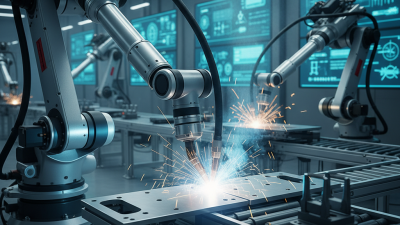

In the world of welding, efficiency and precision are key. A Trackless Weld Cart is a revolutionary tool designed to enhance these very aspects. This innovative cart eliminates the need for tracks, allowing for greater maneuverability on the shop floor. It works using advanced technology that enables it to navigate complex environments with ease.

The Trackless Weld Cart is not just about mobility. It provides stability and support for welding operations, ensuring that the welder can focus on quality. Imagine a workshop where cables are less of a hazard. This cart helps reduce risks and increases productivity in welding tasks. However, it does require training to operate effectively.

While the benefits are clear, there are aspects to consider. Users need to understand its limitations and maintenance needs. Regular checks are crucial to ensure optimal performance. Overall, the Trackless Weld Cart represents a significant advancement in welding technology, inviting both excitement and careful consideration in its usage.

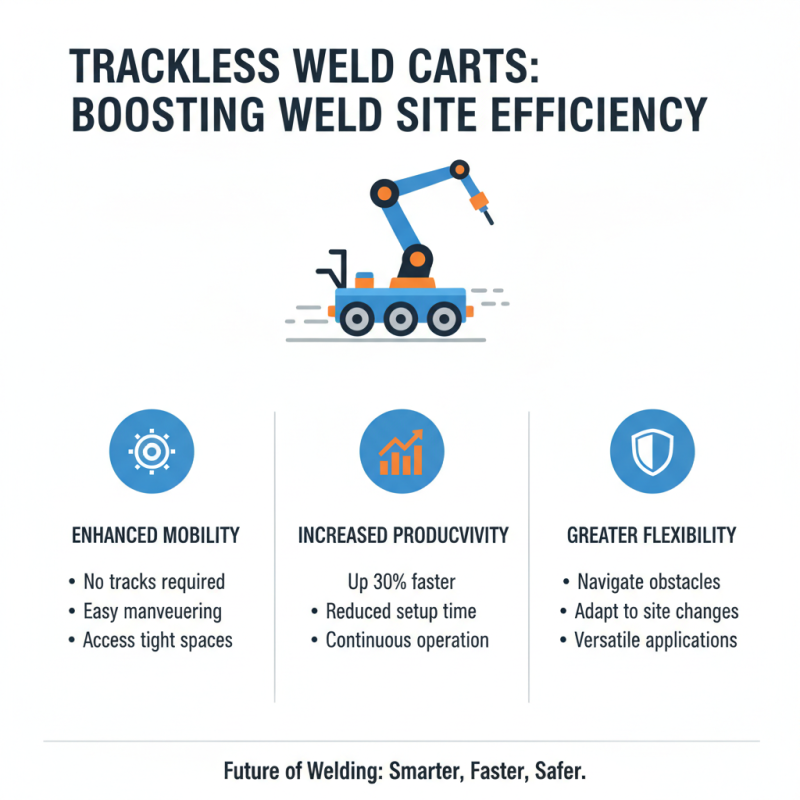

A trackless weld cart is a mobile welding solution that enhances efficiency on job sites. Unlike traditional carts, it operates without a fixed track. This flexibility allows workers to navigate around obstacles easily. According to industry reports, the usage of trackless weld carts can boost productivity by up to 30%. They enable welding in confined spaces and uneven terrains, making them ideal for construction and manufacturing.

Trackless weld carts typically feature advanced technology like remote controls and automated systems. Many models can carry loads of several hundred pounds while maneuvering smoothly. However, not all carts are created equal. Some users report issues with battery life and power management. Regular maintenance is crucial to ensure optimal performance. It’s essential to weigh the benefits against potential drawbacks like initial costs and learning curves.

These carts also increase safety on work sites. They reduce the risk of accidents associated with traditional carts. Reports indicate a significant decrease in workplace injuries when using modern welding carts. However, operators must be properly trained to leverage all features effectively. This ensures safe and efficient welding operations, but training often requires additional time and resources.

A trackless weld cart is an innovative solution in the welding industry. It streamlines the welding process, making it more efficient and portable. The key components of a trackless weld cart include the chassis, power supply, and welding equipment mount. The chassis offers stability and allows easy maneuvering in tight spaces.

The power supply is critical. Many trackless weld carts utilize lithium-ion batteries, which have a 30% longer lifespan compared to traditional battery types. This results in less downtime and increased productivity. With downtime accounting for nearly 20% of a welder's time, improvements in power management can lead to significant efficiency gains.

