When embarking on a welding project, the choice of equipment can significantly impact the outcome. A Mini Welding Machine is a versatile tool that caters to both beginners and seasoned professionals, making it crucial to select the right one for your specific needs. According to welding expert John Smith, "Investing in the right mini welding machine not only enhances your craftsmanship but also saves time and effort in the long run." With a myriad of options available on the market, understanding the features that matter most can be overwhelming.

In this article, we provide ten essential tips to guide you in choosing the best Mini Welding Machine for your projects. From evaluating power requirements to understanding the types of welding processes, our comprehensive outline will equip you with the knowledge needed to make an informed decision. Whether you're working on small repairs, DIY projects, or intricate designs, the right mini welding machine can elevate your work quality and efficiency. Get ready to dive into the world of welding and discover the key factors that will help you select an ideal machine tailored to your creative aspirations.

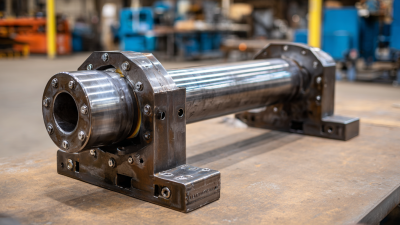

When selecting the right mini welding machine for your projects, it’s crucial to first assess your specific needs. Consider the materials you will be welding, as different machines excel in welding a variety of metals. For instance, if you'll mainly work with thin sheets, a MIG welder may be more suitable, while thicker materials may require a TIG welder. Ensure the machine you choose can handle the thickness and type of metals you plan to use.

Another key consideration is the machine's portability and weight. Mini welding machines are designed for ease of use, but if you plan to transport it frequently, opt for a lightweight option with a durable carrying case. Additionally, examine the available power sources—some machines operate on standard household outlets, while others may require 220V inputs.

Lastly, look into the features that enhance usability and safety. Machines with adjustable settings allow you to cater to different welding techniques, offering greater flexibility. Safety features such as thermal overload protection and automatic shut-off can provide peace of mind while working. By reflecting on these aspects, you can confidently choose a mini welding machine that meets your project demands.

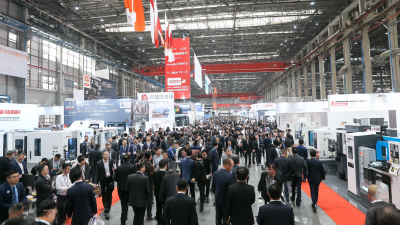

When selecting a mini welding machine, understanding the different types available is crucial for effective project execution. The market continues to expand, with a notable trends in equipment such as inverter welders, laser welders, and traditional MIG and TIG models. According to recent industry analysis, the welding equipment sector is projected to grow significantly, influenced by rising demand in manufacturing and repair sectors. In particular, laser welding machines are gaining traction for their speed and precision, particularly as businesses look to enhance productivity while minimizing costs.

Here are a few tips to keep in mind when choosing your mini welding machine: First, assess the material types you will be working with. Some machines are better suited to metals like aluminum versus stainless steel. Second, consider the power output of the welder; higher amperage provides more versatility. Lastly, don’t overlook simplicity and portability—ideal for small-scale projects or hobbyist work at home.

Additionally, the performance of small inverter welders can't be ignored, as they offer affordability without compromising efficiency. Many models are lightweight and user-friendly, catering especially to beginners entering the welding field. If you're leaning towards a plastic welding machine, options like airless models should not be discounted, given their consistent heat application and ease of handling.

When selecting a mini welding machine, understanding power requirements and performance features is crucial for ensuring optimal functionality for your specific projects. Start by assessing the type of materials you will be working with and the thickness of those materials. Different welding jobs, such as MIG, TIG, or stick welding, require varying levels of amperage. A machine with adjustable settings allows you to fine-tune the power output, catering to different welding tasks and enhancing overall performance.

In addition to power, consider the machine’s duty cycle, which indicates how long it can operate before needing a rest. A higher duty cycle is essential for extended projects, as it allows for more continuous work without overheating. Furthermore, explore features such as portability and ease of use, as these can significantly affect your welding experience. Look for machines with clear controls and lightweight designs if you plan to move the equipment frequently. By prioritizing these power requirements and performance features, you can select a mini welding machine that aligns with your project needs and improves your efficiency in achieving high-quality welds.

When selecting a mini welding machine, assessing portability and ease of use is crucial, especially for projects that require mobility. A lightweight design can significantly enhance the user experience, allowing you to move the machine between locations with minimal effort. Consider a model that features a compact build and a convenient carrying handle, making it easier to transport to job sites or workshops. Furthermore, battery-operated mini welding machines offer the ultimate in portability, enabling you to work in remote locations without the need for a power outlet.

Ease of use is another important factor to evaluate. Look for machines with intuitive controls and clear labeling, which can help novice welders quickly get started. Adjustable settings for voltage and amperage contribute to a more user-friendly experience, allowing for customization depending on the materials and thickness being welded. Additionally, models with built-in safety features, such as thermal overload protection, can provide peace of mind while you focus on your work. Ultimately, choosing a mini welding machine that excels in portability and usability will enhance your overall project efficiency and satisfaction.

When selecting a mini welding machine, safety features and certifications are paramount to ensure not only the quality of work but also the safety of the operator. Firstly, look for machines with built-in safety features such as overload protection, hot start, and anti-stick functions. These mechanisms can prevent overheating and accidental electrode sticking, which can pose risks during operation. Being aware of these features will lead you to a machine that minimizes the chances of accidents, making your welding experience more secure.

Additionally, check for relevant certifications that indicate compliance with safety standards. A good mini welder should meet safety regulations set by organizations such as the American National Standards Institute (ANSI) or Underwriters Laboratories (UL). These certifications assure you that the equipment has undergone rigorous testing for safety and reliability. Invest in equipment that is certified, as it reflects a commitment to maintaining safe operational protocols, which protects both the machine and the user during various welding projects.

| Feature | Description | Importance |

|---|---|---|

| Safety Certifications | Ensure the machine complies with local safety standards (e.g., CE, UL). | Critical for safe operation. |

| Overload Protection | Automatically shuts off to prevent overheating. | Essential for machine longevity. |

| Voltage Range | Check if it supports the power supply available. | Necessary for compatibility with your workspace. |

| Portability | Lightweight design for easy transportation. | Important for mobile projects. |

| Ease of Use | Intuitive controls and setup process. | Facilitates quicker project completion. |

| Duty Cycle | Length of time machine can operate continuously. | Critical for heavy workloads. |

| Welding Types | Capability to perform different types of welding (MIG, TIG, etc.). | Increases versatility for various projects. |

| User Reviews | Feedback from other users regarding performance and safety. | Provides real-world insight into functionality. |

| Warranty and Support | Length and terms of warranty, availability of support. | Important for long-term investment. |