In the world of welding, the right equipment can make a significant difference in both efficiency and quality of the final product. The "Swing Weld Carriage" is an essential tool that many professionals rely on to ensure precise welds, especially in challenging positions and applications. According to John Smith, a respected expert in welding technology, "Choosing the right Swing Weld Carriage can transform your project, making it not only easier but also enhancing the overall quality of your welds.”

When selecting a Swing Weld Carriage for your welding needs, several factors must be considered, including the size and type of the workpiece, the welding technique employed, and the specific environment in which you will be operating. Understanding these elements will guide you in making an informed decision that aligns with your project requirements.

Moreover, the selection process can often feel overwhelming due to the variety of options available in the market. However, by prioritizing key features such as mobility, stability, and compatibility with your welding equipment, you can ensure that your chosen Swing Weld Carriage will meet your expectations and facilitate an efficient welding process. Whether you are taking on a large industrial project or smaller fabrications, the right equipment is crucial for achieving optimal results.

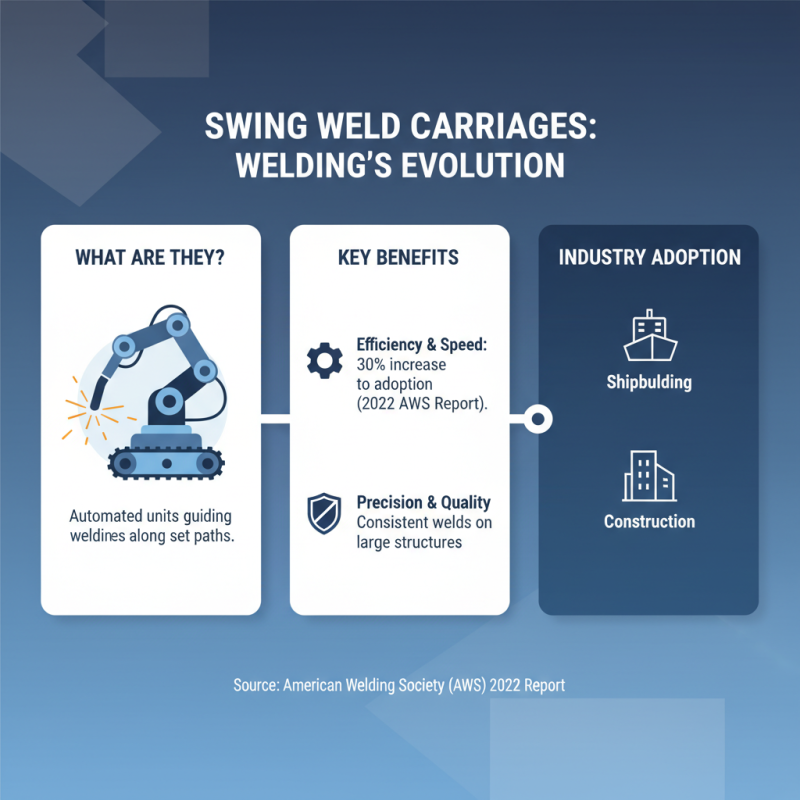

Swing weld carriages have become essential tools in the welding industry, providing versatility and efficiency for various welding applications. These automated units are designed to carry the welding torch along a predefined path, allowing welders to achieve consistent and precise welds, particularly on large structural components. According to a 2022 report by the American Welding Society (AWS), the adoption of automated welding processes, including swing weld carriages, has increased by over 30% in sectors such as shipbuilding and construction, where operational efficiency and quality are paramount.

Understanding the applications of swing weld carriages is critical for selecting the right equipment for specific projects. These carriages are particularly useful in longitudinal welding tasks, such as those found in fabricating pipelines or large steel beams, where maintaining a steady, uniform speed and arc length is crucial. Data from the International Institute of Welding (IIW) indicates that using automated solutions like swing weld carriages can enhance productivity by up to 50%, reduce the likelihood of human error, and improve weld integrity. Moreover, the technological advancements in these carriages have integrated features such as programmable settings and real-time monitoring, allowing for adjustments based on the material type and thickness, making them adaptable tools for a wide range of welding scenarios.

When selecting a swing weld carriage for your welding projects, the first key feature to consider is its weight capacity. Ensure that the carriage can handle the maximum weight of the welding equipment you'll be using, along with any additional materials. A carriage designed for higher weight loads will offer better stability and durability, preventing any risk of tipping or failures during operation. Additionally, look for adjustable features that can accommodate different welding setups, enhancing versatility for various applications.

Another important factor is the speed and travel range of the swing weld carriage. Choose a model that allows for variable speed settings, enabling efficient and precise welding movement across different types of joints. Moreover, consider the travel range; a carriage that offers a broader range allows for more extensive work areas and greater flexibility in positioning. Lastly, assess the ease of setup and portability. A user-friendly design with quick assembly features ensures that you can transition smoothly between projects without considerable downtime.

When selecting a swing weld carriage for your welding projects, evaluating the size and capacity is paramount. The first consideration should be the dimensions of the workpiece you'll be welding. A carriage that is too small may struggle to adequately accommodate larger materials, while an oversized unit can be cumbersome and inefficient for smaller jobs. Understanding the maximum width and length the carriage can support is essential to ensure a proper fit for your specific welding tasks, thereby enhancing productivity and ensuring safety.

In addition to size, the load capacity of the swing weld carriage significantly impacts its performance. Each welding project can vary greatly in terms of weight and material type, be it steel, aluminum, or other metals. It is crucial to choose a carriage that can handle not only the current project weight but also any future enhancements you may consider. Carriages with a higher weight capacity provide greater versatility, allowing for a wider range of operations and projects without compromising on stability or performance. Investing time in assessing these factors will aid in making an informed decision that aligns with your welding needs.

When selecting a swing weld carriage for your welding projects, it's essential to compare various models and brands to ensure you make an informed decision. Different swing weld carriages offer unique features that can significantly impact the efficiency and quality of your welding tasks. Some models might emphasize portability with lightweight designs, while others prioritize stability and consistent feed rates. Investigating the weight capacity of each model and the range of movement they provide is crucial, as these factors will dictate the situations in which each carriage excels.

Additionally, consider the technological advancements integrated into modern swing weld carriages. Some may incorporate digital controls for improved precision, while others might offer manual adjustments for better user flexibility. It's also advisable to check customer reviews and expert opinions to gather insights about the longevity and reliability of the carriages in question. By assessing these various attributes across different models and brands, you can better determine which swing weld carriage aligns best with your specific welding requirements, ultimately enhancing the productivity and quality of your output.

Maintaining a swing weld carriage is crucial for ensuring longevity and optimal performance in various welding projects. Regular upkeep not only extends the lifespan of the equipment but also contributes to the quality of welds produced. According to industry reports, properly maintained welding equipment can last up to 30% longer than poorly maintained units. To capitalize on this benefit, it's essential to adopt a systematic maintenance routine.

One primary tip for care is to regularly inspect and clean the carriage's components, including the rails and wheels. Debris accumulation can lead to friction, affecting both movement and precision. It’s advisable to use a soft cloth and a mild cleaning solution to gently wipe down the surfaces. Furthermore, lubricating bearings and moving parts at least once every three months can reduce wear and tear, ensuring smooth operation.

Another crucial aspect of maintenance is monitoring the electrical and safety components of the weld carriage. Conducting checks on the power supply and connections periodically helps prevent unexpected failures during operation. Additionally, inspecting the emergency stops and limits switches regularly can enhance safety and performance. Data from industry studies indicate that preventive maintenance yields a 20% reduction in unforeseen operational issues, ultimately leading to increased productivity on welding projects.