In today's highly competitive manufacturing landscape, optimizing the use of a Fiber Welder Machine is more crucial than ever. According to a report by MarketsandMarkets, the global market for fiber welding technology is projected to reach $5.2 billion by 2026, driven by the increasing demand for high-efficiency and precision welding processes across various industries. With advancements in laser technology and automation, manufacturers can achieve unparalleled levels of productivity and cost savings. However, many operators still overlook essential practices that can significantly enhance the performance of their fiber welding systems. By adopting industry best practices and understanding the intricate functionalities of a Fiber Welder Machine, users can not only improve their operational efficiency but also extend the lifespan of their equipment. This guide will outline effective strategies to maximize efficiency with your Fiber Welder Machine, ensuring that you stay ahead in an ever-evolving market.

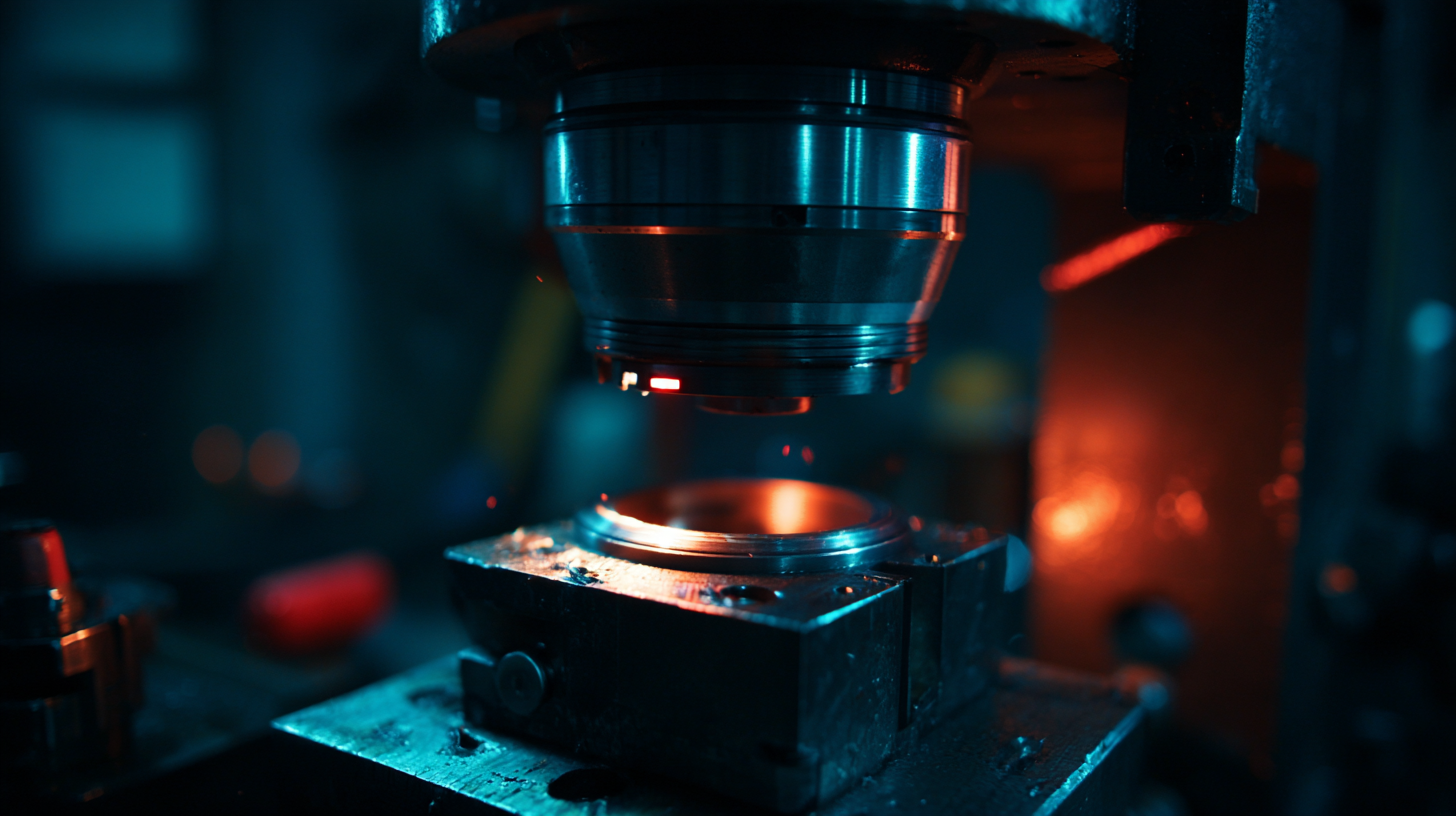

Understanding the basics of fiber welder machines is crucial for achieving optimal performance. A fiber welder operates using a high-powered laser that melts the base materials together, forming strong and durable joints. To maximize efficiency, it’s essential to familiarize yourself with the machine's key components, such as the laser source, focusing lens, and cooling system. Each element plays a vital role in the welding process, influencing both the quality of the weld and the speed of production.

