Choosing the right Roof Cutter Machine can be a daunting task. With numerous options available, it can feel overwhelming. Industry expert, John Smith, once said, “Selecting the best machine requires careful consideration of your specific needs.” His insights underline the importance of understanding your requirements before making a purchase.

When evaluating Roof Cutter Machines, think about your project's scale. Is it a small renovation or a large commercial job? Each machine has unique features tailored to different applications. For example, some machines are built for efficiency, while others focus on precision. Familiarizing yourself with these differences can lead to better choices.

It’s also vital to consider the machine's ease of use. A complicated setup can lead to frustration and wasted time. Investing in a user-friendly model can enhance your workflow. However, not all machines are perfect. A popular model may have limitations in durability. Reflection on these aspects will guide you in selecting the best Roof Cutter Machine for your needs.

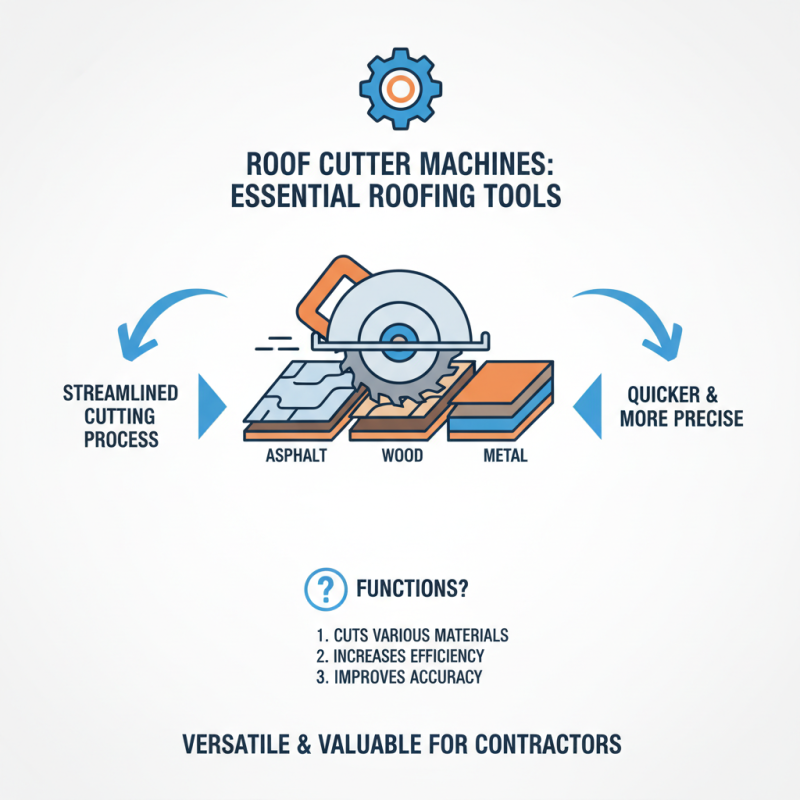

Roof cutter machines are essential tools for efficient roofing work. They streamline the cutting process, making it quicker and more precise. Understanding their functions is crucial before making a purchase. These machines can handle a variety of materials, including asphalt, wood, and metal. This versatility makes them appealing to many contractors.

Tips: Consider the machine's weight and portability. A heavier model may be more stable but harder to move. Look for a machine that offers adjustable cutting depth. This feature allows for flexibility in various projects, especially when dealing with different roofing materials.

It's important to recognize that not all machines are created equal. Some may perform exceptionally well but are complicated to operate. Training may be needed, leading to potential downtime on job sites. Assessing the ease of use should be a priority. Be aware of maintenance requirements too. Some machines require more upkeep than others, increasing long-term costs. Always think critically about how often you'll use the machine. Investing in a high-quality option could save money over time.

When selecting a roof cutter machine, key features are essential. Focus on the blade size. A larger blade may cut through thick materials efficiently. However, it can be cumbersome for intricate work. Consider the balance between power and precision.

Next, examine the machine’s weight. A lightweight model is easier to maneuver on rooftops. Yet, heavier machines often provide stability. You might find yourself often choosing between convenience and stability. The cutting depth is another crucial factor. Ensure that the machine can handle the thickness of your roofing materials.

Finally, think about safety features. A machine with adequate safety guards is vital. Accidents can happen, even with the most experienced operators. Don’t overlook maintenance requirements. A machine that is difficult to maintain can cause frustration over time. Reflect on these aspects before making a choice. Your long-term efficiency depends on it.

