nozzles can wear down from regular use, leading to inconsistent weld quality. Keeping these components in good condition not only prolongs the welder's life but also ensures reliable performance, which is critical in professional settings.

Another vital aspect of maintenance involves keeping the welder clean and free from contaminants. Dust and dirt can affect the internal mechanisms and affect the welding process. It is recommended to clean the welder after each use with a soft cloth and ensure that the wire feed mechanism is lubricated according to the manufacturer’s specifications. Furthermore, storing the welder in a dry, climate-controlled environment can help prevent rust and corrosion, which are significant contributors to equipment failure. Regular maintenance not only boosts the efficiency of the welder but also aligns with findings from recent studies that suggest proactive maintenance can decrease operational downtime by more than 30%.

When utilizing a portable MIG welder, safety should always be the top priority. The American Welding Society (AWS) highlights that nearly 40% of welding accidents are attributed to inadequate personal protective equipment (PPE) and unsafe work practices. To mitigate these risks, welders must wear appropriate gear, including a welding helmet with proper face shield protection, gloves, and flame-resistant clothing. In addition, ensuring adequate ventilation in the workspace is crucial to prevent exposure to harmful fumes often generated during the welding process.

Another essential safety precaution involves understanding the proper operational techniques of a MIG welder. According to industry reports, improper handling of welding equipment can significantly increase the chances of electrical hazards. Therefore, it's imperative to inspect the welder's wiring and connections prior to use. Keeping the workspace clear of flammable materials, maintaining a safe distance from bystanders, and using a fire extinguisher nearby can also dramatically decrease the risk of fire-related incidents during welding tasks. Implementing these safety measures not only protects the welder and those around them but also enhances the quality and efficiency of the welding work performed.

This chart compares different models of portable MIG welders based on their weight, maximum output, duty cycle, and price. Choosing the right portable MIG welder involves considering these key specifications to ensure you find a model that fits your needs and budget.

When considering portable MIG welders, many users have common concerns that can inhibit their purchasing decisions. A significant point of inquiry is the power output and its relation to the welder's portability. According to industry reports, models offering a power range from 140 to 200 amps are generally considered ideal for versatility and efficiency, allowing users to handle various metals ranging from thin sheets to heavier gauge materials. As noted in a study by the American Welding Society, understanding the balance between weight and performance is crucial; lighter units under 50 pounds are often more desirable for mobile applications, while still providing sufficient power for robust tasks.

Another frequent concern revolves around the ease of use, especially for beginners. User-friendly controls and setups can significantly impact welding success and safety. The Welding Equipment Industry Association highlights that well-designed user interfaces can reduce the learning curve by up to 50%, making it easier for novices to achieve quality welds without extensive training. Additionally, questions often arise about the durability of portable welders under various working conditions. Recent data suggests that models with all-metal casings and advanced cooling mechanisms offer greater durability and improved longevity, which are essential for frequent outdoor use. Addressing these common FAQs can empower users to make informed decisions and select a portable MIG welder that fits their unique needs.

| Model | Welding Capacity | Weight | Price Range | Features |

|---|---|---|---|---|

| Model A | Up to 0.045" Steel | 30 lbs | $200 - $300 | Dual voltage, Easy setup |

| Model B | Up to 1/4" Aluminum | 40 lbs | $300 - $400 | Auto-settings, Light weight |

| Model C | Up to 3/16" Steel | 25 lbs | $150 - $250 | Compact design, Simple controls |

| Model D | Up to 1/2" Steel | 50 lbs | $400 - $500 | High duty cycle, Digital display |

| Model E | Up to 3/8" Steel | 55 lbs | $500 - $600 | Inverter tech, Heavy-duty construction |