Furthermore, proper settings and adjustments significantly impact the performance of fiber welder machines. Operators should understand how factors like laser power, welding speed, and travel angles can be optimized for different materials and thicknesses. Regular maintenance and calibration are also necessary to ensure the machine operates at peak efficiency. By mastering these fundamentals, users can not only increase productivity but also enhance the reliability of their welds, leading to improved overall outcomes in fabrication tasks.

To keep your fiber welder running smoothly, regular maintenance is crucial. One effective tip is to routinely clean the optics. Dust and debris can accumulate on the lenses, impairing the machine’s performance. Use a soft, lint-free cloth and proper cleaning solutions specifically designed for optical components. This simple step can significantly enhance the quality of your welds and extend the life of your machine.

Another vital maintenance tip is to check the cooling system. The fiber welder generates a substantial amount of heat during operation, so ensuring the cooling system is functioning optimally is essential. Regularly inspect the coolant levels and the condition of the cooling pump. Monitor the temperature readings during operations; if they exceed recommended levels, it might indicate a problem that needs addressing before it leads to more significant issues.

Additionally, keep an eye on the alignment of your fiber welder. Misalignment can cause inconsistent welds and premature wear on components. Regularly calibrate the machine according to the manufacturer’s guidelines, and adjust as needed to ensure precision in your work. With these maintenance practices, you can maximize the efficiency of your fiber welder machine and maintain its longevity.

This bar chart illustrates the efficiency percentage of fiber welder machines over a six-week maintenance period. Regular maintenance tends to improve overall performance, as indicated by the increase in efficiency from weeks 2 to 4, followed by a decrease due to potential wear and tear before maintenance in week 5.

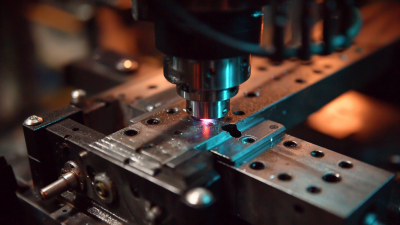

Maximizing efficiency with fiber welder machines involves implementing specific techniques that significantly enhance both welding speed and precision. According to a report by the American Welding Society, fiber laser welding can provide up to a 50% increase in welding speed compared to traditional methods. This is largely due to the faster laser pulse rates and the ability to focus beams more precisely, allowing for deeper penetration and minimal heat-affected zones. Incorporating advanced optics can further optimize the beam profile, ensuring consistent energy delivery throughout the welding process.

Moreover, precision can be enhanced through the use of adaptive control systems. A study published by the International Journal of Advanced Manufacturing Technology revealed that integrating real-time feedback loops in fiber welding machines can improve dimensional accuracy by up to 30%. These systems continuously monitor the welding process, adjusting parameters such as laser power and travel speed on-the-fly to adapt to varying material conditions. Implementing these strategies not only increases productivity but also enhances the quality of welds, reducing the need for post-weld processing and ensuring higher structural integrity in the final products.

| Technique | Expected Speed (m/min) | Precision (% Accuracy) | Ease of Implementation (1-5 Scale) |

|---|---|---|---|

| Optimal Focus Control | 15 | 98 | 4 |

| Material Pre-heating | 12 | 95 | 3 |

| Regular Calibration | 10 | 97 | 5 |

| Using Quality Lens | 14 | 99 | 4 |

| Optimized Parameter Settings | 13 | 96 | 4 |

When operating a fiber welder machine, selecting the right settings for different materials and applications is crucial for maximizing efficiency and achieving optimal results. According to a report from the Laser Institute of America, improper settings can lead to a decrease in weld quality by up to 30%, highlighting the importance of understanding material properties and their interaction with laser technology. For metals such as stainless steel, it is recommended to use a laser power between 1000 to 2000 watts, with a feed rate tailored to the thickness of the material to ensure deep penetration and minimize distortion.

In contrast, when working with plastics, the settings differ significantly. Research published in the Journal of Materials Processing Technology shows that using lower power levels (around 500 to 800 watts) with a faster feed rate can prevent thermal damage and warping. Additionally, adjusting the pulse duration and frequency for different plastic types can enhance the weld strength and appearance. By carefully selecting and fine-tuning these parameters based on the specific materials and their applications, operators can achieve better weld integrity and efficiency, ultimately leading to significant time and cost savings in production.

When operating a fiber welder machine, ensuring safety and efficiency is paramount. According to recent industry insights, integrating advanced sensor technologies significantly enhances the operational precision of welding processes. For instance, the use of sensors can improve welding accuracy by up to 30%, reducing the frequency of defects and rework, which directly contributes to increased efficiency and reduced operational costs. This aspect aligns with the best practices necessary for maximizing performance while maintaining safety standards.

Additionally, adhering to established safety guidelines is crucial, as highlighted by numerous studies regarding hazards in welding operations. It is essential for operators to receive comprehensive training on safe bending and welding techniques. Regular safety audits and the adoption of newer welding methods, such as hand-held laser welding, can mitigate risks. Notably, transitioning to these advanced techniques can increase welding speeds significantly—reports suggest rates up to four times faster than traditional methods, enabling more productive workflows while safeguarding the well-being of personnel. By fostering an environment that prioritizes safety alongside innovative practices, operators can maximize the efficiency of fiber welding operations.