In the modern fabrication and construction sectors, the importance of a reliable Welding Machine Set cannot be overstated. According to the Lincoln Electric Company, the global welding equipment market is projected to reach $24 billion by 2025, highlighting the essential role that effective welding machinery plays in enhancing productivity and safety in workshops. A well-chosen Welding Machine Set not only boosts efficiency but also ensures high-quality welds, which are critical for structural integrity. Moreover, with the rising demand for skilled welders and specialized welding techniques, investing in advanced welding equipment has become imperative for businesses aiming to stay competitive. This blog will explore the key features of a Welding Machine Set, offering tips to help you make informed decisions that can enhance your workshop's capabilities.

Choosing the right welding machine for your workshop is crucial for achieving optimal performance and efficiency in your projects. Each type of welding machine comes with its specific characteristics and capabilities, tailored to different materials and applications. For instance, MIG welders are ideal for beginners and cater to various materials, while TIG welders provide precision for intricate work, making them suitable for professional use. Understanding the unique requirements of your projects will help you select a machine that not only meets your current needs but also allows for potential future expansions.

Additionally, considering factors such as power source, portability, and the thickness of materials you'll be working with can significantly impact your choice. A machine that is too powerful may be overwhelming for smaller tasks, while a less powerful machine could struggle with heavier materials. Therefore, assessing the scale of your projects and the materials you'll frequently work with is essential for selecting the right welding machine. Ultimately, investing time in understanding your workshop needs and the available machines can lead to enhanced productivity and higher quality output in all your welding endeavors.

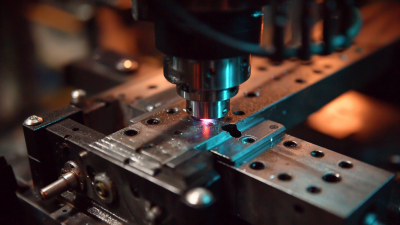

When it comes to setting up a workshop, choosing the right welding machine is crucial. The three most common types of welding machines are MIG, TIG, and Stick, each tailored to specific applications and user skill levels. MIG (Metal Inert Gas) welding is widely appreciated for its ease of use, making it a popular choice for beginners and those seeking quick, efficient welds. It works by continuously feeding a wire electrode through the welding gun, which melts and joins metal pieces together. This method is particularly effective for welding thin materials and is often employed in automotive repair and fabrication projects.

On the other hand, TIG (Tungsten Inert Gas) welding offers more versatility and precision, ideal for detailed work on a variety of metals, including aluminum and stainless steel. TIG welding requires a higher skill level, as the welder manually feeds a filler rod while controlling the arc with a tungsten electrode. This technique provides clean, high-quality welds that are less likely to require additional cleanup. Lastly, Stick welding, also known as Shielded Metal Arc Welding (SMAW), is the most traditional method and is known for its ability to perform well in outdoor conditions and on rusty or dirty materials. Stick welding is highly portable and doesn't require shielding gas, making it a favorite for maintenance and repair work in various environments. Each of these welding machines has its own strengths, and understanding their differences is essential for any workshop owner looking to make informed decisions.

When choosing a welding machine, several key features can significantly enhance efficiency in your workshop. First and foremost, consider the type of welding process you'll be utilizing, whether it's MIG, TIG, or Stick welding. Each process has distinct advantages and is suited for different materials and applications. A versatile machine that supports multiple processes can be a great asset, allowing for adaptability in varied projects.

Additionally, pay attention to the power output and duty cycle of the welding machine. A higher power output enables you to tackle thicker materials, while an appropriate duty cycle ensures that the machine can handle prolonged use without overheating. These factors contribute not only to the quality and strength of the welds but also to the overall productivity of your operations.

In the context of the ongoing transformation in manufacturing, characterized by the rise of collaborative robots, having an efficient welding machine complements the technological advancements and personalized production trends more effectively. This synergy can lead to optimized workflows and improved output.

When selecting welding machines for your workshop, focusing on cost-effectiveness is crucial for long-term operations. Data from the American Welding Society indicates that quality machines can reduce operational costs by up to 30% over their lifespan. High-quality welding machines not only enhance productivity but also minimize the frequency of repairs and maintenance, directly impacting your bottom line.

**Tip:** Invest in machines with proven durability and warranties, as these often indicate a reliable return on investment. Research shows that workshops using top-tier welding equipment experience significantly lower downtime, contributing to a more efficient workflow.

Additionally, the initial investment in a quality welding machine often pays off over time. According to a report from the Institute of Welding, businesses that opt for reputable brands typically see an ROI within three years, due to decreased energy costs and improved welding efficiency.

**Tip:** Always compare the energy consumption ratings of welding machines; higher efficiency can lead to substantial savings on electricity bills. Furthermore, consider machine features that promote ease of use and adaptability, ensuring that your workshop can meet various project demands efficiently.

When it comes to setting up an efficient and safe welding environment in your workshop, adherence to safety standards and compliance is paramount. Welding operations can pose various hazards, making it essential to ensure that all equipment meets established regulations. Properly functioning welding machines not only enhance productivity but also protect workers from accidents and injuries. Compliance with safety standards, such as those outlined by the Occupational Safety and Health Administration (OSHA), helps organizations maintain safe working conditions and minimizes risks associated with welding tasks.

Another crucial aspect is the selection of personal protective equipment (PPE) tailored for the diverse workforce. Designing PPE that accommodates the specific needs of all workers, including proper fitting for women, is vital in promoting comfort and safety. Furthermore, ensuring regular pressure vessel inspections and maintaining compliance with regulatory standards fortifies the safety framework within which welding occurs. By prioritizing these considerations, workshop managers can cultivate a safer working environment while also encouraging productivity and responsibility in their operations, ultimately safeguarding their most valuable asset—their workforce.