The Swing Weld Carriage is an indispensable tool for modern welding projects. This device simplifies the welding process, allowing for precise and consistent results. Whether you're working on structural steel or intricate designs, a Swing Weld Carriage can elevate your work quality.

Using the Swing Weld Carriage requires practice. Understanding the settings can be challenging for beginners. It’s essential to familiarize yourself with its features. Adjustments must be made for different materials and thicknesses. Take the time to experiment with various speeds and angles. Mistakes can happen, but they are learning opportunities.

Investing time in mastering this equipment pays off. The efficiency achieved with a Swing Weld Carriage enhances productivity. However, remember that not every project will go smoothly. Reflect on the challenges faced and seek advice from experienced welders. Continuous improvement is key to becoming proficient in welding.

The swing weld carriage is a unique tool in modern welding. It offers versatility and efficiency for different welding tasks. Using this device can help in achieving precise welds in various positions. Industry reports reveal that using a swing weld carriage can enhance productivity by 30%. This increase stems from its ability to maintain consistency and reduce manual labor.

Understanding its functionality is crucial. The swing weld carriage allows the welder to achieve a uniform bead throughout the project. The carriage moves smoothly along the workpiece, accommodating various angles and positions. This adaptability is essential for complex structures. However, improper setup can lead to misalignment and wasted materials. Regular calibration helps maintain accurate performance.

Tips for using a swing weld carriage effectively include ensuring a clean work surface. Dirt and debris can affect the weld quality. Additionally, practice using the controls before starting a major project. Familiarity with the equipment enhances confidence and precision. Remember to monitor the welding arc closely. Small adjustments can significantly impact the final result.

A swing weld carriage brings significant advantages to industrial welding projects. This tool enhances precision and consistency in welds, reducing human error. It can easily maneuver along complex joints and surfaces. The design allows for better visibility of the welding area. Proper alignment is key to achieving strong welds. With the right setup, you can create cleaner and more uniform welds.

One of the standout benefits is efficiency. Using a swing weld carriage can dramatically reduce welding time. Workers can focus more on control rather than physical strain. However, training is essential. Operators must understand adjustments and settings. If not, performance could drop, leading to rework. It’s essential to regularly inspect the equipment to maintain its effectiveness.

Another critical aspect to consider is the workspace. The swing weld carriage requires sufficient room to operate. Constrained areas may limit its full potential. Assessing the environment before use is vital. This tool can enhance productivity, yet it requires thoughtful integration. A balance of speed and quality must be achieved for the best results.

Setting up a swing weld carriage can significantly improve your welding projects. A well-configured carriage allows for consistent and precise welding, which leads to better results. According to industry reports, efficient weld carriage setups can enhance productivity by up to 30%. This is crucial in fast-paced environments, where time is money.

To begin, assess the workspace carefully. Ensure ample room for the swing weld carriage's movement. Proper alignment with the workpiece is essential. Misalignments can lead to poor-quality welds and material waste. A study notes that one misaligned weld can increase overall costs by up to 15% due to rework. Use a leveling tool to confirm your setup's accuracy.

Next, adjust the speed settings based on the material thickness and type. Each material reacts differently to heat, and improper settings can cause warping or weak joints. Data suggests that over 40% of welding defects stem from incorrect parameters. Sometimes, experimentation with settings is necessary. Take the time to analyze the results for optimal performance. Remember, it’s about finding the right balance for your specific projects.

| Step Number | Action | Tool/Material Needed | Expected Outcome |

|---|---|---|---|

| 1 | Select the appropriate weld carriage | Swing weld carriage | Efficient welding setup |

| 2 | Ensure proper alignment | Measuring tools | Accurate weld placement |

| 3 | Set travel speed | Variable speed controller | Consistent weld quality |

| 4 | Adjust welding parameters | Welding machine settings | Optimal weld penetration |

| 5 | Begin welding process | Personal protective equipment | Safe and effective welding |

| 6 | Monitor weld quality | Quality inspection tools | High-quality final product |

