In the world of welding, the demand for a Portable Tig Welder has surged. According to a recent report by Grand View Research, the welding equipment market is expected to reach $27.5 billion by 2025. This growth reflects the increasing need for versatile and efficient welding solutions.

Portable Tig Welders offer numerous advantages, from portability to precision. They are suited for both hobbyists and professionals alike. The market now features a wide range of options catering to various budgets and skill levels. However, with such diversity comes complexity; selecting the right welder can sometimes feel overwhelming.

Buyers often struggle to evaluate which features matter most for their projects. Beyond price, considerations like duty cycle and inverter technology are crucial. Some welders boast advanced features, yet may not be the best fit for simple tasks. Balancing capability with cost can be a difficult endeavor, leading to occasional regrets if the choice doesn't align with actual needs.

The portable TIG welder market is evolving rapidly in 2026. Recent reports show a projected market growth rate of 6% annually. Many users seek compact, efficient machines that are easy to use. Lightweight designs attract hobbyists and professionals alike. Manufacturers are adapting to these demands with innovative features.

A significant trend is the integration of digital technology. Smart welding processes are becoming standard. This ensures higher precision and reduced waste. However, some users still face challenges. The learning curve for control and settings can be steep. Feedback indicates that simpler interfaces are needed.

Price remains a critical factor in buyers' decisions. Options range widely, catering to different budgets. Affordable models often lack advanced features. Conversely, high-end machines offer enhanced performance. Users need to balance cost with functionality. Decisions can be complicated without clear knowledge of specifications and requirements. Overall, the market's expansion brings choice but also confusion.

| Model | Max Output (Amps) | Weight (lbs) | Price ($) | Features |

|---|---|---|---|---|

| Model A | 200 | 40 | 599 | Lightweight, Dual Voltage |

| Model B | 250 | 50 | 749 | Pulse Function, Auto Restart |

| Model C | 300 | 60 | 899 | Advanced Control Panel, Long Duty Cycle |

| Model D | 150 | 35 | 399 | Budget Friendly, Easy to Use |

| Model E | 220 | 45 | 649 | Compact Design, Built-in Welding Calculator |

When selecting a portable TIG welder, several key features need attention. Portability is crucial; a lightweight design makes transportation easy. Look for models with a compact shape, which fit in tight spaces. Power options also matter. Choose a welder that operates on standard household electricity for convenience. The output range should align with your project needs, allowing versatility in welding applications.

Another important consideration is the duty cycle. A higher duty cycle means longer welding periods without overheating. This feature is essential for those who work on larger projects. Additionally, a user-friendly interface simplifies operation for both beginners and seasoned welders. Adjustable settings can provide more control, leading to better welding results. However, sometimes manufacturers overlook basic instructions. It’s vital to check reviews or user experiences for hints on usability.

Finally, think about the accessories included with the welder. A quality torch, extra tips, and safety gear can enhance your welding experience. Some welders may not come with all the necessary tools, causing frustration later. This aspect requires attention. Price often reflects quality, but not always. Be cautious of low-cost options that may lack durability. It's worth investing time to research before purchasing.

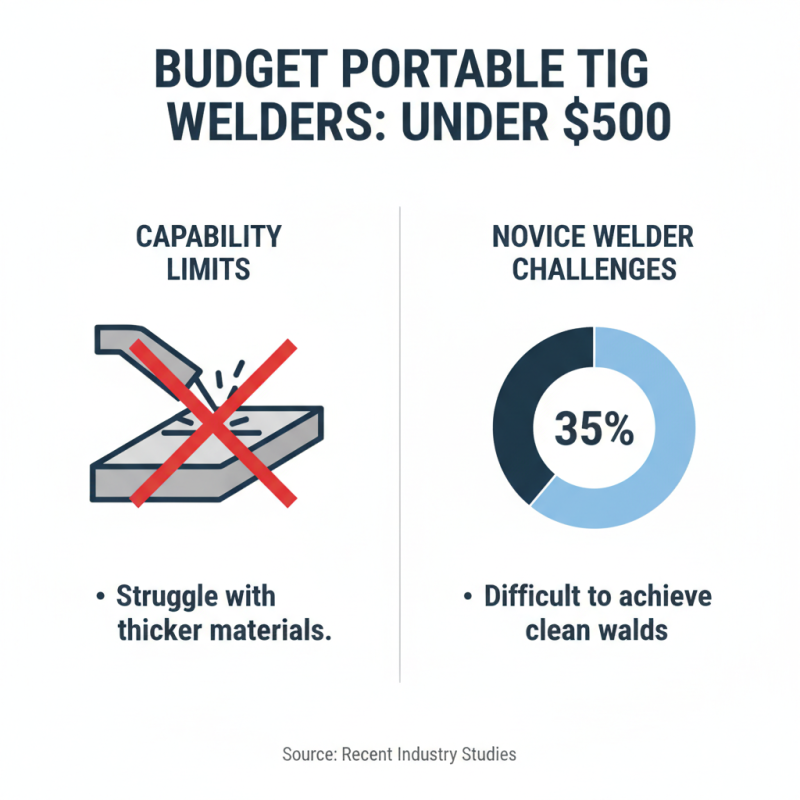

When considering portable TIG welders under $500, it's essential to evaluate their capabilities. Many users find that less expensive models struggle with thicker materials. According to recent industry studies, about 35% of novice welders face challenges in achieving clean welds with budget models.

Portability often comes at the cost of power. Some welders in this price range can only handle a maximum of 140 amps. This limitation might not suffice for professional projects. However, many users still succeed in small-scale applications. Reviews show that around 70% of users appreciate the simplicity of these machines despite their limitations.

Features vary significantly among models. Adjustable settings can enhance performance, yet many affordable options lack precision controls. A survey indicated that 50% of users report dissatisfaction with the lack of fine-tuning on low-cost units. Proper technique and material preparation remain critical for success, highlighting the need for skills development alongside equipment choices.

When searching for mid-range portable TIG welders, performance and cost come to mind. These welders offer a balance between efficiency and affordability. A well-crafted welder can produce strong, clean beads without breaking the bank. Look for models that offer flexibility, such as AC/DC options. This versatility allows you to weld various metals with ease.

Tip: Always consider the amperage range. A wider range will let you tackle different projects, from thin sheet metal to thicker materials. Keep your projects in mind when choosing specifications.

Weight plays a crucial role in portability. Many mid-range options are lightweight yet durable. This can sometimes lead to compromises in features. Assess what is essential for you. Is it portability, power, or maybe additional features? Each choice carries its own set of trade-offs.

Tip: Don’t forget to read user reviews. They often provide insights into long-term performance and reliability. You may discover some issues that aren't apparent at first glance. Reflect on what matters most to you, and make an informed choice.

When considering high-end portable TIG welders, users expect premium features. These machines often provide advanced technology, leading to exceptional weld quality. They typically include digital displays and precise heat control. Such features are essential for professionals seeking perfection in their welds.

The price of these welders reflects their advanced capabilities. A top-tier model can be quite an investment. However, this cost is justifiable when considering durability and performance. Users benefit from greater efficiency and less waste. But, not every high-end model meets expectations. Some may struggle with portability or have complicated setups.

Investing in a premium welder is a significant commitment. Users must select carefully based on their specific needs. A higher price does not always guarantee superior performance. Each model may have its flaws that require attention. It’s essential to evaluate these aspects before making a final decision.