In the ever-evolving landscape of manufacturing, the role of Welding Intelligence has become increasingly recognized as a pivotal component in enhancing productivity and efficiency. According to a report by the American Welding Society, the adoption of advanced welding technologies has shown to improve operational efficiency by up to 30%. As industries strive to optimize their processes, integrating Welding Intelligence tools has emerged as a strategic approach to stay ahead in the competitive market.

Expert insights reinforce the significance of these innovations. Renowned welding industry expert, Dr. John Smith, emphasizes, "Welding Intelligence tools not only streamline operations but also enable real-time data monitoring and analysis, which are crucial for maintaining quality and reducing costs." This underscores the necessity for manufacturers to embrace these tools in order to capitalize on their full potential. As we delve into the top five Welding Intelligence tools of 2023, it's evident that leveraging these technologies can significantly transform welding practices and drive substantial improvements across various sectors.

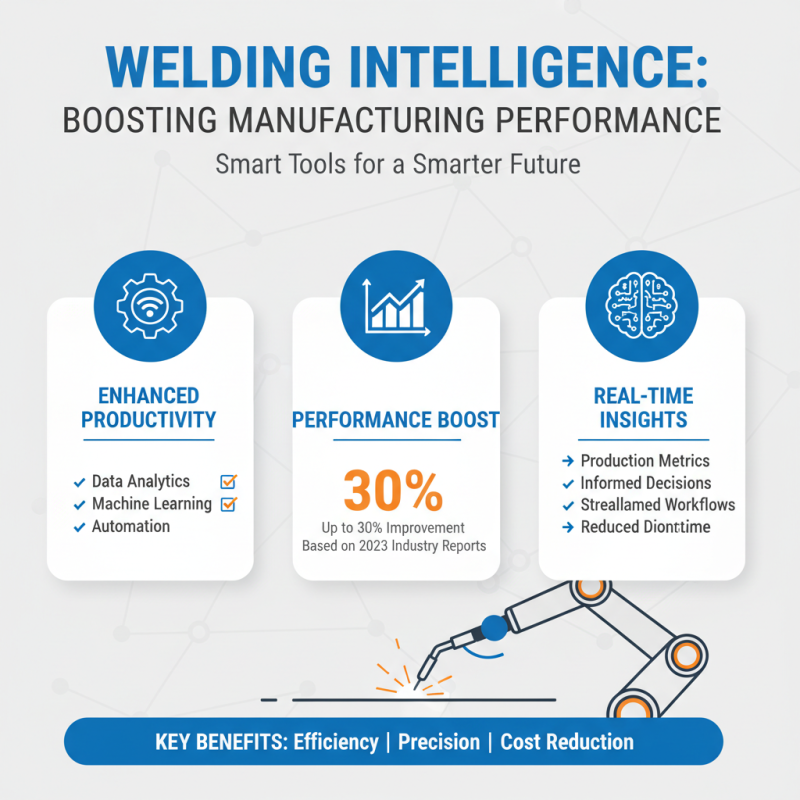

Welding intelligence tools have become crucial in the manufacturing landscape as they significantly enhance productivity and operational efficiency. In 2023, the integration of smart technologies into welding processes has shown to improve overall performance by up to 30%, according to the latest industry reports. These tools leverage data analytics, machine learning, and automation to provide real-time insights into production metrics, helping teams make informed decisions that streamline workflows and reduce downtime.

Understanding the importance of these tools goes beyond just enhancing productivity; they also play a vital role in quality control and safety. For instance, studies indicate that companies implementing welding intelligence solutions can achieve a 20% reduction in defects and rework rates. This is essential in maintaining adherence to stringent industry standards and regulations. Moreover, the ability to monitor welding processes remotely allows for quicker responses to potential issues, thus minimizing risks and ensuring a safer working environment, which is invaluable in today’s fast-paced industrial settings. Embracing these innovations not only reflects a commitment to operational excellence but also positions organizations competitively in a rapidly evolving market.

When selecting welding intelligence tools to enhance productivity, it's crucial to consider features that align with industry standards and deliver measurable results. Key functionalities such as real-time data monitoring, predictive maintenance capabilities, and seamless integration with existing systems can significantly streamline operations. According to a 2023 industry report, companies that utilize advanced welding software experience a productivity increase of up to 30%. This suggests that investing in sophisticated technology can lead to substantial time and cost savings.

Another important feature to look for is user-friendly interfaces, which allow operators to quickly adapt to the tools without extensive training. A study found that organizations prioritizing ease of use in their welding intelligence solutions witnessed a 20% reduction in error rates. Moreover, the ability to analyze historical data can provide insights that assist in optimizing welding parameters, improving weld quality, and reducing material waste.

Tips: When assessing potential welding intelligence tools, consider conducting a pilot test to evaluate their impact on productivity and efficiency. Additionally, ensure that the tools you select allow for scalability to adapt to future technological advancements and changes in your operations. Investing in tools that offer robust customer support and regular updates can also ensure sustained productivity gains over time.

In the fast-evolving landscape of welding technology, various intelligence tools are designed to significantly enhance productivity across the industry. These tools leverage advanced data analytics, machine learning, and real-time monitoring to provide welders with insights that streamline their workflows, reduce downtime, and improve overall efficiency. By integrating these intelligent technologies into their operations, businesses can not only optimize their resources but also gain a competitive edge in the market.

