In the world of roofing, precision is key. A cutting-edge tool that stands out is the Roof Cutter Machine. According to David Carter, a roofing expert with over twenty years of experience, “The right machine can transform how contractors work.” Efficiency and accuracy matter in this industry.

Finding the best Roof Cutter Machine can save time and reduce waste. Not all machines are created equal. Some cut quickly, while others may struggle with different materials. You need to consider what your specific needs are. Not every product on the market provides value for money.

It's essential to pay attention to the details. Look for features like blade quality, ease of use, and safety mechanisms. User reviews often highlight both pros and cons. Sometimes, a machine can promise too much. Others may not meet expectations. Always remain critical and do thorough research before making a purchase.

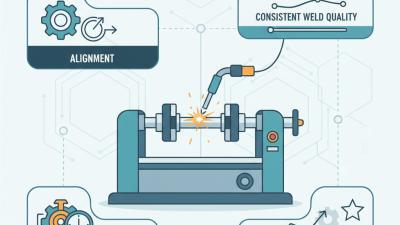

Roof cutter machines have become essential tools in the roofing industry. These machines streamline the cutting process, making it faster and more accurate. According to a report from the National Roofing Contractors Association, 79% of contractors believe that advanced equipment improves job efficiency. This efficiency is vital as roof installation can be time-consuming.

When considering roof cutter machines, it’s crucial to evaluate features like cutting precision and ease of use. Some models offer adjustable cutting angles, adding versatility for different roof types. In addition, portability is a key feature. Lightweight machines allow for easy transport and setup on job sites, which is particularly important when working in tight spaces. However, contractors should be wary of overly complex machines, as they may require additional training.

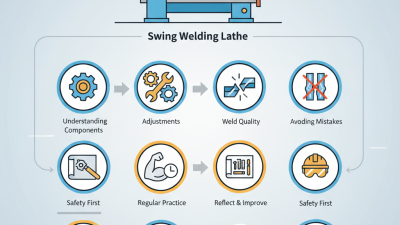

Safety is another critical concern. The Bureau of Labor Statistics indicates that injuries in roofing can be high. A machine that priorities safety features, like emergency shut-off controls, is advisable. Using a machine that is too complicated can lead to misuse or accidents. Caution is necessary; thorough knowledge of a machine's operation can prevent potential hazards. The right roof cutter machine balances efficiency with safety, ensuring that the job is done right.

When considering a roof cutter machine, certain key features stand out. Blade quality is essential. Look for blades that are durable and sharp. They ensure clean cuts through various roofing materials. A powerful motor should also be on your list. It increases efficiency and reduces cutting time. Machines with adjustable speed options allow better control for different tasks.

Weight and portability matter too. A lightweight, compact cutter is easier to handle. This can reduce fatigue, especially during long jobs. Determine if the machine is easy to transport between job sites. Ergonomic design promotes comfort in operation, which can lead to smoother results.

Tip: Always check user reviews and feedback. They can highlight potential issues or advantages of the cutter. Understanding the machine’s maintenance requirements is vital as well. Regular maintenance keeps the cutter in top shape. Lastly, ensure safety features are included. A good machine should have guards and emergency shut-off options to protect users.

