Welding Intelligence is emerging as a transformative force within the manufacturing and construction sectors, fundamentally changing how projects are conceived, executed, and evaluated. As technology evolves, the integration of data analytics, artificial intelligence, and machine learning into welding processes is enabling companies to enhance productivity, reduce costs, and improve quality control. According to Dr. Emily Carter, a leading expert in welding technology, "Welding Intelligence is not just about automation; it's about making informed decisions that drive efficiency and innovation." This perspective underscores the potential of Welding Intelligence to optimize workflows and empower engineers and operators alike.

In a world where precision and reliability are paramount, the adoption of Welding Intelligence can lead to significant breakthroughs. By harnessing real-time data, manufacturers can predict issues before they arise, ensuring consistency and safety throughout the welding process. This ability to preemptively address challenges allows teams to focus on creativity and innovation, rather than merely troubleshooting existing problems. As we explore the facets of Welding Intelligence, it becomes clear that it represents a paradigm shift that can revolutionize projects across various industries, paving the way for smarter, more efficient operations.

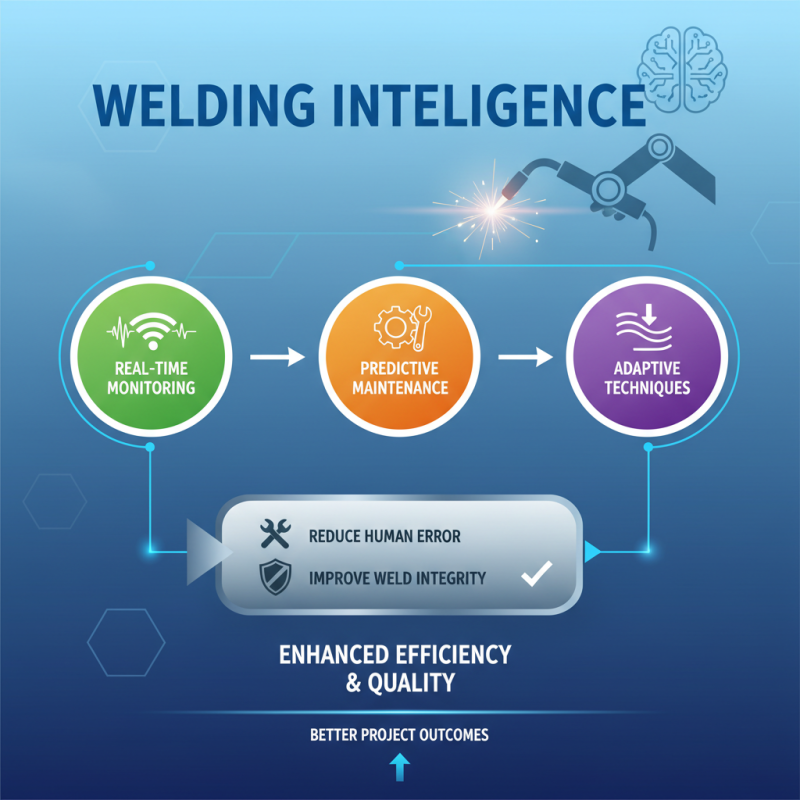

Welding intelligence refers to the integration of advanced technologies such as artificial intelligence (AI), machine learning, and data analytics into the welding process. This amalgamation allows for real-time monitoring, predictive maintenance, and adaptive welding techniques, which altogether enhance efficiency and quality. At its core, welding intelligence transforms traditional welding methods by providing insights that reduce human errors and improve weld integrity, ultimately leading to better project outcomes.

To leverage welding intelligence effectively, consider implementing a robust data collection system that monitors key parameters during welding operations. This could include temperature, pressure, and material behavior. By analyzing this data, welders can predict potential failures before they occur, allowing for timely interventions.

Tips: Always ensure that your equipment is compatible with the latest monitoring technologies for seamless integration. Additionally, encourage training programs that educate your team on interpreting data analytics, which can empower them to make informed decisions on welding processes. Emphasizing a data-driven approach can significantly enhance your project's efficiency and reliability.

The historical development of welding technologies showcases a remarkable evolution from rudimentary techniques to advanced methodologies that have transformed industrial practices. Welding can be traced back to ancient civilizations, with evidence of forge welding techniques utilized by the Egyptians around 1200 B.C. The Industrial Revolution in the 19th century brought significant advances, including the introduction of oxy-fuel welding and arc welding. According to a report by Research and Markets, the global welding market is expected to reach USD 38.96 billion by 2025, demonstrating the increasing reliance on welding technologies in various sectors, including automotive and manufacturing.

Throughout the years, welding technologies have continued to adapt and improve. The emergence of automated welding processes in the mid-20th century, such as Gas Metal Arc Welding (GMAW) and Tungsten Inert Gas (TIG) welding, dramatically enhanced precision and efficiency. The American Welding Society reports that advancements in automation and robotics are projected to be key growth drivers in the coming years, as industries seek to increase productivity while reducing labor costs. These innovations not only elevate the quality of welds but also ensure worker safety and enhance overall project outcomes across numerous applications.