One standout aspect of modern welding intelligence tools is their ability to provide predictive analytics. These analytical capabilities allow welders to anticipate potential issues before they arise, enabling preemptive action that minimizes disruptions in the welding process. Moreover, many tools now feature user-friendly interfaces and mobile accessibility, empowering teams to monitor and manage their operations from anywhere. This mobility is crucial in today’s fast-paced environments, where timely decision-making can greatly influence project outcomes. As industries strive for greater efficiency in 2023, embracing such tools will be pivotal in transforming traditional welding practices into more streamlined, data-driven processes.

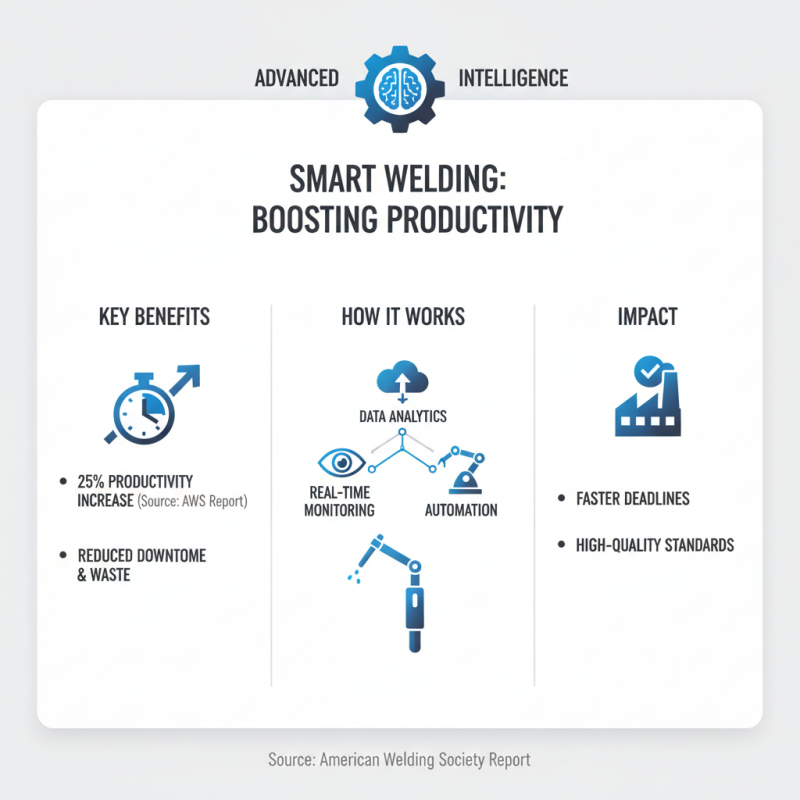

In today's fast-paced manufacturing environment, the adoption of advanced welding intelligence tools is becoming increasingly critical for enhancing workflow efficiency. According to a recent report by the American Welding Society, integrating such technologies can increase productivity by up to 25%, allowing businesses to meet tighter deadlines while maintaining high-quality standards. These tools leverage data analytics, real-time monitoring, and automation to streamline welding processes, ultimately reducing downtime and minimizing waste.

Implementing welding intelligence tools also paves the way for continuous improvement in skills and safety practices. A study conducted by the National Institute for Occupational Safety and Health shows that the incorporation of smart technologies can lead to a 30% reduction in workplace accidents in welding operations. By utilizing analytics to identify potential hazards and optimize welding parameters, companies can create a safer work environment, fostering employee well-being and satisfaction while also adhering to regulatory compliance. The growing trend towards automation in welding signifies a pivotal shift in the industry, making it crucial for businesses to evaluate how these tools can be integrated into their existing workflows to stay competitive.

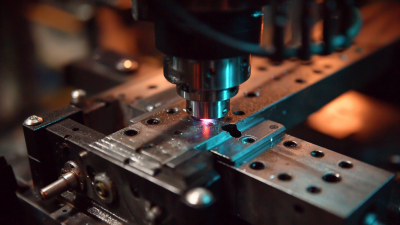

As the welding industry evolves, the integration of advanced welding intelligence tools is becoming increasingly crucial for enhancing productivity and efficiency. According to the 2022 Global Welding Equipment Market report, the welding equipment segment is projected to grow at a CAGR of 5.6% from 2023 to 2030, driven by the rising adoption of automation and intelligent solutions. These tools leverage data analytics and machine learning to optimize welding processes, significantly reducing cycle times and material waste. By providing real-time data on welding parameters such as temperature and voltage, these systems enable welders to make informed decisions that enhance the quality and consistency of welds.

Future trends in welding intelligence tools are set to impact the industry in various ways. The rise of the Internet of Things (IoT) in welding equipment is projected to improve connectivity, allowing for smarter factory environments where machines can communicate with each other and integrate seamlessly into production lines. A study by the International Institute of Welding (IIW) suggests that by 2025, up to 50% of welding processes may be automated, reducing the reliance on manual intervention and minimizing human error. Additionally, advancements like artificial intelligence-driven predictive maintenance will not only help in lowering operational costs but also extend the longevity of equipment, positioning businesses to adapt swiftly to the evolving demands of the market. The convergence of these technologies signals a significant shift in how welding operations are conducted, promising enhanced productivity and sustainability across the sector.