The upcoming 138th Canton Fair in 2025 promises to be a pivotal event for the welding machine set industry, showcasing the latest innovations and trends that are shaping the future of this sector. According to a recent report by MarketsandMarkets, the global welding equipment market is projected to reach USD 23.64 billion by 2026, growing at a CAGR of 5.6% from 2021. This growth is largely driven by the increasing demand for automated welding processes and advancements in technologies such as robotics and AI integration.

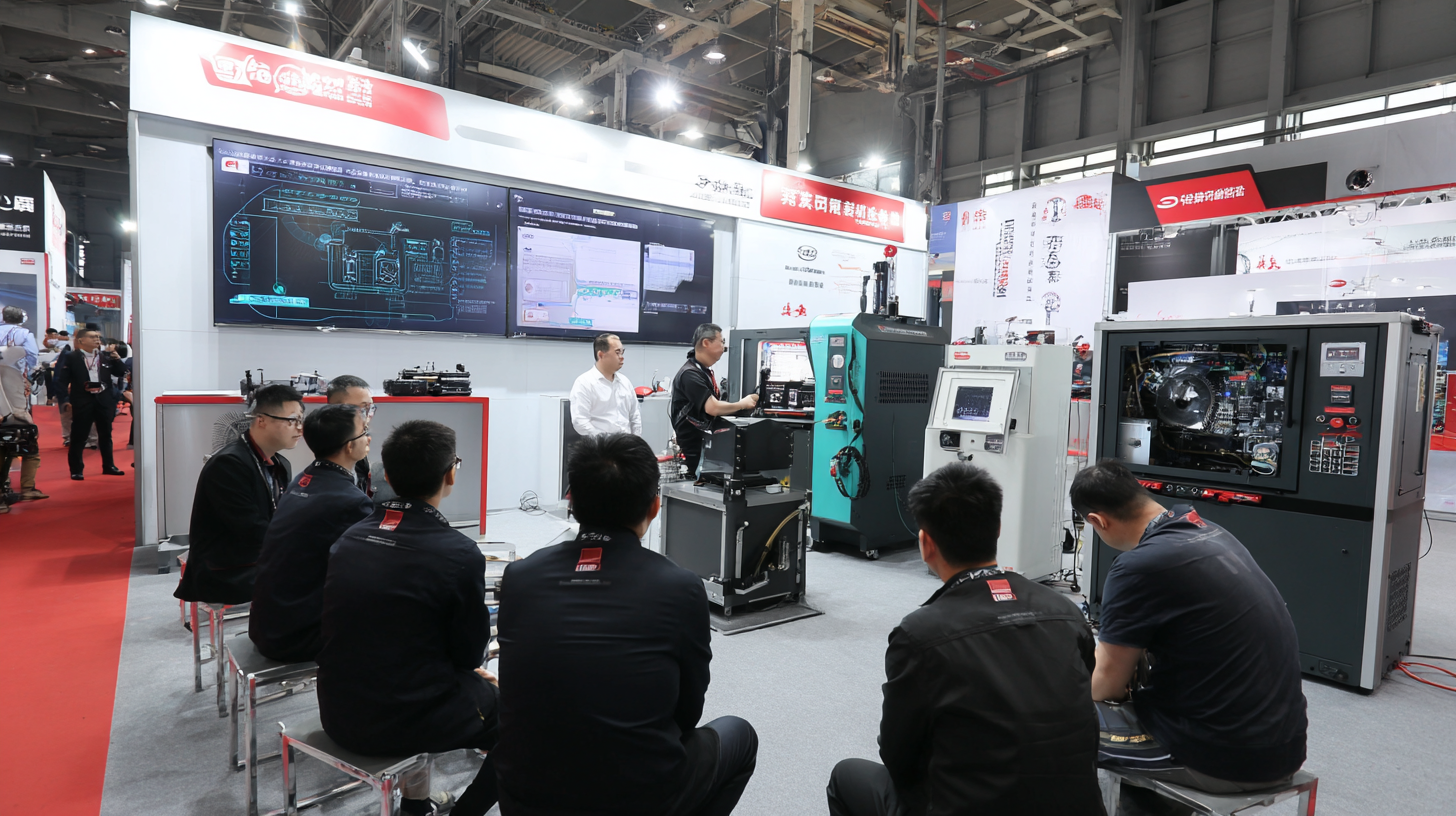

At the fair, industry leaders will present cutting-edge welding machine sets that incorporate smart features and enhanced sustainability measures, addressing the evolving needs of various manufacturing sectors. As manufacturers strive to improve efficiency and reduce costs while complying with stringent environmental regulations, the innovations displayed at the Canton Fair will be crucial for staying competitive in this rapidly evolving landscape.

The 138th Canton Fair is set to be a groundbreaking showcase for innovative welding technologies, presenting an opportunity for industry professionals to explore advancements that significantly enhance welding efficiency and quality. Reports indicate that the global welding equipment market is projected to reach $29.3 billion by 2026, growing at a compound annual growth rate (CAGR) of 4.1% from 2021 to 2026. This growth is largely driven by increasing automation and the demand for high-performance welding solutions across various sectors, including automotive, construction, and aerospace.

