In the realm of industrial manufacturing, the Swing Welding Lathe stands out as a pivotal tool that revolutionizes the welding process. Understanding the mechanisms behind this innovative equipment is essential for engineers and operators alike, as it not only enhances precision in welding tasks but also significantly improves overall efficiency.

Swing Welding Lathes operate by rotating the workpiece while simultaneously applying the welding technique, allowing for intricate designs and robust welds that are crucial for a variety of applications. This blog will delve into the fundamental principles governing the operation of Swing Welding Lathes, exploring their design, functionality, and the unique advantages they offer in various industrial contexts. By grasping these concepts, professionals can optimize their welding processes and harness the full potential of this remarkable machinery.

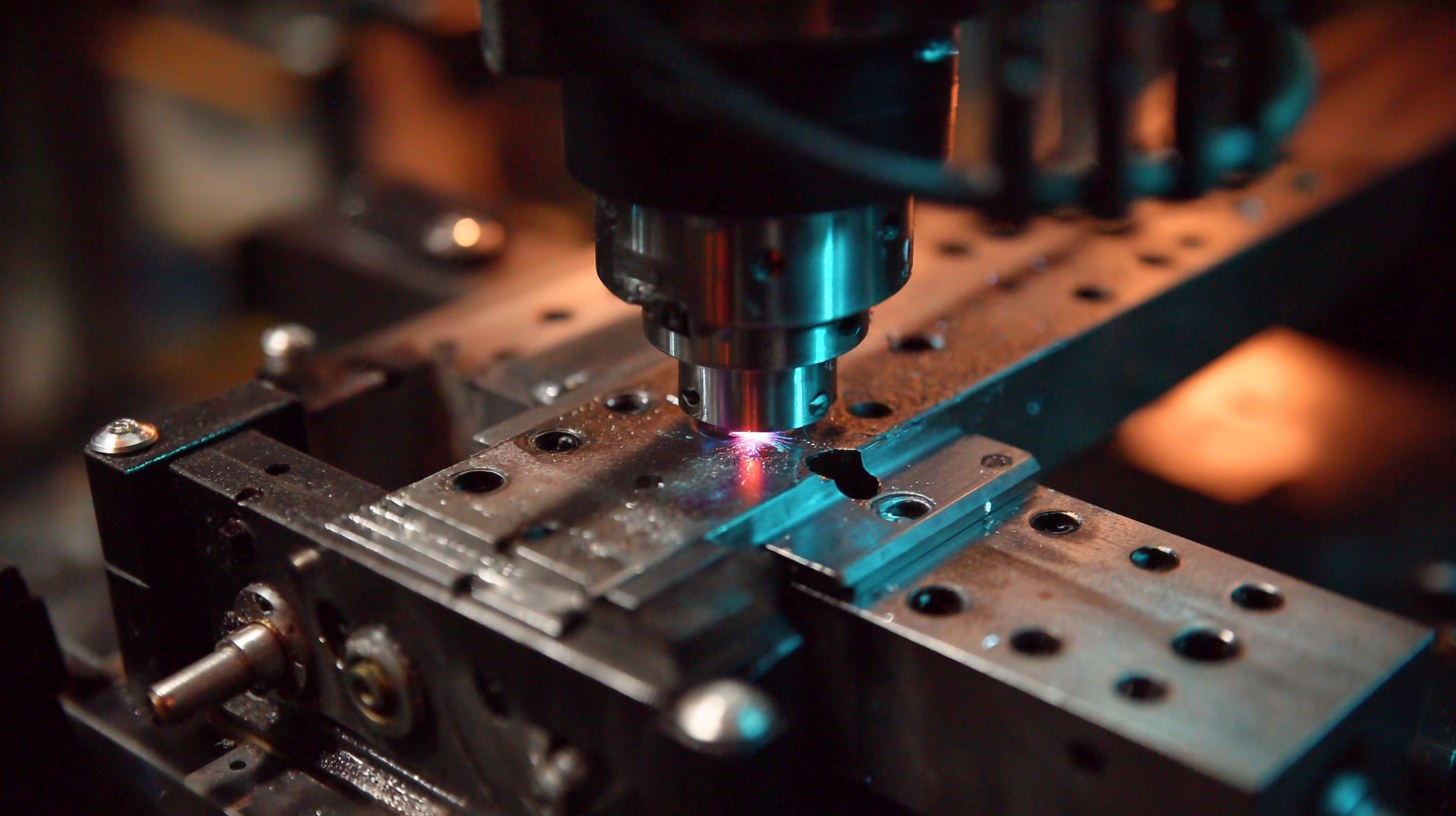

Swing welding lathes are essential tools in modern metal fabrication, offering versatility and precision for various welding tasks. At the heart of these machines lie several key components that contribute to their functionality. One of the primary elements is the rotating head, which allows welders to access intricate angles and positions. This capability is particularly beneficial when working on larger components, as it minimizes the need for repositioning the workpiece, thus increasing efficiency.

