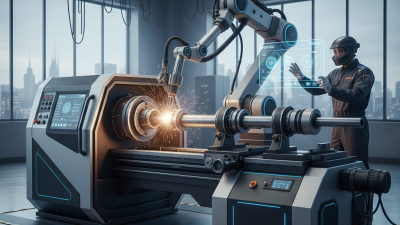

The Swing Welding Lathe is a powerful tool for welders, providing versatility and precision. Mastering its use can elevate your welding projects. Each angle and setting offers unique benefits, but they come with a learning curve.

Understanding the Swing Welding Lathe's components is crucial. The adjustments you make can affect the quality of your weld. Simple mistakes can lead to misalignments or weak joints. It's vital to practice regularly and reflect on each project for improvements.

Safety should always be a priority. While using the Swing Welding Lathe, keep protective gear on and ensure your workspace is clear. This tool can be intimidating at first, but with patience and practice, it becomes much easier to handle. You will find satisfaction in mastering its operations.

Swing welding lathes are vital tools in metalworking. Understanding their basics can significantly enhance your welding projects. These machines rotate workpieces, allowing for greater precision while welding. A study from the American Welding Society shows that nearly 60% of productivity in welding tasks can improve with proper tool use.

Tip 1: Always ensure your lathe is calibrated correctly before starting. Calibration affects accuracy and quality. A misaligned machine can lead to flawed welds, wasting materials and time.

Tip 2: Use the right type of tungsten electrode. The electrode choice can affect arc stability and weld quality. Inadequate selection can lead to inconsistent results.

Swing welding lathes also require regular maintenance. Ignoring routine checks can cause mechanical issues. Statistics show that regular maintenance can extend a machine’s lifespan by up to 30%. Keeping a clean workspace around the lathe is equally important. Clutter can lead to safety hazards. Keeping the area organized enhances focus and productivity during welding operations.

Choosing the right tools and equipment for your swing welding lathe is crucial for achieving optimal results. According to industry reports, over 70% of welding professionals agree that the quality of tools significantly impacts productivity. Selecting appropriate lathe accessories ensures smoother operation and better precision.

When equipping your lathe, consider essential tools like a high-quality chuck, proper tooling plates, and a reliable tailstock. These components can reduce setup times and improve accuracy. Many experts recommend investing in a versatile cutting tool set. This can be invaluable for varying project requirements. Skimping on tools might lead to frustrations. Subpar equipment often results in inconsistent welds and wasted material.

It is also vital to regularly assess your equipment. Routine maintenance can prevent unforeseen disruptions. A well-calibrated lathe operates more efficiently, according to data from manufacturing surveys. However, many professionals tend to overlook this aspect. Regular checks on alignment, tool sharpness, and lubrication can help maintain performance. Remember, even the best operators can struggle when using incorrect or inadequate tools. Prioritizing the right equipment leads to better quality and more efficient work.

Creating an optimized workspace for using a swing welding lathe can enhance productivity significantly. Start by selecting an appropriate location. Ensure the area is well-ventilated and has enough space to move around freely. A clutter-free environment can prevent accidents. Try to keep tools and materials in designated spots. This can ease the workflow.

Lighting is essential. Natural light is great, but if that's not possible, invest in good artificial lighting. Poor lighting can lead to mistakes and frustration. Regularly check that your lighting setup is functioning well. It’s easy to overlook but makes a big difference. Also, consider the layout. Keep frequently used tools within arm's reach. This prevents interruptions and breaks in focus.

Safety gear should always be within easy access. Sometimes, it can be tempting to skip using it for convenience. However, a moment of negligence can lead to serious issues. Reflect on your mistakes, and ensure safety is a priority. A comfortable chair and good posture can also enhance efficiency. Don’t underestimate these small adjustments; they add up. Finding the right balance in your workspace will make all activities smoother.

To maintain precision and accuracy while using a swing welding lathe, focus on the setup. The workpiece should be securely clamped. Any movement can lead to inaccuracies. Check the alignment of the lathe regularly. A slight deviation can result in poor weld quality. Ensure the tooling is clean and sharp. Dull tools can compromise your results, leaving rough edges and inconsistent welds.

During operation, monitor your feed rate closely. Too fast a feed can cause overheating. This may lead to distortion of the materials. Adjust your speed based on the material type. Remember, every material behaves differently under heat. Observe your welds as you progress. Look for signs of improper penetration or excessive spatter. Each weld is a learning opportunity. Analyzing mistakes helps refine your technique. Don’t hesitate to pause and make adjustments. Maintaining precision is an ongoing process that requires vigilance.

