In the manufacturing sector, the application of Track Welding Lathes is crucial for efficient production. According to a recent market report by Global Industry Analysts, the demand for welding lathe equipment is projected to grow by 5% annually. This emphasizes the necessity of understanding their diverse applications.

Industry expert Dr. Henry Hargrove states, "Track Welding Lathes are transformative tools that enhance precision in metal fabrication." His insights highlight the importance of these machines. They are not just tools; they represent an evolution in engineering processes.

While the benefits are significant, challenges exist. Many companies still struggle with the integration of advanced lathes into existing workflows. A lack of skilled operators can hinder progress. Awareness of these issues is vital as we explore the top applications of Track Welding Lathes.

Track welding lathe technology plays a crucial role in various industrial applications. It combines precision welding with lathe operations, enhancing efficiency in processes. This technology allows for seamless joining of materials while achieving high accuracy.

One significant advantage is its versatility. Track welding lathes can be used for manufacturing components in automotive, aerospace, and construction industries. However, imperfections can occur, leading to misalignments in welded parts. This might result in additional rework, which consumes valuable time and resources.

Understanding the operational aspects of track welding lathes is essential. Operators must be trained thoroughly. Familiarity with the equipment can minimize mistakes. Additionally, regular maintenance of the lathes prevents breakdowns. Ignoring this can lead to costly delays in production. By recognizing these factors, businesses can optimize their use of track welding lathe technology.

Track welding lathes play a vital role in modern manufacturing. Their precision and efficiency optimize welding processes across various industries. These machines are designed to handle large components, allowing manufacturers to weld pipes, frames, and other structures with superior accuracy. According to industry data, using track welding lathes can improve productivity by up to 30%, enabling faster project completion times.

One key feature of track welding lathes is their adjustable speed settings. This flexibility allows operators to adjust the welding process based on material type and thickness. Additionally, many lathes include automated systems that enhance repeatability in production. Such automation decreases the likelihood of human error, which can lead to defects and rework.

Tips: Always calibrate your track welding lathe before use. Regular maintenance extends the machine's lifespan. Training operators to handle these machines is also crucial, as improper use can result in errors and costly downtime. Being aware of these factors is essential for maintaining efficient operations in manufacturing.

Track welding lathes play a crucial role in various industries. They are often used in manufacturing processes that require precision and efficiency. Industries such as automotive, aerospace, and heavy machinery rely heavily on these machines. According to industry reports, the global market for welding lathes is expected to grow by over 5% annually through the next five years. This highlights their importance in modern manufacturing.

The automotive industry utilizes track welding lathes for components like frames and structural parts. These lathes ensure strong, reliable joins essential for vehicle safety. Aerospace manufacturers also benefit from the precision offered by track welding lathes. Here, the tolerances are tight, and the materials often require specialized welding techniques.

Tip: Regular maintenance can extend the life of your track welding lathe. This can lead to improved efficiency and a reduction in costly repairs. Another consideration is the need for operator training. Skilled operators can make significant differences in product quality and production speeds.

However, it is worth reflecting on the learning curve involved in using these machines. Some operators may struggle to master them initially, leading to potential delays in production. Each industry faces different challenges, and addressing these requires ongoing education and adaptation.

Track welding lathes play a crucial role in several industries. In the construction sector, they are often used to weld large steel structures. This application requires precision and stability, allowing for strong and durable joints. In shipbuilding, these lathes can efficiently weld hull components. The ability to reposition the lathe on a track makes it ideal for large-scale projects.

Manufacturing is another sector benefiting from track welding lathes. Here, they are used for creating machinery parts. The versatility of these lathes helps in achieving consistency and quality. However, some users face challenges with alignment and calibration. Fine adjustments are necessary, and not everyone gets it right.

In the railways, track welding lathes are essential for joining rails together. This process ensures safety and reliability. Nevertheless, the learning curve can be steep for new operators. Mistakes in welding can lead to serious issues. Each application has its unique demands, making it essential for users to remain vigilant and continually learn.

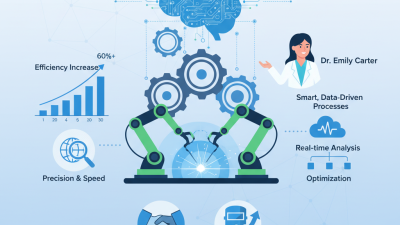

Track welding lathes continue to evolve, driven by technological advancements and industry demands. According to a recent industry report, automation in welding processes can improve efficiency by up to 30%. Companies are increasingly adopting automated track welding lathes to meet these demands. This trend reflects a broader shift towards more precise and faster manufacturing processes.

One area of innovation is the integration of artificial intelligence. AI can evaluate the quality of welds in real time, reducing the need for manual inspection. These developments promise to enhance productivity and lower operational costs. Not all companies have adapted to these changes, revealing gaps in technology adoption. Many still rely on traditional lathing methods, proving a need for better training and awareness.

Sustainability also plays a crucial role. Reports suggest that the demand for eco-friendly welding solutions is rising steadily. Manufacturers are exploring materials and processes that minimize waste. However, this transition is not without its challenges. Adopting sustainable practices requires significant investment and research. Companies face the pressure to innovate while managing costs, leading to a complex balancing act.

| Application | Industry | Benefits | Future Trends |

|---|---|---|---|

| Automotive Manufacturing | Automotive | Precision and efficiency | Integration of AI for quality control |

| Aerospace Components | Aerospace | High strength-to-weight ratio | Use of composite materials |

| Railway Manufacturing | Transportation | Durability and reliability | Smart rail technologies |

| Heavy Equipment | Construction | Robust construction | Automation and IoT integration |

| Marine Applications | Marine | Corrosion resistance | Sustainable materials |

| Energy Sector | Energy | Efficiency in production | Focus on renewable energy solutions |

| Oil and Gas Pipelines | Oil and Gas | Structural integrity | Advanced monitoring technologies |

| Construction Machinery | Construction | Heavy-duty performance | Increased automation |

| Telecommunications Infrastructure | Telecommunications | Enhanced connectivity | Smart city integrations |

| Defense Applications | Defense | High precision | Increased use of robotics |