Another crucial aspect of swing welding lathes is the drive system, which ensures consistent and controllable operation. This system not only influences the speed of welding but also determines the force applied during operation. Coupled with a sturdy frame, the durability and stability of the machine are maintained, enabling welders to execute precise welds without compromising quality. In a well-organized workshop, such as a farm shop with all major tools and parts storage placed strategically, the swing welding lathe becomes a pivotal element in driving productivity on projects, whether it's crafting agricultural equipment or performing repairs.

Swing welding lathes are an integral part of the modern manufacturing landscape, particularly within industries focused on metal fabrication and automotive component production. The operation of swing lathes revolves around a unique mechanism that allows for precise and controlled welding of cylindrical components. According to a report from the Welding Equipment Manufacturers Committee (WEMC), these lathes can achieve welding speeds of up to 15 inches per minute, which significantly enhances productivity while maintaining high-quality weld integrity.

The science behind swing lathes involves a combination of mechanical engineering and advanced welding techniques. Utilizing CNC (Computer Numerical Control) technology, these lathes can execute complex welding patterns with remarkable accuracy. A study published in the Journal of Manufacturing Science and Engineering notes that CNC-controlled welding processes reduce human error and increase repeatability to over 90%, leading to narrower tolerances and less material waste. This level of precision not only improves production efficiency but also ensures that the end product meets stringent industry standards.

Additionally, advancements in materials science have led to the development of more sophisticated welding wires and techniques, further enhancing the capabilities of swing welding lathes. According to a 2022 market analysis by Research and Markets, the global demand for swing lathes is projected to increase by 12% annually due to their versatile applications and the growing need for high-strength, low-weight welds in industries such as aerospace and renewable energy.

The manufacturing industry has seen significant advancements with the introduction of swing welding lathes, which offer a unique set of advantages for both efficiency and precision. According to a report from the International Welding Institute, the use of advanced welding technologies, including swing welding lathes, can increase productivity by up to 30% compared to traditional welding methods. This boost in efficiency is largely due to the ability of swing welding lathes to handle larger workpieces with greater stability, reducing the risk of defects and minimizing the need for rework.

Moreover, swing welding lathes provide enhanced versatility in manufacturing processes. As noted in a study published by the American Welding Society, manufacturers utilizing swing welding technology report a 25% reduction in cycle times for complex assemblies. This is particularly beneficial in industries such as automotive and aerospace, where precision and quick turnaround are crucial. By adopting swing welding lathes, companies can respond more rapidly to market demands while maintaining high-quality standards, ensuring they remain competitive in an ever-evolving landscape.

Swing welding lathes are essential tools in various industries, primarily due to their versatility in handling complex welding tasks. The automotive and aerospace sectors are two notable fields that extensively utilize swing welding lathes. According to a report by MarketsandMarkets, the global welding equipment market is projected to reach USD 40.0 billion by 2027, driven in part by the high demand for efficient and precise manufacturing processes in these industries. Swing welding lathes allow manufacturers to weld large components with intricate shapes, making them indispensable for the production of vehicle frames and aircraft components.

In addition to automotive and aerospace, swing welding lathes are widely used in the construction and shipbuilding industries. The ease of setup and the ability to rotate the workpiece significantly reduce production time and improve weld quality. A 2021 report by the International Maritime Organization indicated that the shipbuilding industry is expected to grow at a CAGR of 3.5% from 2021 to 2026, reflecting the increasing importance of advanced welding solutions like swing welding lathes in creating durable and reliable structures. These machines not only enhance efficiency but also contribute to improved safety standards in these industries by ensuring high-quality welds.

When working with swing welding lathes, performance issues can arise, impacting both productivity and the quality of your welds. Proactively addressing these concerns can lead to smoother operation and better results. Here are some troubleshooting tips to help optimize your swing welding lathe performance.

First, always ensure that your lathe is properly calibrated. An improperly aligned lathe can lead to uneven welds and increased wear on components. Regularly check the alignment of the rotating axis and the welding tool bit. If you notice any discrepancies, make the necessary adjustments to maintain consistency in your welding process.

Another common issue is overheating. If your lathe is running too hot, it can cause the welding materials to warp and degrade. Monitor the temperature closely, and consider adding cooling systems or increasing the use of coolant to keep the lathe at optimal operating conditions. Additionally, make sure to inspect the cooling system for any clogs or inefficiencies that could be contributing to excessive heat buildup.