The Trackless Weld Cart is revolutionizing the welding industry. Its design eliminates tracks, providing seamless mobility for welding tasks. This cart is compact and efficient, allowing operators to work in tight spaces.

Using a Trackless Weld Cart can enhance productivity. It offers flexibility and ease of movement without getting stuck. Operators can maneuver it quickly around obstacles, which saves time. Yet, there may be limitations in some environments. The cart's battery life can also affect performance.

On the technical side, understanding how it works is crucial. The cart uses advanced technology for navigation. This innovation may still need refinement for optimal results. Despite its advantages, users should be aware of potential challenges. It is essential to reflect on these aspects for better usage.

A trackless weld cart is a specialized tool used in welding operations. Unlike traditional carts that rely on tracks for mobility, trackless weld carts are designed for flexibility and ease of movement. They come equipped with advanced maneuverability features, allowing them to navigate tight spaces efficiently. These carts eliminate the constraints imposed by tracks, making them ideal for various welding environments.

One of the main benefits of using a trackless weld cart is its versatility. Users can easily adjust the placement of equipment, ensuring that everything is within reach during the welding process. However, this flexibility can lead to disorganization if not managed properly. Keeping a tidy workspace is crucial to maintain efficiency.

**Tip:** Create a checklist before starting your work. This can help you organize tools and materials effectively.

When using a trackless weld cart, pay attention to the weight distribution. Improper loading can cause the cart to tip over, posing risks to safety. Be mindful of how equipment is arranged.

**Tip:** Regularly check the cart's wheels and brakes. This prevents unexpected breakdowns during crucial tasks.

In summary, a trackless weld cart is a handy tool for welders. Its design allows for improved functionality but requires careful usage to ensure safety and efficiency.

Trackless weld carts are innovative tools in the welding industry. They offer a unique approach to transporting welding equipment. Understanding their key components can enhance their effectiveness.

One of the main components of a trackless weld cart is the frame. It must be sturdy yet lightweight. A well-designed frame allows for easy maneuverability. Wheels should be durable and smooth-rolling. This makes transporting heavy equipment simple. Consider the material of the wheels. Rubber wheels are quieter than metal ones.

Another essential part is the control system. This may include joystick controls or fixed buttons. The controls should be easy to understand and operate. However, some users find them unintuitive at first. Testing different configurations can help you find the best setup.

Tips: When using a trackless weld cart, practice navigating in open spaces first. This helps build confidence before moving on to congested areas. Regular maintenance is crucial. Inspect wheels and control systems frequently to ensure smooth function.

Also, consider the weight distribution. An unbalanced load can lead to accidents. Adjustments may be necessary to avoid these issues. Trackless weld carts can greatly improve efficiency, but they require careful handling.

| Component | Description | Function | Materials Used |

|---|---|---|---|

| Frame | The structure that supports all components. | Provides stability and durability. | Steel or aluminum. |

| Power Supply | Source of electrical energy for welding tasks. | Powers the welding machine. | Electric batteries or power cables. |

| Welding Machine | The main tool used for welding processes. | Joins metal parts together. | Various welding technologies (MIG, TIG, Stick). |

| Control System | Interface for operators to manage the cart. | Enables user control over welding parameters. | Electronic circuits and software. |

| Safety Features | Components designed to ensure operator safety. | Prevents accidents and injuries during operation. | Sensors, emergency stop buttons, protective covers. |

Trackless weld carts are changing the way welding operations are performed. These carts eliminate traditional tracks, allowing for greater flexibility. Welders can easily move equipment around a workspace without constraints. This mobility is especially beneficial in complex environments.

One major advantage of using trackless weld carts is their efficiency. They can navigate tight spaces where track systems may falter. This design leads to faster setup times and less frustration. However, some operators might find them tricky at first. Adjusting to a new way of moving equipment can require patience.

Another benefit is reduced wear on surfaces. Trackless systems don’t leave marks or damage floors. This keeps workspaces cleaner and more professional. Still, the initial investment in trackless technology might deter some. It's important to weigh the long-term savings against upfront costs. Adopting new tools can always be a challenge, but the benefits often outweigh the hesitations.

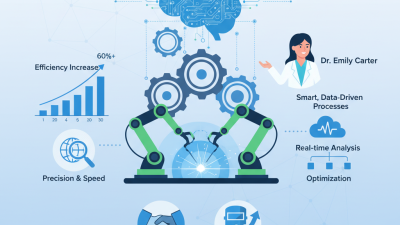

Trackless weld carts are innovative tools designed to improve welding operations. These carts don’t rely on tracks, which allows them to move smoothly across various surfaces. They utilize advanced motion technology to navigate, making them versatile for different work environments. The movement is often guided by sensors that help maintain a consistent path. This ability to maneuver freely enhances productivity in welding tasks.

In terms of functionality, trackless weld carts often feature an automated system. This system ensures precision in positioning for welds, minimizing human error. Operators can set the parameters for welding without needing extensive manual control. However, there can be challenges. For instance, miscalibration can lead to inconsistent welds. Regular checks are needed to ensure sensors and settings are accurate. While these carts provide benefits, adapting to their operation can require adjustment, especially for those accustomed to traditional setups.

Trackless weld carts have gained popularity in various industries. These tools simplify the welding process by moving seamlessly across the shop floor. They are especially useful in environments with tight spaces or complex layouts. Companies that rely on welding often see increased efficiency when using these carts.

In manufacturing, automotive, and construction, trackless weld carts play a crucial role. They help equipment easily maneuver around objects. This flexibility boosts productivity and reduces downtime. Usage statistics show that companies adopting these carts report up to a 30% increase in workflow efficiency. However, not all teams can maximize their benefits initially.

Some operators may take time to adjust. Training is essential for safe and effective use. Miscommunication can lead to accidents. Thus, companies must prioritize proper training. Despite the advantages, occasional equipment failures can occur. Regular maintenance is needed to ensure reliability. These factors remind us that while trackless weld carts offer many benefits, their use requires careful planning and consideration.