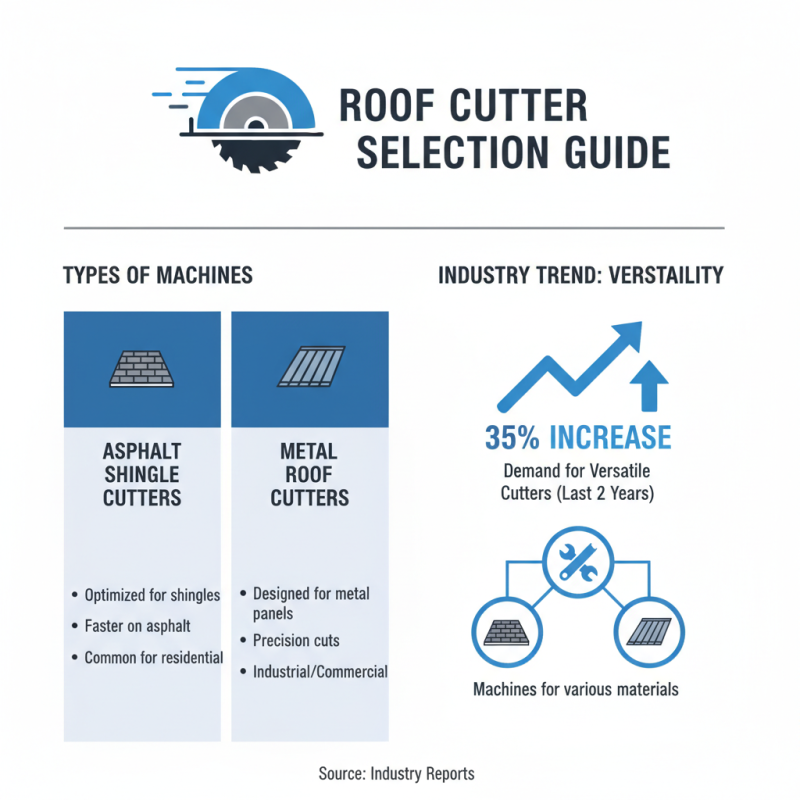

When selecting a roof cutter machine, comparing different types is essential. Some machines are designed for asphalt shingles, while others excel with metal roofs. According to industry reports, the demand for versatile cutter machines has risen by 35% over the last two years. This trend highlights the need for machines that can handle various roofing materials efficiently.

Manual cutter machines often require physical strength and skill. They can be less costly but may lead to fatigue. Conversely, powered machines are easier to operate and save time. However, many users report that initial costs can be substantial. Additionally, maintaining a powered machine might require specialized knowledge, which can be a hurdle for some.

Choosing the right machine involves understanding your specific requirements. For instance, a contractor working primarily with asphalt might not need a complex setup that can handle specialty cuts for metal roofs. It's crucial to evaluate the types of jobs you undertake. The wrong choice could lead to inefficiencies and even project delays. Reflecting on past experiences with equipment can guide future purchases and enhance productivity.

When choosing a roof cutter machine, it's crucial to assess your specific cutting needs. Different roofs require different approaches. A flat roof may need a different blade than a sloped one. Understanding the material is key. Statistics show that approximately 40% of roofing projects involve cutting through materials like asphalt or metal. Each material has unique thicknesses and strengths.

Consider the project scale. Are you working on a small residential task or a large commercial building? Industry data reveals that 25% of contractors underestimate their cutting needs. This often leads to purchasing machines that are either too powerful or not robust enough. Analyze the frequency of usage. For frequent projects, investing in a durable and efficient machine can save time and money.

Don't overlook weight and portability. A machine that’s too heavy might be challenging to maneuver on-site. In fact, over 10% of operators report delays due to equipment that is difficult to transport. Think about your team's competence. A highly skilled crew may perform efficiently with a basic model, while less experienced workers might need something more user-friendly.

| Feature | Description | Importance Level | Recommended Options |

|---|---|---|---|

| Cutting Power | Measured in amps or watts, indicates the ability to cut through different materials. | High | Electric (1500W+), Gas-powered (above 5HP) |

| Blade Size | Larger blades can cut through thicker materials more efficiently. | Medium | 12-inch, 14-inch options |

| Weight | The weight affects portability and ease of handling. | Medium | Lightweight (<30 lbs), Heavy-duty (30+ lbs) |

| Adjustable Angle | Allows for more versatile cutting, especially on angled roofs. | High | Models with tilt adjustments |

| Safety Features | Includes blade guards, emergency stops, and safety interlocks. | High | Features like kickback protection |

| Warranty | Indicates the manufacturer's confidence in their product. | Medium | 2-year or more recommended |

When considering a roof cutter machine, budgeting is crucial. Start by determining how much you can afford. Roof cutter machines can vary widely in price. High-quality options may seem appealing but could strain your finances. Look for value, not just the lowest price.

Factor in maintenance costs as well. Some machines require more upkeep than others. Hidden costs can impact your budget significantly. You might also need accessories or additional tools that add to the overall expense. Try to estimate these additional costs upfront.

Reflecting on past purchases can help shape your decision. Did you invest too much in features you never used? It’s essential to focus on your specific requirements. A less expensive machine may suffice if your needs are modest. Balance quality with your budget. Make informed choices based on real needs and potential future growth. Awareness of your financial limits can lead to better, more sustainable decisions.