When it comes to selecting the best Gold Cutting Machine for your specific requirements, the decision can be daunting due to the myriad of options available in the market. According to industry expert John Smith, a seasoned professional in the field of metalworking machinery, "Choosing the right Gold Cutting Machine is essential for achieving precision and efficiency in your projects." His insights reflect a common challenge faced by many, as the wrong choice can lead to wasted resources and unsatisfactory results.

In today’s competitive landscape, understanding the various types of Gold Cutting Machines is crucial. Factors such as cutting speed, accuracy, and ease of use can significantly impact productivity. Whether you are a jewelry maker, an industrial designer, or a hobbyist, identifying your specific needs will guide you in making an informed decision. A machine that aligns with your project demands can not only enhance your work quality but also optimize time and effort.

As you navigate through the selection process, it is important to consider not only the technical specifications but also the application for which the Gold Cutting Machine will be used. By exploring expert opinions and reviewing user experiences, you can ensure that your choice will lead to enhanced performance and satisfaction in your cutting endeavors.

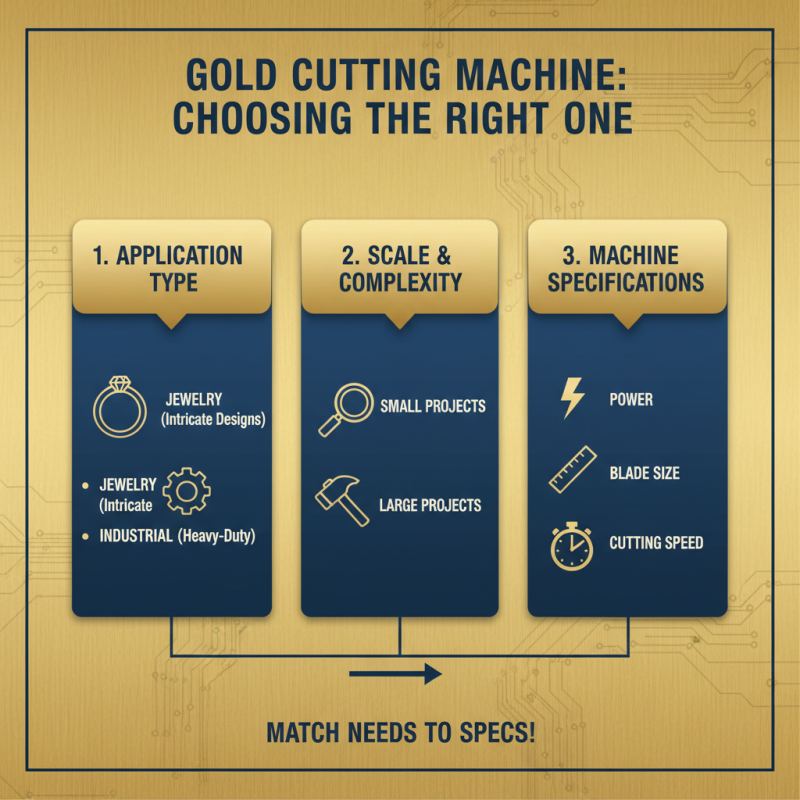

Choosing the right gold cutting machine requires a clear understanding of your specific needs and applications. First, consider the type of work you will be doing. Are you primarily focused on intricate designs for jewelry, or do you require heavy-duty cutting capabilities for larger projects? Identifying the scale and complexity of your tasks will help you determine the machine specifications that suit your requirements, such as power, blade size, and cutting speed.

Tips: Before making a purchase, assess the materials you most frequently work with. Different cutting machines are optimized for various gold alloys, and selecting a machine designed for your specific material can greatly enhance efficiency and precision. Additionally, think about the ease of use and maintenance. A user-friendly interface and straightforward maintenance routines can save you time and effort in the long run.

Furthermore, evaluate the machine's mobility and size according to your workspace. If you have limited space, a compact, portable machine might be the best choice. Conversely, if your operations are more extensive, investing in a larger, more robust model could be beneficial. Understanding these aspects will ultimately guide you in selecting a machine that meets both your current and future cutting needs.

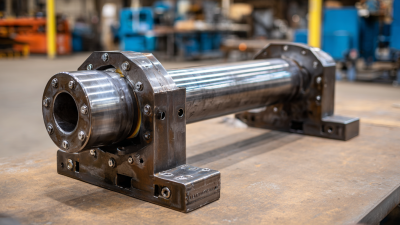

When choosing a gold cutting machine, it's essential to focus on key features that will enhance your productivity and ensure precision. First, consider the machine's cutting speed. A faster cutting speed can significantly increase efficiency, enabling you to complete projects more swiftly. Look for machines with adjustable speeds, allowing you to customize operations based on the specific requirements of your task.

