The advancement of technology in the realm of manufacturing has catalyzed a significant transformation in various industries, particularly in the field of jewelry and precious metals. Among these innovations, the Gold Cutting Machine stands out as a pivotal tool that enhances precision and efficiency in gold processing. According to a recent market analysis report by Research and Markets, the global gold cutting machine market is projected to grow substantially, with a compound annual growth rate (CAGR) of over 5% from 2023 to 2030. This staggering growth can be attributed to the increasing demand for intricate designs and high-quality finishes in jewelry manufacturing. As traditional methods give way to automated and computer-controlled solutions, businesses are increasingly adopting advanced gold cutting technologies to improve yield and reduce waste. The future of gold cutting machines promises not only to optimize production but also to revolutionize the artistry of gold craftsmanship, setting new standards in the industry.

The evolution of gold cutting technologies has dramatically transformed the landscape of gold mining, shifting from manual techniques to sophisticated machinery. In historical contexts, gold mining relied heavily on rudimentary tools and labor-intensive methods, leading to inefficiencies and limited extraction capacities. However, advancements in technology herald a new era where precision and automation reign supreme. Modern equipment, projected to evolve significantly by 2025, will enhance extraction rates by up to 30%, showcasing how technological innovation is reshaping the industry.

As we look toward the future, continuous mining systems and advanced cutting machinery are set to revolutionize operations. These machines not only improve extraction efficiency but also enhance safety standards and environmental sustainability. According to recent reports, implementing modern gold cutting technologies will allow for greater precision, reducing waste and increasing the overall yield of mined gold.

Tips: When considering upgrading to new gold cutting technologies, evaluate the potential return on investment by comparing the efficiency of current methods versus modern options. Additionally, stay informed on the latest trends in equipment maintenance to ensure longevity and reliability in your mining operations. Investing in training for your team on new technologies can also significantly impact productivity and safety in the field.

