In today's fast-paced manufacturing landscape, "Welding Intelligence" is reshaping traditional practices. This concept goes beyond basic welding techniques. It integrates advanced technologies and data analytics to optimize processes. Manufacturers are leveraging real-time data and intelligent systems to enhance efficiency.

The importance of Welding Intelligence cannot be overstated. Companies struggling with consistency often find that these solutions can elevate their performance. For instance, real-time monitoring adjusts workflows based on immediate feedback. Such adjustments reduce waste and improve overall quality.

However, embracing Welding Intelligence presents challenges. Some organizations face resistance due to the complexity of new systems. This reluctance can hinder progress. It is essential to acknowledge these obstacles and consider how to overcome them. Adopting innovative welding solutions is not just about technology; it requires a shift in mindset and culture within the workforce.

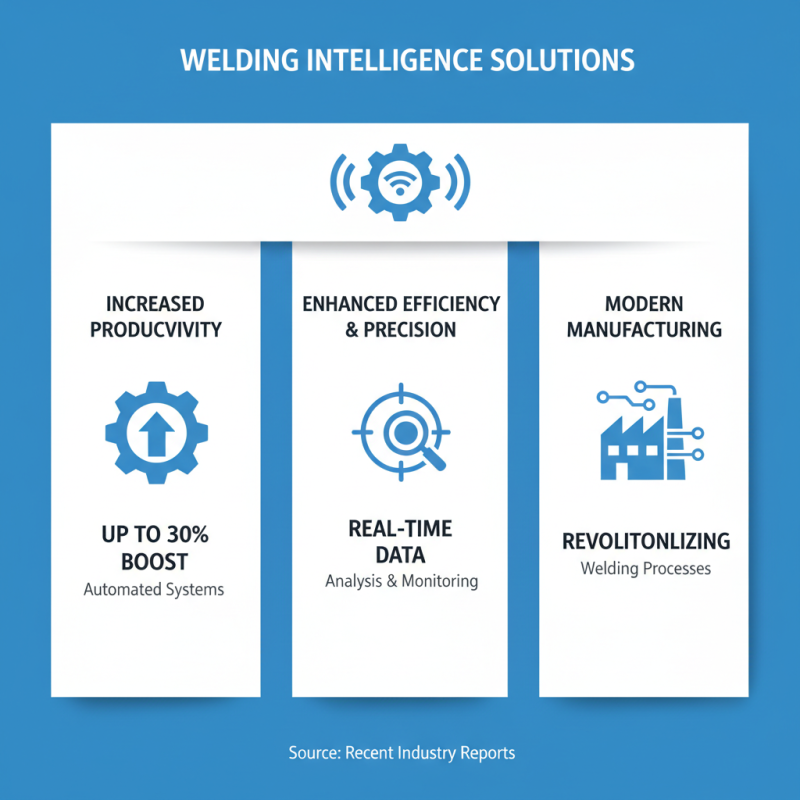

Welding intelligence solutions are revolutionizing modern manufacturing. These technologies enhance efficiency and precision in welding processes. According to recent reports, automated welding systems can boost productivity by up to 30%. This significant increase results from real-time data analysis and monitoring.

Real-time insights allow manufacturers to detect issues early. Problems can be addressed before affecting production. Additionally, welding intelligence solutions improve safety. A significant percentage of workplace incidents are related to welding. With advanced monitoring, those risks can be minimized. In fact, some studies suggest that implementing these solutions can reduce accidents by 25%.

Tips: Invest in training for your workforce. Understanding these technologies is crucial for optimal use. Also, always review your data analytics regularly. It helps identify patterns and optimize processes. Reflect on your current systems and consider upgrades. Even small changes may lead to meaningful improvements. Enhancing your welding operations is an ongoing journey. Identifying weaknesses can lead to better outcomes in the long run.

Welding intelligence solutions have become essential in modern manufacturing. These technologies provide valuable insights that enhance productivity and quality. An effective welding intelligence system collects data in real-time. This allows manufacturers to monitor processes closely. High-quality sensors play a crucial role. They detect variations in temperature and pressure, ensuring consistent performances.

Another key feature is analytics capabilities. Advanced software can analyze welding patterns and flag inconsistencies. This helps in identifying potential issues before they escalate. Predictive maintenance alerts prevent costly downtime. However, relying solely on data isn’t the answer. Human expertise is still necessary to interpret findings correctly.