Another vital aspect to consider is the type of blade used in the machine. High-quality blades can greatly affect the accuracy and quality of the cut. Ensure that the machine you choose is compatible with various blade types, which can help you achieve detailed designs and intricate cuts without compromising the integrity of the material.

Tips: Always check for a machine that offers ease of use, especially if you are new to gold cutting. User-friendly controls and clear instructions can save you time and reduce the learning curve. Additionally, investing in a machine with good safety features is crucial; you want to ensure that you are operating in a safe environment while handling valuable materials. Make sure to read reviews and seek recommendations before making a purchase to find the best fit for your needs.

When it comes to selecting the best gold cutting machine for your needs, understanding the various types of cutting technologies available is crucial. There are primarily three types of gold cutting technologies: laser cutting, water jet cutting, and plasma cutting. According to a recent industry report, laser cutting has gained significant market share, accounting for approximately 40% of the gold cutting machinery market due to its precision and efficiency. It can produce intricate designs with minimal material wastage, making it ideal for jewelers and artisans who value detail.

Water jet cutting, on the other hand, utilizes high-pressure water to slice through gold and other materials. This technique is favored when thickness variations are present or when heat-sensitive materials need to be processed, as it does not alter the material properties. However, it has a slightly lower cutting speed compared to laser technology.

Plasma cutting, while less common for gold specifically, is often utilized in industrial applications to cut thicker metals, with research indicating it can handle materials up to several inches thick with speed and efficiency.

Tips: When choosing a cutting technology, consider factors such as the thickness of the gold you intend to cut, the complexity of designs you require, and your budget constraints. Additionally, assess the maintenance needs of each machine type, as laser cutters typically necessitate more regular upkeep than water jet systems. Understanding these elements will help you make a more informed decision and find the perfect cutting solution tailored to your specific needs.

When considering the purchase of a gold cutting machine, budget plays a pivotal role in determining the right choice for your specific needs. Industry reports indicate that quality machines can range from $2,000 to over $10,000, heavily influenced by features like precision, cutting speed, and durability. For example, according to a 2022 market analysis, machines that offer advanced laser technology often fall on the higher end of the spectrum, but they provide significantly enhanced accuracy and reduced waste, making them a worthwhile investment for jewelers or manufacturers handling large volumes.

It's essential to evaluate not just the initial cost of the machine but also the long-term operating expenses. Maintenance, repair, and the cost of consumables can accumulate significantly over time. A report by the Machinery Research Institute highlights that businesses often overlook these additional costs during the purchasing process, which can lead to budget overruns. Furthermore, many models require specific training or expertise, which could incur further investment in employee education. Careful consideration of these factors will ensure that you achieve the best return on your investment while meeting your operational needs.

| Machine Type | Cutting Capacity (mm) | Power (W) | Price ($) | Recommended Use |

|---|---|---|---|---|

| Manual Cutting Machine | 5-25 | 500 | 300 | Hobbyists |

| Semi-Automatic Cutting Machine | 10-50 | 1500 | 800 | Small Businesses |

| Fully Automatic Cutting Machine | 20-100 | 3000 | 2000 | Large Enterprises |

| Laser Cutting Machine | 5-20 | 2000 | 1500 | Precision Cutting |

When investing in a gold cutting machine, proper maintenance and support play a crucial role in ensuring the longevity and optimal performance of the equipment. Regular upkeep can prevent costly repairs and extend the life of your machine, thereby maximizing your return on investment. Simple tasks, such as cleaning the cutting area and regularly checking for wear and tear, can make a significant difference in the machine’s efficiency. Additionally, consulting the manufacturer’s guidelines for maintenance schedules and recommended practices will help you stay on track and avoid potential issues.

In terms of support, it's essential to have access to reliable customer service and technical assistance. This ensures that any problems or questions regarding the machinery can be addressed promptly. Look for manufacturers that offer comprehensive support, including troubleshooting guides, online resources, and responsive customer service teams. Establishing a relationship with your supplier for ongoing support can also help you stay informed about the best practices for maintaining your gold cutting machine and adapting to any new technologies that may emerge in the industry. By prioritizing maintenance and support, you can ensure that your equipment remains in top condition, contributing to your overall productivity and success.