In the world of precision metalwork, the "Swing Welding Lathe" stands out as an essential tool. According to David Miller, a noted expert in metalworking, "Using a Swing Welding Lathe effectively can elevate the quality of your projects." His insights highlight its importance and versatility in the industry.

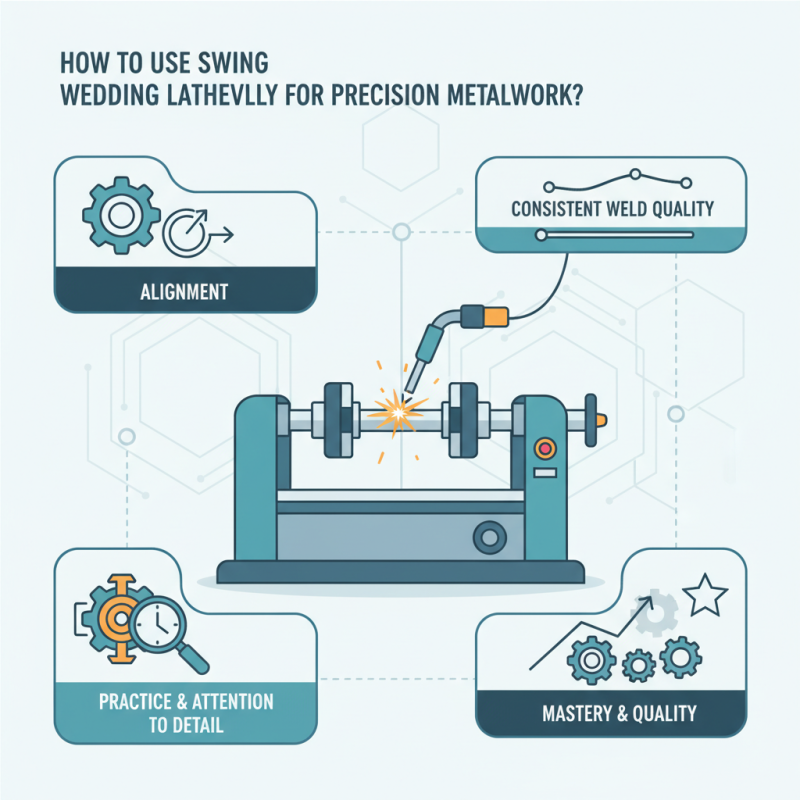

Many fabricators face challenges when utilizing this machinery. Common issues include alignment problems and inconsistent weld quality. These hurdles can diminish the craftsmanship often associated with skilled metalwork. However, with practice and attention to detail, using a Swing Welding Lathe can yield exceptional results.

Overcoming initial difficulties requires patience and persistence. Observing the intricacies of the lathe's movement is crucial. One can benefit from experimenting with different settings to understand its full potential. Although mastering the Swing Welding Lathe is a journey, the rewards for precision and quality are undeniable. Embracing this learning process is essential for any metalworker aiming for excellence in their craft.

Swing welding lathes are essential tools for precision metalwork. Their design allows for intricate shaping and welding processes. These lathes can accommodate large workpieces, typically up to 10 feet in diameter. However, achieving precision demands a careful understanding of their mechanics.

Proper setup is crucial. The lathe needs to be calibrated to avoid inaccuracies. Reports indicate that improper alignment can lead to tolerances exceeding 0.1 inches. When working with materials like steel or aluminum, a slight deviation can compromise the whole project. Regular maintenance of the machine is also necessary to ensure longevity and performance.

Operators often overlook the importance of feed rate. A slower speed may enhance precision but could also extend project timelines. Industry data reveals that nearly 30% of operators do not adequately adjust their feed rates for different materials. This oversight can result in subpar welds or increased wear on tools. Reflection on these aspects can lead to improved outcomes in metalworking.

Operating a swing welding lathe carries inherent risks. The American Welding Society reports that improper use contributes to nearly 20% of welding accidents. Proper safety measures are essential to mitigate these risks. Always wear appropriate personal protective equipment (PPE), including welding helmets, gloves, and protective clothing. This gear can reduce the risk of burns and eye injuries caused by sparks and intense light.