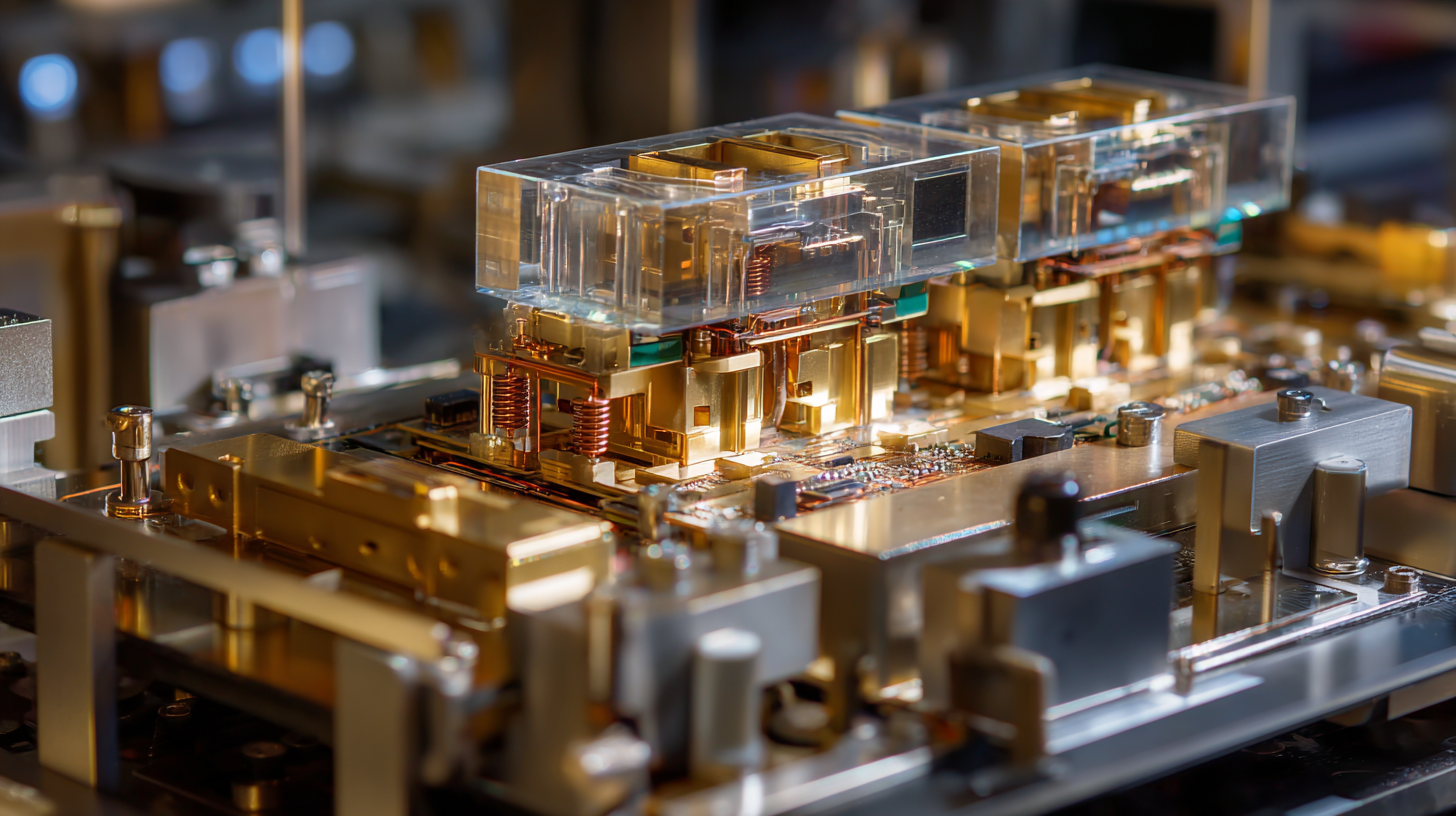

Next-generation gold cutting machines are set to transform the precision manufacturing sector with advanced features that significantly enhance efficiency and accuracy. These machines are being designed with smart technologies, including automated systems that allow for real-time adjustments and monitoring, reducing the need for extensive manual intervention. The integration of AI and machine learning facilitates predictive maintenance, ensuring that operations remain uninterrupted while minimizing downtime. According to industry reports, these advancements could improve operational efficiency by as much as 30% over traditional models.

One key feature of next-generation gold cutting machines is their ability to utilize ergonomic design principles, making them user-friendly even for operators with limited experience. As the industry faces a shortage of skilled operators, these intuitive controls are critical for simplifying complex processes, enabling faster learning curves, and boosting productivity. Utilizing versatility, these machines can accommodate various gold grades and cutting specifications, broadening their applicability across different sectors.

Tips: When investing in gold cutting technology, consider the machine’s ability to adapt to future technological advancements. Also, look for models that incorporate sustainability features, as they can lead to long-term savings and environmental benefits. Lastly, prioritize ease of use, which can significantly decrease training time and increase return on investment.

Precision cutting in gold jewelry production allows artisans to achieve intricate designs that were once labor-intensive and time-consuming.

With the advent of advanced gold cutting machines, manufacturers can now create elaborate patterns and details with unparalleled accuracy.

This not only enhances the aesthetic appeal of the jewelry but also increases production efficiency, allowing businesses to meet the rising demands of consumers looking for unique, high-quality pieces.

Moreover, precision cutting minimizes material waste, which is crucial in an industry where raw materials can be costly. By utilizing optimized cutting techniques, manufacturers maximize the yield from every piece of gold, leading to more sustainable practices.

This innovation not only benefits producers economically but also aligns with the growing consumer preference for ethically produced jewelry.

As precision cutting technology continues to evolve, it promises to further revolutionize the gold jewelry market, offering exciting possibilities for both craftsmen and consumers alike.

