Choosing the right Portable Mig Welder can significantly influence the quality and efficiency of your welding projects. According to recent industry reports, the global welding equipment market is projected to reach approximately $23 billion by 2025, driven by innovations in portable welding technology that cater to both professionals and hobbyists.

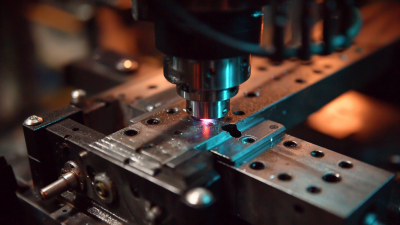

Portable Mig Welders, known for their versatility and ease of use, have seen a notable increase in demand, particularly in sectors such as construction and automotive repair. With the ability to deliver high-quality welds in a compact form, understanding the features that define an effective portable welder is crucial for optimizing performance and meeting specific project requirements. By selecting a machine that aligns with your unique welding needs, you can not only enhance the outcomes of your endeavors but also ensure the longevity and reliability of your equipment.

Portable Mig Welders, known for their versatility and ease of use, have seen a notable increase in demand, particularly in sectors such as construction and automotive repair. With the ability to deliver high-quality welds in a compact form, understanding the features that define an effective portable welder is crucial for optimizing performance and meeting specific project requirements. By selecting a machine that aligns with your unique welding needs, you can not only enhance the outcomes of your endeavors but also ensure the longevity and reliability of your equipment.

When selecting a portable MIG welder, several key factors should be considered to ensure it meets your welding needs. First, evaluate the welder's power output, typically measured in amperage. A higher amperage rating allows for welding thicker materials, while a lower output is suitable for thinner sheets. Choosing a machine with adjustable settings enables versatility across various projects, accommodating different materials and thicknesses.

Another important consideration is the welder’s weight and portability. Look for a lightweight design with a sturdy handle for easy transportation. Also, examine the power source; some MIG welders require a dedicated power outlet, while others operate on standard household electricity. Finally, assess the availability of replacement parts and customer support, as this can impact the longevity and maintenance of your equipment.

Prioritizing these factors will help you select a portable MIG welder that aligns with your specific welding tasks and preferences.

When selecting a portable MIG welder, understanding the various features and specifications is crucial for tailoring the equipment to your specific needs. One of the primary considerations is the output power, usually measured in amperage. Higher amperage allows for welding thicker materials, but if your projects involve lighter materials, a lower amperage might suffice. Additionally, many MIG welders offer settings for voltage, which can impact penetration and the overall weld quality.

Another significant aspect to consider is the duty cycle, which refers to the amount of time the welder can operate before it needs to cool down. A welder with a higher duty cycle allows for prolonged use, making it suitable for larger projects. Portability is also influenced by the weight and design features, such as a handle or built-in wheels, which can make transporting the welder easier. Lastly, features like spool gun compatibility, gas options, and wire feed speed adjustments can enhance the versatility and performance of the welder, enabling you to handle a wider variety of welding tasks efficiently.

| Feature | Description | Importance |

|---|---|---|

| Welding Capacity | The maximum thickness of metal that can be welded. | High |

| Power Range | Input voltage and current settings available. | High |

| Portability | Weight and design for easy transport. | Medium |

| Duty Cycle | Amount of time the welder can run before needing a cooldown. | High |

| Wire Feed Speed | Speed at which the welding wire is fed into the gun. | Medium |

| Controls | Type of controls (manual vs digital) for settings adjustment. | Medium |

| Safety Features | Features that protect against hazards (overheating, short circuits). | High |

| Warranty | Duration and coverage of warranty provided. | Medium |

When selecting a portable MIG welder, assessing your welding projects is vital to determine the required power output. Start by considering the materials you will be working with; softer metals like aluminum or thin sheets might not need as much power as thicker steel. Understanding the thickness of the materials can help you choose a welder that offers the right output range, typically measured in amps. A welder with adjustable settings will provide the flexibility needed for various projects.

Moreover, the nature of your projects—whether you're doing hobbyist work or professional fabrication—will influence your choice. For light-duty tasks, a welder with a lower power output (around 130-180 amps) may suffice, while heavier industrial applications may require a machine with a higher capacity (over 200 amps). Additionally, consider the welder's duty cycle, which indicates how long it can operate continuously before needing a cool-down. Matching the power output and duty cycle to your specific welding requirements ensures you select a portable MIG welder that can handle the demands of your projects effectively.

When selecting the right portable MIG welder for your needs, one critical aspect to consider is brand quality and warranty options. A welder's performance and longevity often correlate with the manufacturer's reputation.

Established brands tend to offer better durability and support, ensuring that you have access to parts and service when needed. It’s important to research various brands and read customer reviews to assess their quality over time.

Tips: Look for manufacturers that provide comprehensive warranty options. A good warranty often indicates a company’s confidence in its product. A three-year warranty or longer is typically a sign of a reliable welder that’s built to last. Additionally, consider brands that offer responsive customer service, as this can immensely enhance your experience, especially if you encounter issues with your welder.

Another factor to examine is the materials used in the welder's construction. High-quality materials usually translate to better performance and longer lifespan. Choosing a welder that incorporates robust components will save you money in repairs and replacements in the long run. Prioritizing both brand reputation and warranty options can ensure that you find a portable MIG welder that meets your needs effectively and endures through your projects.

When budgeting for a portable MIG welder, it's essential to consider not just the initial cost, but also the features and capabilities that will meet your specific welding needs. For those new to welding, models that offer versatility—such as the ability to switch between MIG and flux-core welding—can be particularly advantageous. Hands-on tests have highlighted that certain brands perform exceptionally well, making them popular choices among first-time users. This versatility often comes at various price points, allowing you to choose a welder that fits your financial plan without compromising performance.

Additionally, evaluating the specifications of portable MIG welders is crucial. For instance, many budget-friendly options operate on 110V, making them accessible for home workshops without requiring extensive electrical modifications. Reports indicate that these models maintain a balance between affordability and necessary functionalities for various welding tasks. By focusing on well-reviewed options that have been tested in real-world scenarios, you can find a suitable welder that not only meets your technical requirements but also aligns with your budgetary constraints.