Ventilation is another crucial factor. Poor airflow can lead to the accumulation of harmful fumes. According to industry studies, about 60% of welders face respiratory issues due to insufficient ventilation. Implementing local exhaust systems can help remove harmful particles effectively. Regular checks on equipment can prevent malfunctions that may arise from neglect.

Training and awareness are vital. Many operators overlook the importance of understanding the machine’s specifics. A lack of knowledge can lead to significant mistakes. Familiarize yourself with the lathe’s operations, settings, and features before starting. Ignoring these elements can cost time and resources. Continuous learning and awareness of safety protocols should never be underestimated.

Setting up a swing welding lathe requires attention to detail. Begin by ensuring the lathe is positioned securely. It should be on a flat surface, away from any obstructions. Check the power source. A stable electric supply is crucial for consistent operation. Ensure safety measures are in place. Wear protective gear to avoid injuries.

Next, adjust the swing arm for the required material. This process can be tricky. If the arm isn’t aligned correctly, it may lead to uneven welding. Test the swing range with a suitable piece of scrap metal before starting on your project. Sometimes, calibration can feel tedious, but it’s important for precise results. Take note if adjustments are needed.

Once everything is set, focus on your welding technique. Start slow and steady. Watch for any flickering or instability in the arc. These can indicate a problem that needs addressing. It’s essential to find the right speed. Experimentation might be necessary to get comfortable. Remember, practice makes perfect, even if it takes time.

Swing welding lathes are invaluable for precision metalwork. Achieving high levels of accuracy requires a thoughtful approach. Start by ensuring proper setup. The workpiece must be securely fixed. This allows for smooth rotation, which significantly enhances the welding process. Use clamps or fixtures to stabilize the metal piece. An unsteady workpiece can lead to inconsistent welds.

Consider your welding technique carefully. Different materials behave differently under heat. Practice varying your speed and heat settings. This experimentation allows you to find the right balance for each project. Pay attention to the arc distance during welding. Too far or too close can affect the weld’s quality. It’s also helpful to regularly inspect your welds. Look for inconsistencies; they may reveal areas for improvement.

Lastly, keep your tools in top condition. Dull tools can compromise your precision. Regular maintenance is essential, even if it's sometimes overlooked. Each project is a learning experience. Reflect on what works and what doesn’t. This systematic evaluation can lead to better outcomes in future projects. Precision metalwork is an art and requires ongoing refinement.

| Technique | Description | Benefits |

|---|---|---|

| Proper Setup | Ensure the lathe is leveled and secured before starting any work. | Reduces vibrations and increases overall machining accuracy. |

| Tool Selection | Use the right tools for the material and type of work being performed. | Enhances precision and prolongs tool life, reducing costs. |

| Consistent Speed | Maintain a consistent speed throughout the operation. | Ensures uniform cuts and reduces the risk of overheating. |

| Regular Maintenance | Routine checks and lubrication of the lathe parts. | Increases longevity and performance of the lathe. |

| Cutting Depth Adjustment | Adjust the cutting depth according to the material being machined. | Prevents tool damage and enhances finish quality. |

To ensure long-lasting performance of swing welding lathes, routine maintenance is crucial. Neglecting this can lead to costly repairs. A study by the American Welding Society highlights that regular maintenance can extend machine life by up to 30%. Keeping equipment in top shape is not just about longevity; it's about precision, too.

Proper lubrication is essential. Check lubricants frequently. Dirty or low levels can cause friction and wear. Clean gears, bearings, and slides regularly. Dust can severely impact performance. A clean workspace helps maintain optimal conditions.

It’s important to inspect alignment regularly. Misalignment affects weld quality and efficiency. It can often go unnoticed until it’s too late. A simple check can prevent larger issues down the line. Also, keep an inventory of essential spare parts. This can save time and minimize downtime. Regularly review your maintenance routine for areas of improvement. Always be on the lookout for unusual noises or performance drops. Small details can indicate larger problems.