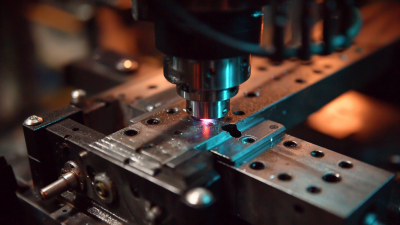

In the realm of heavy industries, efficiency and precision are paramount, particularly in the welding processes that form the backbone of structural integrity and durability. The Weld Roller Carriage has emerged as an essential tool, streamlining operations by providing seamless movement and support for welded materials.

This ultimate guide aims to delve into the various types of weld roller carriage solutions available, illustrating how they can be tailored to meet the specific demands of diverse industrial applications.

By maximizing the efficacy of these systems, businesses can significantly enhance productivity, reduce downtime, and ensure the highest quality standards in their welding projects.

Whether you're a seasoned professional looking to upgrade your machinery or a newcomer eager to understand the options available, this guide will serve as a comprehensive resource for selecting the ideal weld roller carriage solution to elevate your operational capabilities.

Weld roller carriages are essential components in heavy industries, designed to enhance the efficiency and accuracy of welding operations. These carriages support the movement of welding equipment along a predetermined path, ensuring seamless and consistent motion during the welding process. Understanding their fundamentals involves recognizing their design features, such as load capacity, materials used, and the various adjustments available for different welding applications. These considerations are critical, as they directly impact the productivity and effectiveness of welding tasks.

In addition to their structural aspects, the functionality of weld roller carriages is heavily influenced by the type of welding being performed. For instance, in heavy-duty applications like shipbuilding or manufacturing of large structures, the roller carriages must accommodate significant weight and provide stability under dynamic conditions. The mechanism’s operation, which can range from manual to automated systems, further adds to the versatility of these tools. A thorough grasp of these fundamentals enables industries to optimize their welding processes, reduce downtime, and ultimately maximize output while maintaining high-quality standards.

The design of weld roller carriages plays a vital role in maximizing efficiency in heavy industries. Key factors influencing their design include stability, load capacity, and adaptability to various welding techniques and materials. For instance, heavy-duty carriage systems can support significant welding tasks, allowing for the processing of materials up to 1/2 inch thick in a single pass. This not only streamlines operations but also reduces the total welding time, thereby enhancing productivity.

Moreover, the integration of advanced robotics in welding operations is gaining traction. A report by the International Federation of Robotics indicates that the implementation of robotic welding solutions can increase production efficiency by up to 30%. Consequently, the incorporation of intelligent systems in weld roller carriage designs can further optimize workflow and ensure precision, contributing to overall operational success. As industries seek to bolster their productivity, understanding these key design factors becomes essential for achieving superior outcomes in welding operations.

In the heavy industries sector, the performance of weld roller carriages is significantly influenced by the selection of materials. According to a report from the American Welding Society (AWS), improper material choice can lead to a decrease in efficiency and increased maintenance costs, often rising by up to 20% annually. High-strength steel and aluminum alloys are commonly recommended for their excellent durability and weight-to-strength ratio, which plays a crucial role in enhancing the operational lifespan of weld roller carriages.

Tip: Always evaluate the environmental conditions, such as humidity and temperature, as these can affect material performance. For instance, stainless steel is suitable in corrosive environments, ensuring that weld roller carriages remain functional with minimal risk of wear.

Moreover, incorporating advanced coatings such as thermoplastic or powder coatings can significantly extend the life of these carriages. A study published in the Journal of Material Science indicates that coated surfaces can improve abrasion resistance by nearly 30%. This not only reduces downtime but also enhances productivity in heavy-duty operations.

Tip: Regularly assess and replace worn-out components before significant issues arise to maintain optimal performance. Periodic inspections can save costs and ensure uninterrupted workflow.

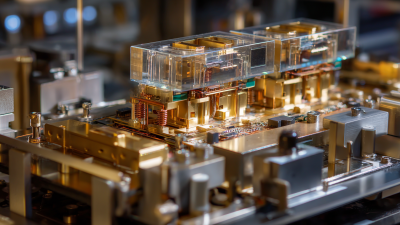

In today’s heavy industries, the integration of automation technologies into weld roller carriage operations is proving essential for maximizing efficiency and achieving higher levels of productivity. Automated systems not only streamline the welding process but also enhance precision and reduce human error. By deploying technology such as programmable logic controllers (PLCs) and real-time monitoring systems, companies can optimize workflow and ensure consistent quality in their welding projects.

Tips: When selecting automation components for weld roller carriages, prioritize systems that offer seamless integration with existing equipment. This can minimize downtime during deployment and ensure that technology updates do not disrupt ongoing projects. Regular training sessions for staff on the new automated systems further enhance efficiency—which is vital in keeping the workforce adept and responsive to technology changes.

Moreover, leveraging data analytics allows organizations to track performance metrics and identify areas for improvement within their welding processes. By analyzing trends and patterns in the operational data, organizations can make informed decisions that lead to better resource management and reduced operational costs. Transitioning to automated weld roller carriage solutions can thus pave the way for transformational changes in heavy industry operations.

In heavy industries, the implementation of weld roller carriage solutions has demonstrated significant efficiency gains across various applications. For instance, according to a recent report by Allied Market Research, the global market for welding automation is projected to reach $21.6 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.8%. This growth is largely driven by the adoption of sophisticated welding technologies, including weld roller carriages, which streamline the production process and enhance accuracy in large-scale fabrications.

Case studies from the automotive and aerospace sectors illustrate the tangible benefits of these systems. A leading automotive manufacturer reported a 30% reduction in weld cycle times after integrating a state-of-the-art weld roller carriage system into their production line. Similarly, an aerospace component supplier noted a substantial improvement in weld quality and consistency, resulting in a 25% decrease in rework costs. These examples underscore how weld roller carriage solutions not only optimize workflow but also significantly impact the bottom line in heavy industries.

| Industry | Weld Roller Carriage Type | Implementation Challenges | Key Benefits | Efficiency Improvement (%) |

|---|---|---|---|---|

| Automotive | Heavy-Duty Roller Carriage | Space Constraints | Increased Precision in Welding | 30% |

| Shipbuilding | Customizable Carriage Systems | Heavy Loads | Improved Load Distribution | 25% |

| Construction | Portable Roller Systems | Mobility Issues | Enhanced Flexibility on Site | 20% |

| Aerospace | Precision Alignment Carriages | High Tolerance Requirements | Increased Accuracy | 35% |

| Energy | Heavy-Duty Track Systems | Environmental Factors | Enhanced Durability in Harsh Conditions | 15% |