At the fair, attendees can expect to see cutting-edge technologies such as Laser Beam Welding (LBW) and Friction Stir Welding (FSW) which are gaining traction due to their ability to deliver superior results with minimal distortion. Industry analysts forecast that the adoption of these advanced techniques could boost productivity by up to 30%, addressing the growing need for precision in modern manufacturing. Furthermore, the emphasis on eco-friendly welding processes reflects the industry's ongoing commitment to sustainability, with reports suggesting that green welding technologies are set to capture a larger market share, reinforcing the trend towards environmentally responsible manufacturing practices.

The welding machine industry is poised for a transformative leap in 2025, driven by newly emerging trends in design and efficiency. As reported by the Allied Market Research, the global welding equipment market size is expected to reach $23.78 billion by 2025, with a projected compound annual growth rate (CAGR) of 5.6% from 2018. This growth is predominantly attributed to technological advancements and the increasing demand for high-quality welding in sectors such as construction, automotive, and manufacturing.

Innovations in welding machine design focus on integrating smart technologies, enhancing user-friendliness, and improving energy efficiency. The introduction of IoT-enabled welding machines allows for real-time monitoring of operations, which can significantly decrease downtime and increase productivity. Moreover, advancements in materials, such as lightweight and portable welding machines, are addressing the needs of modern industries seeking versatile solutions. The 138th Canton Fair 2025 will showcase these groundbreaking designs, emphasizing trends like automation and robotics that further push the boundaries of efficiency and quality in welding processes.

At the 138th Canton Fair 2025, the welding equipment sector is set to highlight the critical importance of sustainability and eco-friendly practices. As industries worldwide shift towards greener solutions, the welding machine sets are evolving to minimize environmental impact. Recent data from the Global Welding Equipment Market report indicates that the demand for eco-friendly welding machines is rising at a CAGR of 5.2%, as businesses prioritize compliance with stricter environmental regulations and aim to reduce their carbon footprint.

Innovations in welding technology are paving the way for more sustainable practices. For instance, manufacturers are increasingly adopting advanced power sources that increase efficiency while reducing energy consumption. The introduction of inverter technology and hybrid welding processes are notable advancements that allow for higher precision and reduced waste. According to a report by MarketsandMarkets, the global market for such advanced welding systems is expected to grow significantly, with eco-efficient machines projected to capture a substantial share by 2026. The continued focus on sustainability is not just a trend but a transformative approach that shapes the future of the welding industry.

The integration of smart technology into welding machinery is rapidly transforming the industry, particularly as showcased at the 138th Canton Fair in 2025. Innovations such as AI-driven robotic welding systems and advanced monitoring solutions are set to enhance precision and efficiency. These technologies are designed to provide real-time data analytics, enabling operators to mitigate risks, reduce downtime, and optimize workflows, which align with the growing emphasis on digital manufacturing.

In parallel, the laser welding machine market is projected to reach USD 4.7 billion by 2035, reflecting a robust CAGR of 5.2% between 2025 and 2035. This growth is propelled by an increasing demand for automation in sectors such as aerospace, automotive, and marine applications. Additionally, smart welding monitoring solutions are forecasted to gain traction, with expectations of reaching USD 2.3 billion by 2035. As industries continue to evolve, the fusion of smart technologies in welding machinery promises to redefine productivity benchmarks across various sectors, highlighting a significant trend towards innovative manufacturing practices.

| Feature | Description | Expected Impact | Potential Applications |

|---|---|---|---|

| Smart Sensors | Integration of IoT devices to monitor welding parameters in real-time. | Improved quality control and reduced defects. | Manufacturing, automotive, aerospace. |

| Automation | Use of robotic welding arms for precision and efficiency. | Increased production speed and reduced labor costs. | Heavy industries, construction, shipbuilding. |

| Data Analytics | Utilization of AI for analyzing welding data to optimize processes. | Enhanced decision-making and predictive maintenance. | Repair services, manufacturing optimization. |

| Wireless Control | Remote management of welding machines through mobile applications. | Increased flexibility and ease of use. | Utilities, construction sites. |

| Energy Efficiency | Development of machines that use less energy without compromising performance. | Cost savings and reduced environmental impact. | Sustainable manufacturing practices. |

| Augmented Reality (AR) | Use of AR for training and visualizing welding processes. | Improved training outcomes and reduced errors. | Education, industrial training. |

The global market for welding machines is poised for remarkable growth, projected to rise from $64.64 billion in 2025 to $82.78 billion by 2032, reflecting a compound annual growth rate (CAGR) of 3.6%. This positive outlook indicates not only increasing demand but also the emergence of new opportunities in the industry. As advancements in technology continue to shape the welding landscape, manufacturers are focusing on innovations that enhance productivity and efficiency, catering to diverse applications.

Industrial welding robots are a significant driving force behind this growth. Segmented by function, the market includes spot welding, arc welding, and laser welding robots, each serving specific needs across various sectors such as automotive, electronics, aerospace, and defense. The integration of intelligent automation and robotics in welding processes is expected to redefine operational standards, making it imperative for manufacturers to stay ahead of emerging trends and consumer expectations.

With the 138th Canton Fair in 2025 showcasing these innovations, stakeholders are encouraged to explore the vast potential within the welding machine market.