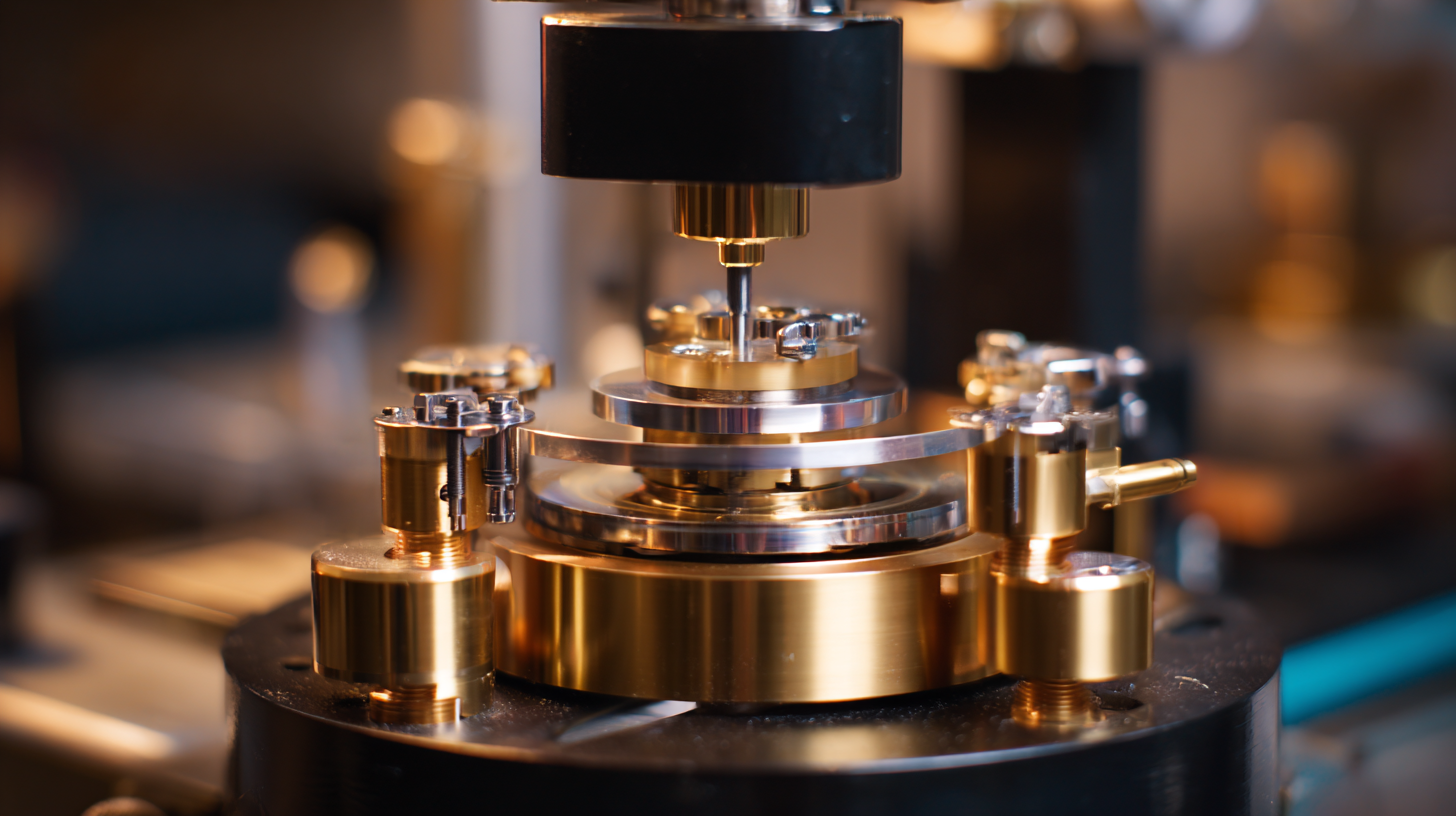

When selecting a gold cutting machine for your business, several critical factors should be considered to ensure optimal performance and reliability. First and foremost, assess the machine's precision capabilities. A machine that boasts high precision will reduce material wastage and improve overall efficiency. Look for models that offer advanced cutting technologies, such as laser or waterjet cutting, which can provide clean edges and intricate designs that are essential in gold crafting.

Another important aspect to consider is the machine's compatibility with your production volume and workflow. Ensure that the chosen equipment can handle your specific workload without compromising quality. It's beneficial to evaluate the machine's software for ease of use, as user-friendly interfaces can significantly enhance productivity. Additionally, consider the availability of support and servicing from the manufacturer, as ongoing maintenance is vital for the longevity of the cutting machine. By carefully weighing these factors, you can make an informed decision that aligns with both your operational needs and budget.

The landscape of gold cutting machinery is undergoing a significant transformation thanks to advancements in technology and engineering. As industries demand higher precision and efficiency, innovations are emerging that redefine the capabilities of gold cutting techniques. One notable trend is the adoption of laser cutting technology, which offers unparalleled accuracy and minimizes material waste. This method enables jewelers and manufacturers to create intricate designs with less manual intervention, thus enhancing productivity and reducing production times.

Another significant advancement is the integration of smart technology into gold cutting machines. Equipped with sensors and AI algorithms, these machines can now monitor cutting conditions in real-time, adjusting parameters automatically to optimize performance. This capability not only increases the lifespan of the machinery but also ensures that each piece of gold is cut with consistent quality. With these innovations, the future of gold cutting promises to be not only more efficient but also more sustainable, aligning with the broader trend of eco-friendly practices in manufacturing.

| Technology | Cutting Method | Precision Level | Applications | Future Trends |

|---|---|---|---|---|

| Laser Cutting | Thermal | High Precision | Jewelry Making, Electronics | Increased Automation |

| Water Jet Cutting | Mechanical | Moderate Precision | Artistic Designs, Industrial Parts | Eco-friendly Practices |

| Diamond Cutting | Mechanical | Ultra Precision | Luxury Goods, Custom Jewelry | Innovative Materials |

| EDM (Electrical Discharge Machining) | Electrical | High Precision | Molds, Complex Shapes | Integration with AI |

| CNC Milling | Mechanical | High Precision | Engineering, Prototyping | Smart Manufacturing |