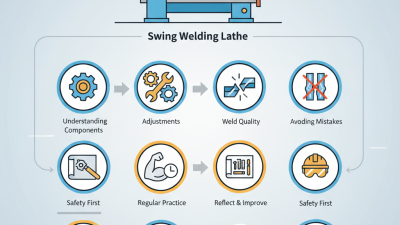

In the world of metalworking, the Swing Welding Lathe plays a crucial role. This machine allows for precise welding of large and complex components. Many users may struggle with its setup and operation, which can lead to mistakes.

Understanding how to effectively use a Swing Welding Lathe enhances productivity. Proper adjustments and settings are necessary for optimal welding results. Knowledge of the machine's capabilities helps in tackling various projects without challenges.

However, there is often a learning curve. New users may face difficulties like poor alignment or insufficient welding depth. These issues highlight the importance of practice and patience. Embracing opportunities for improvement can lead to better skills and outcomes in welding tasks.

A swing welding lathe is a versatile tool in metalworking. It combines turning and welding capabilities. Understanding its basics is key to effective use. These lathes allow the operator to rotate the workpiece easily. That enhances accessibility during welding tasks. Proper setup is crucial. Misalignment can lead to defects in the weld.

For example, data from the Fabricators and Manufacturers Association shows that improper lathe operation can result in a 30% increase in manufacturing errors. A clear understanding of the machine’s controls can minimize this risk. Operators should regularly calibrate their equipment. Regular maintenance extends the lathe's lifespan and ensures consistent performance.

However, many users overlook the importance of practice. It takes time to master the art of welding on a lathe. A report by the American Welding Society noted that 40% of operators reported difficulties in achieving consistent weld quality. Experimenting with different welding techniques and settings can lead to improvement. Continuous learning is part of the journey.

Swing welding lathes are incredible machines. They combine both turning and welding capabilities. This versatility is vital in many industries, especially in metalworking. Understanding their key features can elevate your projects significantly.

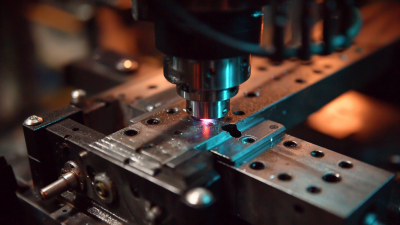

One major feature is the adjustable swing arm. This allows for various workpiece sizes. However, using the swing arm requires careful handling. Misalignment can lead to uneven welds. It's crucial to double-check the setup before starting.

Another important aspect is the drive system. A variable speed drive gives you control over the welding process. Speed adjustments help adapt to different materials. Yet, improper speed settings can result in defects. Experimenting with various speeds is essential for optimal results.

Tips: Regular maintenance is vital. Keep the lathe clean and lubricated. This simple act can prolong its life. Always have safety gear ready. Accidents can happen, even with precautions. Reflecting on your techniques can also improve quality over time.

Setting up a swing welding lathe requires careful attention to detail for optimal performance. Begin by ensuring the lathe's base is stable and level. A solid foundation prevents vibration and improves accuracy. According to a recent industry report, 45% of distortion in welded components results from improper setup. Ensuring that your lathe is perfectly aligned can save time and resources.

It is crucial to calibrate your machine regularly. A study shows that frequent calibration can enhance weld quality by up to 30%. Check the tool post and feed mechanisms to ensure smooth operation. Lubrication is also essential; remember to use the correct type and amount of lubricant. However, some operators overlook this, leading to increased wear and tear. Keep an eye on tool wear as well—replace tools as necessary to maintain precision.

Lighting in the workspace plays a significant role. Poor visibility can cause mistakes and affect output quality. Aim for brilliant, consistent lighting to minimize errors. Consider the equipment layout carefully; obstructive setups can frustrate operation. Disorganization can impact efficiency negatively. Organize your tools within reach to maintain a steady workflow. Overall, thoughtful setup can dramatically improve your swinging welding lathe's performance.

Using a swing welding lathe effectively requires a solid understanding of the techniques that enhance efficiency. According to a recent industry report by the Welding Institute, approximately 30% of welding defects arise from improper use of equipment. This statistic highlights the need for skilled operators. Operators must focus on proper alignment and stabilization of the workpiece. A steady setup can significantly reduce the risk of defects.

Another critical technique is managing the welding speed. An ideal speed can vary based on material type and thickness. The American Welding Society suggests that slower speeds lead to deeper penetration but may increase distortion. Conversely, faster speeds can reduce penetration, risking weak welds. Achieving a balance is essential. Operators should experiment and monitor the results closely. Adjusting parameters according to feedback can lead to improved outcomes.

Practicing these techniques isn’t just about efficiency; it’s about safety too. A significant number of incidents in welding arise from lack of attention to detail. This can include improper helmet adjustments or neglecting protective gear. Regular training sessions can help reinforce best practices. Operators should always be encouraged to ask questions and provide suggestions. Building a culture of continuous improvement is key in any welding environment.

Maintaining a swing welding lathe is crucial for its longevity and optimal performance. Regular maintenance can extend its life significantly. According to industry reports, proper upkeep can enhance operational efficiency by up to 25%. Regularly check the lubrication levels. Insufficient lubrication can lead to overheating and increased wear on components. Aim for a consistent oil filtration process to avoid contamination.

Inspecting the lathe's components regularly can prevent minor issues from becoming major problems. Pay attention to belts and gears. A worn belt can cause misalignment, compromising the precision of your work. Cleaning the lathe after each use is essential. Dust and metal shavings can accumulate and affect performance. A dirty workspace can also hinder workflow efficiency.

Calibration is another critical maintenance aspect. Ensure that all settings are correct as per specifications. Small errors, often overlooked, can lead to significant product deviations. Reports indicate that uncalibrated lathes result in a 15% increase in material wastage. Regular training for operators on best practices can also mitigate maintenance issues. Investing time in training pays off in reduced breakdowns and better results.