Welding Intelligence is becoming crucial for modern manufacturing. According to the Industry 4.0 report, over 60% of manufacturers report increased efficiency through advanced welding technologies. This data reflects a broader trend in the sector. The demand for precision and speed drives innovation in welding processes.

Expert in the field, Dr. Emily Carter, states, "Welding Intelligence transforms traditional methods into smart, data-driven processes." Her insights highlight the shift towards integrating technology. Companies now analyze data in real-time to optimize welding operations. This shift not only enhances productivity, but it also raises questions about workforce adaptation.

Welding Intelligence is not without its challenges. Many workers may struggle with new technologies. Balancing human skills with automation remains a concern. However, neglecting this trend could mean falling behind competitors. The future of manufacturing hinges on embracing intelligent welding solutions.

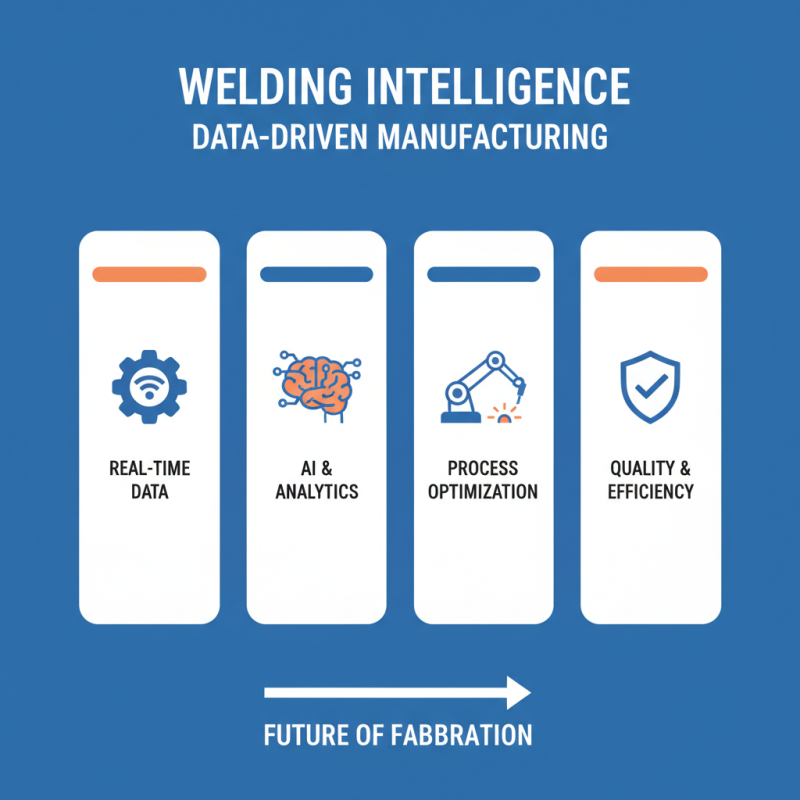

Welding intelligence plays a critical role in today's manufacturing landscape. This concept revolves around the integration of data analytics and artificial intelligence into traditional welding processes. By harnessing real-time data, manufacturers can enhance their welding techniques, improving both efficiency and quality.

Imagine a scenario where sensors monitor temperatures and material properties during a weld. This data can be analyzed instantly to adjust parameters on the fly. However, not all data is useful. Identifying key metrics takes time and experience. Additionally, the complexity of managing vast amounts of information often overwhelms teams.

The shift towards welding intelligence isn't perfect. Some manufacturers may struggle with technological integration. Others may face resistance from employees reluctant to adopt new methods. These challenges remind us that progress requires patience and adaptability. Embracing welding intelligence means accepting a learning curve.

In modern manufacturing, welding processes are becoming increasingly complex. The integration of data analytics is transforming how industries approach welding. By analyzing variables such as temperature, pressure, and arc length, manufacturers can optimize their welding techniques. This leads to improved efficiency and reduced costs.

Tips for leveraging data analytics in welding include monitoring equipment performance in real-time. Regularly assess the data collected to pinpoint inconsistencies. For example, if a particular weld consistently fails, analyzing the data may reveal patterns related to settings or materials. This can help in honing processes that deliver better quality.

Moreover, investing in training for staff can enhance their ability to interpret data analytics. Workers equipped with analytical skills can make better decisions on the shop floor. Sometimes, traditional techniques may not align with new data findings. It's crucial to remain open to adjusting longstanding practices based on these insights. This adaptability is key in the ever-evolving landscape of manufacturing.

Incorporating welding intelligence into production dramatically enhances efficiency. Advanced technologies provide real-time data on welding processes. Operators can monitor temperature, speed, and material quality. This feedback helps in immediate adjustments, preventing defects. Companies can reduce waste significantly.

The integration of smart welding solutions also drives safety improvements. Real-time monitoring ensures adherence to safety protocols. Data analytics can predict potential failures. Fewer accidents mean less downtime and lower costs. However, transitioning to intelligent systems can be challenging. Staff may need training, and there could be resistance to change.

Another notable benefit is the boost in product quality. Data-driven insights lead to more precise welds. Consistency becomes easier to maintain. However, reliance on technology must be balanced. Human oversight is still essential. Understanding the machines’ limitations can prevent over-reliance. Embracing welding intelligence opens up new possibilities for modern manufacturing.

| Benefit | Description | Impact on Production |

|---|---|---|

| Increased Efficiency | Welding intelligence systems streamline workflow and reduce operation time. | Up to 30% faster production rates. |

| Improved Quality Control | Real-time monitoring and adjustments lead to higher quality welds. | Reduction of defects by 25%. |

| Cost Savings | Reduced waste and rework minimize material costs. | Savings of 15% on material costs. |

| Data Analysis | Advanced analytics provide insights into production trends and issues. | Improvement in forecasting accuracy by 40%. |

| Enhanced Worker Safety | Automation of dangerous tasks reduces risks associated with welding. | Decrease in workplace accidents by 50%. |

Welding intelligence plays a crucial role in modern manufacturing. However, implementing this technology poses significant challenges. According to a recent industry report, 70% of manufacturers cite skills gaps as a major barrier. Many welders lack the training to use advanced systems. This issue leads to inefficiencies and decreased productivity on the shop floor.

Data from another source shows that predictive maintenance can reduce downtime by 30%. Yet, only 25% of companies currently utilize this technology. Resistance to change is common. Many workers feel overwhelmed by new processes. This hesitance can slow the adoption of welding intelligence. Training programs need improvement to address these gaps effectively.

Cost is another factor. Some estimates claim companies can save up to 20% by adopting intelligent welding systems. Still, upfront investments can be daunting for smaller operations. There’s a perception that advanced technology is only for larger firms. This mindset can lead to missed opportunities for growth and innovation. Embracing welding intelligence requires a cultural shift within organizations.

The integration of welding technology with intelligence is revolutionizing modern manufacturing. In 2022, the global welding market was valued at $25 billion and is projected to grow by 4% annually. This growth is driven by increased automation and the demand for precision. Advanced welding technologies are increasingly incorporating artificial intelligence (AI) to enhance efficiency and quality.

Real-time data analysis is crucial for today’s production lines. Studies indicate that AI can improve welding accuracy by up to 30%. Intelligent systems monitor welding parameters continuously, reducing defects and rework. However, not all manufacturers are leveraging these technologies. Many still rely on traditional methods, risking quality and productivity.

Workforce training is vital for capitalizing on these advancements. As technology evolves, skilled labor is becoming scarce. A report highlighted that 45% of companies face challenges in finding qualified personnel. This gap in skills raises questions about future competitiveness in the market. Investing in employee education can bridge this divide and encourage innovative practices.