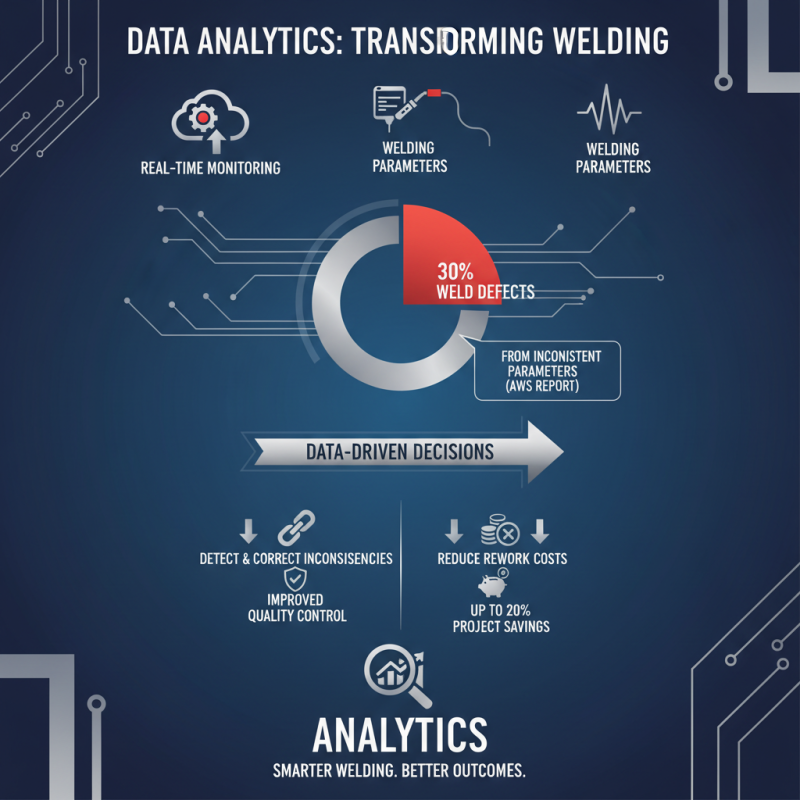

Data analytics is playing a transformative role in the welding industry, fundamentally enhancing welding processes and outcomes. By leveraging advanced data collection methods, companies can monitor real-time welding parameters, which significantly improves quality control. According to a report by the American Welding Society, over 30% of weld defects stem from inconsistent parameters, making data-driven decisions critical. By utilizing data analytics, these inconsistencies can be detected and corrected promptly, leading to a reduction in defects and rework costs, which can account for up to 20% of a fabrication project’s budget.

Moreover, predictive analytics can shift the approach from reactive to proactive welding management. By analyzing historical data alongside current trends, companies can forecast potential failures and maintenance needs before they occur. A study conducted by Grand View Research noted that predictive maintenance can decrease downtime by up to 30%. This not only enhances the efficiency of welding operations but also extends the life of equipment and reduces overall operational costs. Ultimately, by integrating data analytics into their workflows, welding professionals can achieve greater precision and reliability, ensuring that projects are completed on time and within budget.

Welding intelligence is transforming the landscape of manufacturing and construction through enhanced efficiency and precision. One compelling case study comes from a large-scale automotive manufacturer that implemented welding intelligence solutions to improve its production line. By utilizing real-time data analytics and machine learning algorithms, the company was able to reduce welding defects by over 30%. This implementation not only streamlined the workflow but also resulted in a significant decrease in rework costs, estimated at around $2 million annually. Such improvements underscore the potential of welding intelligence to drive operational excellence in high-stakes environments.

Another notable example can be seen in the aerospace industry, where a leading manufacturer adopted welding intelligence systems to monitor and optimize their welding processes. By integrating IoT sensors into their equipment, they achieved unprecedented levels of data collection, enabling predictive maintenance. As a result, the company reported a 25% increase in equipment uptime. Furthermore, a report by the American Welding Society highlighted that such advancements could contribute to a 15-20% reduction in production timelines, allowing companies to meet tight project deadlines without compromising quality. These case studies illustrate that welding intelligence not only enhances technical capabilities but also delivers significant financial benefits, making it a pivotal element in modern industrial practices.

Predictive maintenance and automation are poised to transform the landscape of welding. As technology advances, the implementation of predictive analytics enables operators to anticipate equipment failures before they occur, thus optimizing uptime and extending the lifespan of welding machines. By gathering and analyzing performance data, teams can identify potential issues and schedule maintenance proactively, reducing unexpected downtimes that can stall project timelines. This shift empowers organizations to allocate resources more effectively, ensuring that projects are completed on time and within budget.

Incorporating automation into welding processes further enhances efficiency by streamlining repetitive tasks and enhancing precision. Automated welding systems can operate consistently, reducing variability and improving the quality of outputs. Skilled workers can then focus on more complex operations, where human expertise is essential. This transition not only boosts productivity but also elevates safety, as hazardous duties can be delegated to machines.

Tips for fostering these innovations include investing in training for staff on new technologies and integrating robust data collection systems. Additionally, evaluate existing equipment to identify which tools can benefit from predictive maintenance. Embracing these future trends in welding not only improves operational efficiency but can also lead to significant cost savings and better project outcomes.

| Dimension | Description | Impact on Projects |

|---|---|---|

| Predictive Maintenance | Utilizing data analytics to predict equipment failures before they occur. | Reduces downtime and maintenance costs, increasing overall efficiency. |

| Automation | Implementation of robotic welding and automated processes to enhance production. | Improves precision, consistency, and speed of welding operations. |

| Data Integration | Consolidating various data sources for comprehensive analysis. | Allows for better decision-making and resource allocation in projects. |

| Real-time Monitoring | Continuous tracking of welding conditions, parameters, and quality. | Enhances quality control and reduces the risk of defects in welds. |

| Skill Enhancement | Training programs to upskill workers in advanced welding technologies. | Increases workforce competency and productivity in welding tasks. |