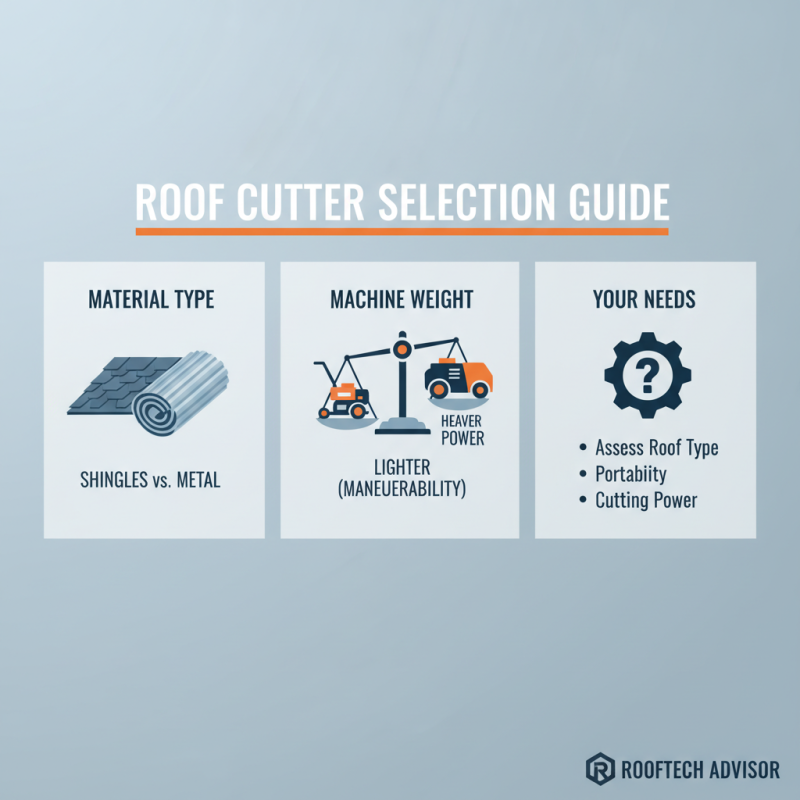

When choosing a roof cutter machine, understanding your specific needs is key. Look for a machine that suits the roofing material you work with. Some models handle shingles well, while others are designed for metal. The weight of the machine also matters. A lighter machine may offer better maneuverability, but it could lack power.

Tips: Test different machines if possible. Each one feels unique. A comfortable grip makes a significant difference during long hours. Pay attention to the blade size, as this influences cutting speed and precision.

Many users overlook safety features when buying. A machine with good safety mechanisms can prevent accidents. Ensure it has a guard that protects your hands. Remember, sometimes a higher price means better quality. Do some research before committing. Look for user reviews as they provide real-life feedback. They can guide you in making a wise investment.

When it comes to roof cutting machines, comparing brands can be quite revealing. Several reports indicate that efficiency varies greatly among different manufacturers. For instance, a 2022 industry study highlighted that some brands reported a 30% increase in cutting speed, while others lagged behind. This kind of difference can impact overall project timelines.

Another key aspect is the durability and reliability of these machines. The same study noted that up to 40% of roof cutter users experienced repeated maintenance issues with lower-ranked brands. This not only raises costs but can also lead to project delays. Users often stress the importance of choosing a machine that offers consistent performance over time.

Weight and portability are other factors in the comparison. While some machines are designed to be lightweight for easy transport, others sacrifice this benefit for additional power. This trade-off can be challenging for users who need a balance between mobility and cutting strength. Overall, understanding these differences can guide buyers to make informed decisions.

| Model | Cutting Width | Power Source | Weight | Price Range | User Rating |

|---|---|---|---|---|---|

| Model A | 14 inches | Electric | 30 lbs | $300 - $400 | 4.5/5 |

| Model B | 12 inches | Gas | 35 lbs | $450 - $550 | 4.3/5 |

| Model C | 16 inches | Electric | 28 lbs | $400 - $500 | 4.7/5 |

| Model D | 10 inches | Battery | 24 lbs | $250 - $350 | 4.2/5 |

| Model E | 18 inches | Electric | 32 lbs | $500 - $600 | 4.8/5 |

Maintaining roof cutter machines is essential for their longevity and efficiency. Regular maintenance can help avoid costly repairs. A study shows that nearly 40% of equipment failures are due to lack of proper care. It's crucial to establish a consistent maintenance schedule.

One key tip is to inspect the blades frequently. Dull blades not only hinder performance but also increase wear on the machine. Replacing worn blades can enhance cutting precision. Furthermore, cleanliness plays a vital role. Dust and debris can interfere with machine functions. Make it a habit to clean the machine after each use.

Lubrication is another aspect that should never be overlooked. Applying the right lubricant reduces friction and prolongs the machine's life. Be cautious; over-lubricating can also cause issues. A balance is necessary. Inadequate attention to these details could lead to unexpected downtime. Emphasize routine checks to ensure everything works as it should. Regularly review maintenance logs to identify any recurring issues.