When it comes to welding projects, choosing the right equipment is essential. A Portable Mig Welder can be an excellent choice for both hobbyists and professionals alike. Its compact design allows for easy transport, making it ideal for various locations. With advancements in technology, these welders are more efficient and user-friendly than ever before.

However, selecting the best Portable Mig Welder requires careful consideration. You need to assess your specific project needs. Different models offer different features. Some may be better for thicker materials, while others excel in portability. It may feel overwhelming to compare all the options available.

Reflecting on your experience with welding can also help guide your decision. What have you struggled with in the past? What would make your projects easier? Sometimes, the glitzy features become distractions. Focusing on practicality will ultimately lead to better outcomes. A Portable Mig Welder should enhance your work, not complicate it.

Choosing the right portable MIG welder involves understanding different types available on the market. Typically, there are two main types: gas-shielded and gasless models. Gas-shielded welders use a shielding gas, which protects the weld from contamination. They often produce cleaner welds but require more setup and can be less portable. Gasless models, on the other hand, rely on a flux-cored wire. This simplifies the process and enhances portability, making them suitable for outdoor work.

When evaluating MIG welders, weight is crucial. Heavier units can be cumbersome. Look for options that balance power and portability. Some welders claim to be lightweight but fall short in real-world use. Battery-operated models offer tremendous convenience. However, their limited power can hinder larger projects. Take note of your typical projects when choosing a model. If you frequently work on thick metals, ensure your welder can handle it.

Also, consider the control options available. Some welders come with intricate settings, while others are simpler. A complex interface can be daunting for beginners. Yet, basic controls might limit advanced users. Reflect on your skill level before deciding. If you're new to welding, a more straightforward option could reduce frustration.

| Welder Type | Welding Process | Input Voltage | Weight | Ideal Materials | Price Range |

|---|---|---|---|---|---|

| Gas MIG Welder | MIG Welding | 120V or 240V | 40 lbs | Steel, Aluminum | $300 - $800 |

| Gasless MIG Welder | FCAW Welding | 120V | 30 lbs | Thin Steel, Sheet Metal | $200 - $600 |

| Multi-Process Welder | MIG / TIG / Stick | 120V or 240V | 50 lbs | Steel, Aluminum, Stainless Steel | $400 - $1000 |

| Inverter MIG Welder | MIG Welding | 120V or 240V | 45 lbs | All Types of Metal | $500 - $1200 |

When selecting a portable MIG welder, several key features should guide your decision. The welder's power output is crucial. It determines thickness limitations for metals. Look for models that offer adjustable settings to suit various projects. A welder with 110V and 220V capabilities adds versatility. Consider ease of use as well. Some models come with user-friendly interfaces that simplify setup for beginners. However, simplicity may come at the expense of advanced options.

Weight and portability are essential aspects. A lighter welder is easier to transport. Yet, heavier models might offer stability during use. Check the build quality too. Durability is often linked to performance longevity. But sturdy welders can be less portable. Gauge the right balance for your needs. Also, remember to examine the duty cycle. This indicates how long the welder can operate before needing a cooldown. A low duty cycle may frustrate longer projects. Reflect on your typical usage to find the perfect fit.

When assessing power and performance for your MIG welding projects, consider the material thickness you'll be working with. For thin materials, a welder with a lower output of 130 to 150 amps is often sufficient. However, for thicker materials, look for a welder that can output up to 250 amps. According to industry data, most hobbyists find that welders operating between 200-250 amps provide a good balance for diverse projects.

Voltage is another key factor. Most portable MIG welders operate on 110V or 220V. A 220V welder typically excels in performance, providing deeper penetration and faster welding speeds. Research indicates that using a 220V machine can significantly reduce welding time, making it ideal for larger jobs. However, portability may be an issue, as 110V units are often lighter and easier to transport.