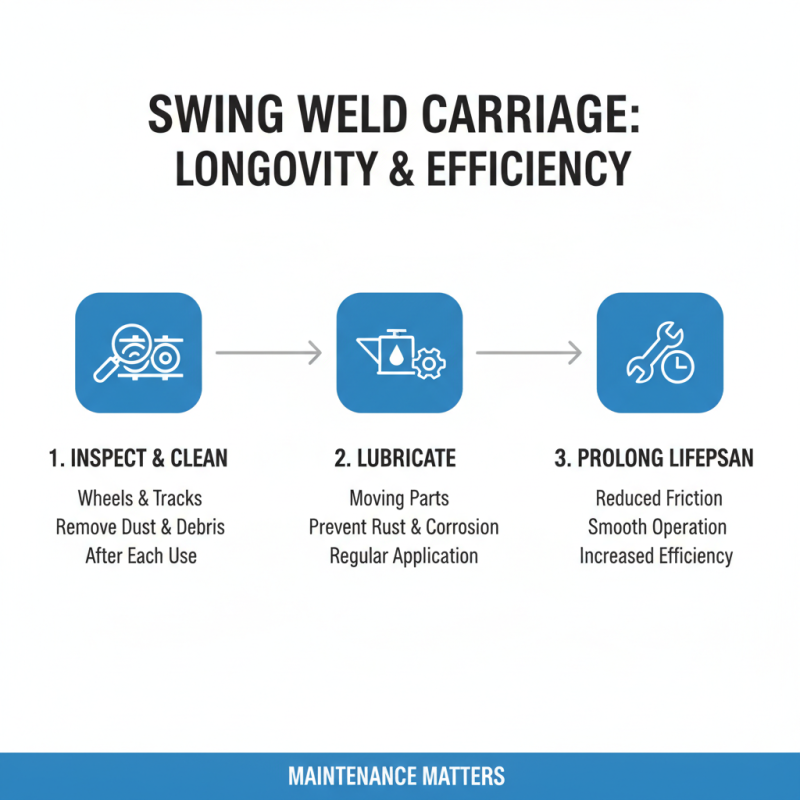

Maintaining a swing weld carriage is crucial for ensuring its longevity and efficiency. Regularly inspect the wheels and tracks for wear. Dust and debris can accumulate, causing unnecessary friction. Cleaning these parts after each use can significantly prolong their lifespan. Lubrication is equally important. Apply a suitable lubricant on the moving parts to prevent rust and corrosion.

Proper storage also plays a vital role. Always store the carriage in a dry, clean area. Avoid leaving it outside, as exposure to moisture can lead to damage. Sometimes, we forget the basics and leave tools in unsuitable places. This can lead to costly repairs. Checking for loose bolts or screws periodically is essential. Tightening them can keep everything functioning smoothly.

Lastly, training for users can minimize misuse. Over time, improper handling can lead to malfunctions. Regular refreshers on best practices can help. It’s easy to overlook this aspect but investing some time in training can yield significant returns. If you notice any unusual sounds or movements during operations, stop immediately. Ignoring these signs can lead to more severe issues down the line. Taking these maintenance steps seriously can help you get the most out of your welding projects.

When operating a swing weld carriage, safety should be a top priority. According to the Occupational Safety and Health Administration (OSHA), approximately 15% of welding-related injuries stem from equipment misuse. Before starting, ensure proper training for all operators. The carriage's movement should be smooth, minimizing the risk of accidents. Keep a clear workspace to avoid tripping hazards.

Checking the equipment before use is crucial. Inspecting cables and welds can prevent injuries. Regular maintenance is essential. A report from the American Welding Society indicates that improper equipment condition increases accident risk by nearly 30%. Personal protective equipment, like gloves and masks, should always be worn. Don't overlook the small details; they can save lives. Always be aware of your surroundings and any potential electrical hazards.

Awareness is key. Safety protocols could be forgotten in the heat of the moment. Staying vigilant can prevent accidents. Ensure that everyone on-site knows the emergency procedures. Communication can be the difference between a safe project and a hazardous situation. Operators should feel comfortable speaking up about unsafe practices or concerns. Safety is a collective responsibility, and fostering an open environment is essential.