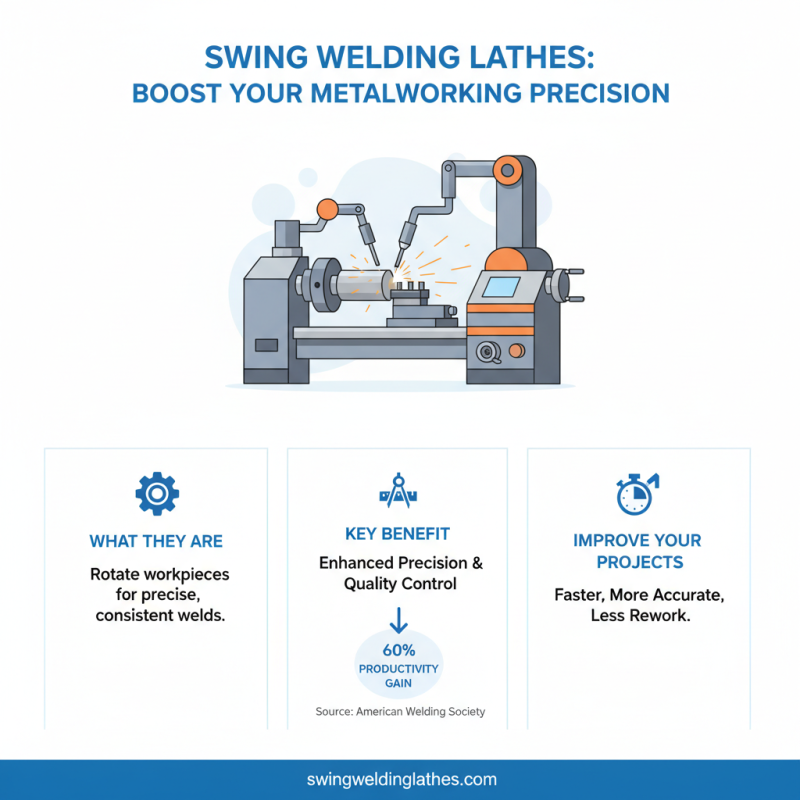

| Tip Number | Tip Description | Benefits | Effective Techniques |

|---|---|---|---|

| 1 | Regularly check and calibrate equipment. | Ensures accuracy and prolongs lathe life. | Use calibration tools and compare against standards. |

| 2 | Maintain clean working conditions. | Reduces contamination and enhances performance. | Use protective covers and regular cleaning schedules. |

| 3 | Use proper tooling and fixtures. | Enhances precision and efficiency. | Select high-quality tools specific to your job. |

| 4 | Perform routine maintenance and lubrication. | Keeps machine parts moving smoothly. | Create a maintenance log and follow service intervals. |

| 5 | Train and certify operators. | Ensures safe and effective operation. | Implement training programs and certification tests. |

| 6 | Optimize power settings for materials. | Improves cutting efficiency and quality. | Equip your lathe with power variables for adjustments. |

| 7 | Monitor tool wear regularly. | Maintains cutting quality and minimizes errors. | Set regular checks during operations. |

| 8 | Use coolant effectively. | Reduces heat and prolongs tool life. | Choose coolants suited for your materials. |

| 9 | Ensure proper workpiece setup. | Improves accuracy and reduces risks of accidents. | Check alignment and secure clamping. |

| 10 | Document operations and outcomes. | Enhances learning and continuous improvement. | Maintain logs for review and future references. |

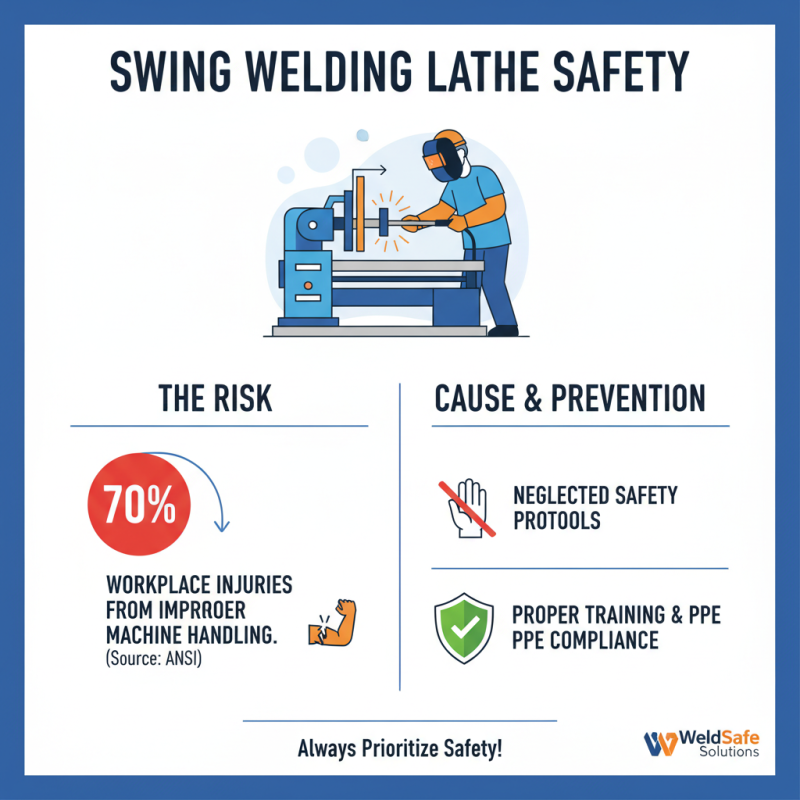

Using a swing welding lathe presents various safety challenges. According to the American National Standards Institute, 70% of workplace injuries stem from improper machine handling. Such incidents often involve operators neglecting safety protocols.

To ensure safety, operator training is crucial. Workers should use personal protective equipment, including helmets and gloves. It's surprising how many ignore these basics. Setting up the lathe properly is equally important. Ensuring all components are secure can prevent accidents. Many operators overlook routine maintenance checks, increasing risk.

Awareness of surroundings is vital. A crowded workspace can lead to disasters. Operators should also recognize the machine's limitations. Pushing the lathe beyond its capabilities can lead to equipment failure. Regularly reviewing safety protocols keeps workers alert and informed. Remember, safety protocols are in place to protect everyone involved.