Consider your experience level too. Beginners might benefit from a machine with adjustable settings and user-friendly features. Data shows that welders with intuitive settings lead to better outcomes for novices. Yet, these might limit advanced users. Knowing your skill level and project requirements can help you choose wisely. Ultimately, choose a welder that fits your specific needs while keeping in mind the learning curve and adjustments required along the way.

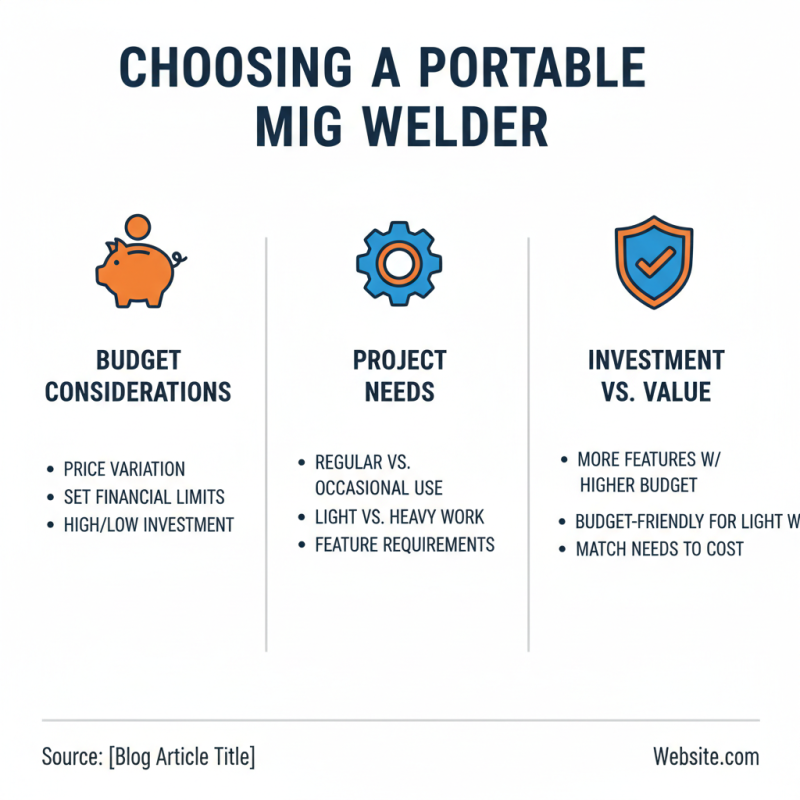

When choosing a portable MIG welder, budget plays a crucial role. Prices can vary significantly, and understanding your financial limits is essential. Consider your project needs. Will you use it regularly or just occasionally? A higher investment may offer better features. However, a budget-friendly option might suffice for light work.

Remember to factor in additional costs. Accessories like gas and protective gear can add up. Researching your options is vital. Look at reviews and experiences from other users. Sometimes, lower-priced welders may come with hidden issues. Reflect on what you truly need versus what sounds appealing.

It’s also wise to think long-term. A more expensive welder could save you money over time if it lasts longer or requires fewer repairs. But don’t rush the decision. Take time to evaluate various models within your budget. This process is just as important as the price tag. A hasty choice can lead to regrets later. Your goal should be to strike a balance, ensuring you get value without overspending.

When using a portable MIG welder, safety is paramount. According to the American Welding Society, over 50% of welding accidents involve inadequate safety practices. Wearing proper gear is essential. A welding helmet protects eyes from harmful UV rays. Gloves should be durable, providing both heat resistance and grip. Additionally, a fire extinguisher should always be nearby, ready for emergencies.

Regular maintenance extends the life of your welder. Industry reports suggest that 30% of equipment failures are due to neglect. Ensure the machine is clean and free from dust buildup. Check all hoses for leaks and replace any worn-out components. The consumables, such as tips and nozzles, should be inspected frequently. Even a small blockage can lead to poor welding quality. Take time to assess and reflect on those maintenance tasks.

Small efforts in care can go a long way.