Welding equipment mounts secure the tools needed for various tasks. Adjustable mounts accommodate different welding machines. This flexibility is vital as jobs vary in size and complexity. A well-designed cart allows for quick adjustments. The average welder spends up to 25% of their time setting up equipment; hence a versatile cart can save time. Users must consider the cart’s weight capacity and dimensions. Not all carts handle heavy equipment well. Each detail matters in ensuring a smooth welding process.

| Component | Description | Function |

|---|---|---|

| Frame | The structural base of the cart that supports all components. | Provides stability and support for welding operations. |

| Control System | Electronic system used to control the welding process. | Ensures precise operation and safety during welding. |

| Power Supply | Source of energy for the welding equipment. | Powers the welding machine for operation. |

| Welding Torch | Tool that delivers heat to melt and fuse materials. | Essential for performing the welding task. |

| Mobility Features | Components that ensure easy movement without tracks. | Allow the cart to navigate various terrains. |

Trackless weld carts represent a significant advancement in welding technology. These innovative devices operate without the need for traditional tracks. Instead, they rely on advanced navigation systems. This allows for increased mobility and flexibility during welding tasks. Operators can easily adjust their positions as needed. This adaptability is especially useful in complex job sites.

The functionality of trackless weld carts hinges on their integrated sensors. These sensors detect the surroundings and adjust movements accordingly. This means the cart can navigate various terrains with ease. Welders can focus on their tasks without worrying about the cart getting stuck. However, this technology isn't perfect. Sometimes, the sensors may misinterpret objects or obstacles. This can lead to unexpected halts in the welding process. Regular calibration of the sensors is essential to ensure optimal performance.

Battery life plays a crucial role in the efficiency of trackless weld carts. Extended periods of use can drain the battery quickly, leading to interrupted workflows. Operators must monitor battery levels closely. It’s important to recharge or replace batteries when necessary. In some instances, workers feel anxious about the cart's reliability during critical tasks. Hence, an awareness of the cart’s capabilities and limitations is vital for a smooth welding operation.

Trackless weld carts offer several advantages over traditional welding methods. They are designed to enhance mobility and efficiency on welding sites. According to a recent industry report, using trackless carts can increase productivity by up to 30% compared to conventional setups. Their flexibility allows for easy maneuvering around obstacles, allowing operators to work in tighter spaces.

One of the significant benefits of trackless weld carts is reduced setup time. Traditional welding requires extensive groundwork and establishing tracks. This can lead to delays and increased labor costs. Trackless systems minimize these issues, enabling faster transitions between welding tasks. Moreover, the design is lightweight and easy to handle, making it user-friendly for welders of all skill levels.

Despite their many benefits, there are considerations to keep in mind. Trackless weld carts may not perform as well in highly complex welding environments. In such cases, the lack of fixed rails could affect precision. Operators might face a learning curve when transitioning from standard methods. These points highlight the importance of evaluating specific needs before making a switch.

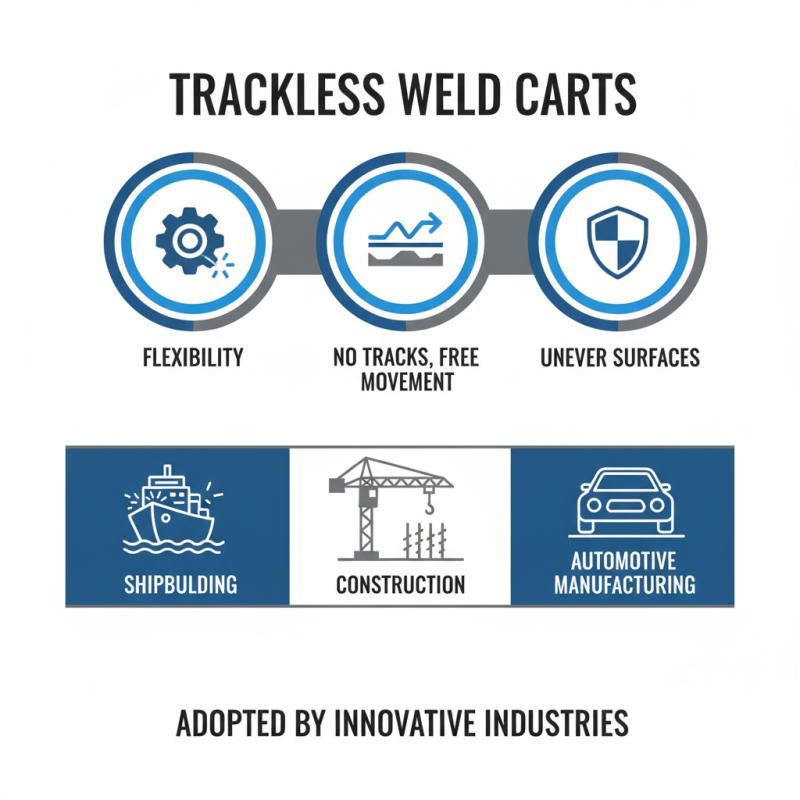

Trackless weld carts offer flexibility in various industrial applications. These carts eliminate tracks, allowing free movement across uneven surfaces. Industries such as shipbuilding, construction, and automotive manufacturing increasingly adopt them.

In shipbuilding, for instance, the large structures often require precise welding in cramped spaces. According to industry reports, the efficiency of welding operations can increase by up to 30% with more mobility. This adaptability addresses challenges in confined areas. However, some users have reported difficulty in achieving stability during operation. Therefore, enhancements are necessary to balance mobility and precision.

Similarly, in the automotive sector, trackless weld carts simplify the assembly of complex parts. They enable quick adjustments, which is vital for production lines. A study indicated that lean manufacturing practices benefit from these carts, reducing downtime by 15%. While they offer speed, some operators struggle with load weight distribution. This inconsistency can lead to mishaps if not regularly assessed.