Moreover, integration with existing manufacturing systems is vital. Seamless data sharing can reduce delays. Yet, many companies struggle with this integration. Often, outdated equipment hinders progress. Effective training for staff is essential to maximize these technologies. Without proper knowledge, employees may misinterpret data, leading to errors. Balancing technology and human skills is the real challenge.

Implementing welding intelligence in manufacturing processes offers significant advantages. A report from the American Welding Society suggests that companies adopting smart welding technologies can reduce costs by up to 30%. This is achieved through improved welding quality and decreased rework.

Efficiency is another crucial benefit. Data indicates that companies can increase productivity by 20% when integrating automated welding solutions. Machine learning algorithms analyze real-time data, optimizing welding parameters. This technology allows teams to adjust processes on the fly, minimizing errors. However, integrating these systems is not always seamless.

Training staff to use new technologies presents challenges. Many workers may feel overwhelmed or resistant. A study by the National Institute of Standards and Technology found that 40% of manufacturers cited workforce adaptation as a significant hurdle. Addressing these issues requires continuous support and open communication. Embracing welding intelligence fosters innovation but also demands a cultural shift within organizations.

Welding intelligence solutions are transforming the manufacturing landscape. Recent industry reports indicate that by 2025, the market for welding intelligence is expected to grow significantly, potentially reaching over $2 billion. The uptake of data-driven insights aids manufacturers in enhancing efficiency. Accurate monitoring of welding processes helps reduce defects and improve product quality.

Top providers in this field are focusing on real-time data collection and analysis. The integration of sensors and AI creates smarter welding systems. These solutions can detect anomalies immediately, improving response times. However, many companies still struggle to implement these technologies effectively. Budget constraints and workforce training are common hurdles.

Investing in welding intelligence is not merely an option but a necessity. A report by a well-regarded industry analyst highlights that manufacturers adopting these systems can see up to a 30% reduction in operational costs. Still, some organizations remain hesitant. They often question the return on investment and the complexity of transition. Such concerns highlight the need for ongoing education and support in this evolving field.

As manufacturing evolves, welding intelligence plays a crucial role. New technologies optimize processes, leading to increased efficiency and reduced costs. Reports show that smart welding solutions can improve productivity by up to 30%. This data highlights the potential for advanced processes in the industry.

Emerging trends focus on real-time data analysis and machine learning. Such technologies enhance quality control and predict equipment failures. For instance, predictive analytics can reduce downtime by 15%. However, integrating these solutions can be challenging. Many manufacturers still struggle with legacy systems that hinder progress.

Moreover, workforce training is essential. Many operators lack the skills needed for smart technologies. A recent survey found that over 50% of manufacturers report a skills gap in their workforce. Addressing this gap is critical for fully leveraging welding intelligence. The future of manufacturing hinges on these factors. Adjustments are needed, and learning from missteps is vital for success.

| Solution | Key Features | Benefits | Expected Trends |

|---|---|---|---|

| Automated Welding Monitoring | Real-time data collection, Process optimization | Increased weld quality, Reduced rework | AI integration, Predictive analytics |

| Robotic Welding Systems | High precision, Speed and Efficiency | Lower labor costs, Consistency in production | Collaborative robots, Increased flexibility |

| Cloud-Based Welding Data Management | Centralized access, Data analysis tools | Enhanced decision-making, Scalability | Enhanced cybersecurity, Remote access |

| Welding Simulation Software | Virtual testing, Process validation | Cost-effective prototyping, Risk mitigation | Integration with AR/VR technology |

| Smart Sensors for Welding | Data collection, Environmental monitoring | Improved safety, Enhanced quality control | Internet of Things (IoT) expansion |

| AI-Driven Process Control | Machine learning algorithms, Adaptive control | Optimized resources, Reduced waste | Increasing automation, AI advancements |

| Augmented Reality for Training | Interactive training, Real-time feedback | Enhanced learning curve, Reduced training time | Widespread adoption in training programs |

| Data Analytics for Welding Performance | Performance metrics, Historical data analysis | Informed strategic decisions, Continuous improvement | Emphasis on data-driven strategies |

| Welding Equipment Diagnostics | Predictive maintenance, Performance tracking | Minimized downtime, Increased efficiency | Integration of AI in diagnostics |

| Virtual Reality for Design and Planning | 3D modeling, Collaborative design | Faster project turnaround, Improved creativity | Expansion in design industries |