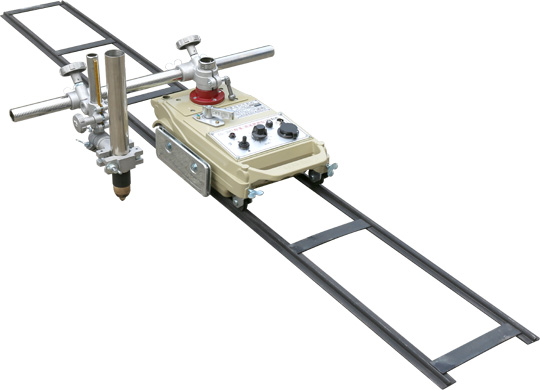

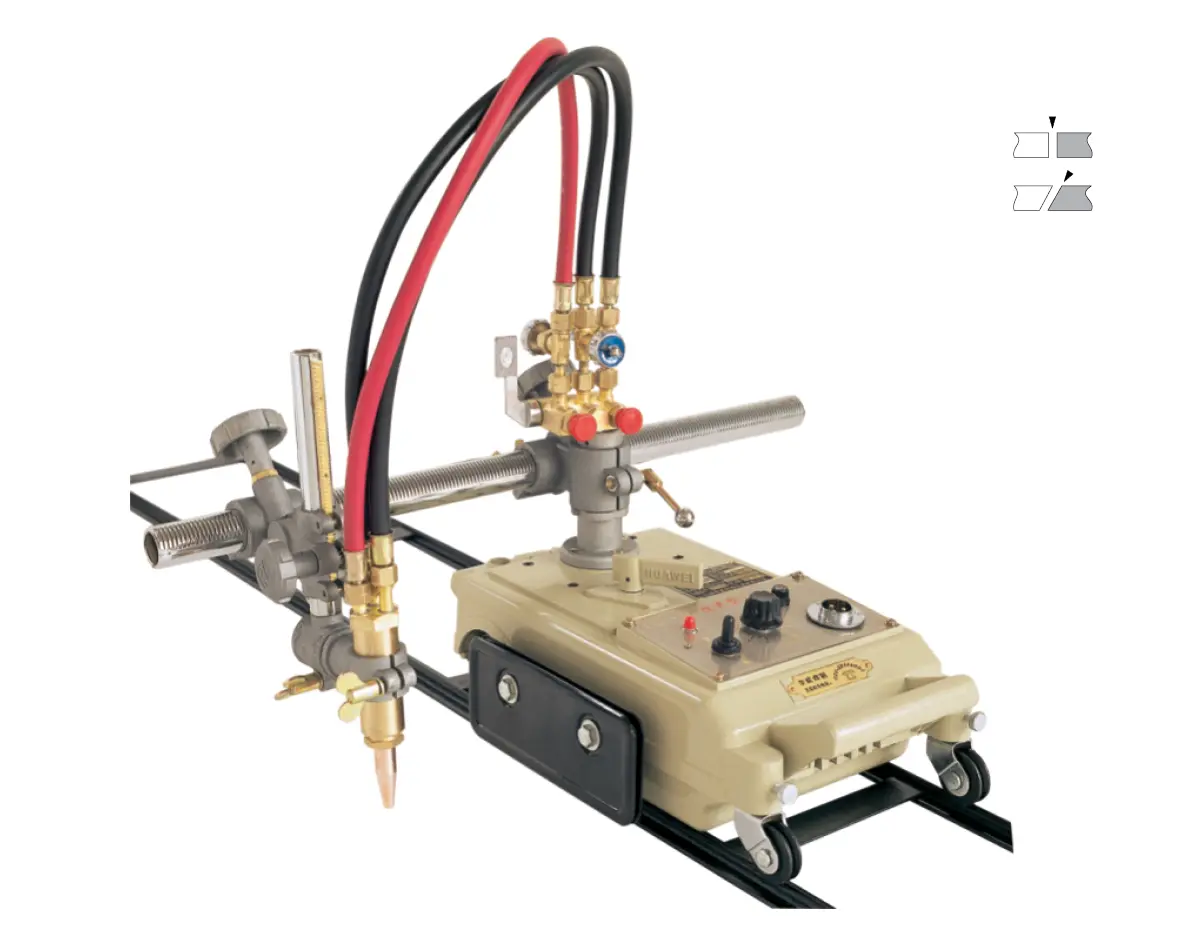

Flame cutting machine

DESCRIPTION

1.Hose:The three hoses are used individually for fuel gas, preheating oxygen and cutting oxygen.

2. Cross hand wheel:To adjust the horizontal distance of torch

3. Cross gear rack

4.Vertical adjusting hand wheel of torch

5.Tip

6.Thermal baffle:To prevent the heat diffusing into the inner of machine.

7. Fuel gas two-port valve:To adjust gas-flow rate.

8. Gas distributor.

9.Clutch hand knob: “STOP” is parting. “START”is combination.

10. Body

11. Speed controller : Increase the speed from “0”to“10”Decease speed from “10” to “0”.

12. Outlet

13. Universal wheel

TECHNICAL SPECIFICATION

|

1.Weight |

:16 kg |

|

Accessory |

:7.8 kg |

|

2. Machine dimension |

:435×210×240mm |

|

3. Speed control |

:silicon control |

|

4. Power source |

:AC 480V±10% 50HZ |

|

5. Cutting speed |

:50~750/mm/min |

|

6. Cutting thickness |

:5-100mm |

|

7.Groove angle |

:0-45° |

|

8.Diameteral of cutting circle |

:ø200-ø2000mm |

|

9.Tip |

:G02(acetylene),G03(propane) |

|

10.Motor |

:DC 110V 50HZ 30W 4200r/min |

4.1 Contents of package

Carefully take the machine out of its case.

The contents of the standard package are shown below. Check them carefully before assembling the machine.

|

1. Body |

1set |

|

2.Torch unit assemblage |

1set |

|

3. Moving unit assemblage |

1set(including left-right, up-down moving unit assemblage and gear rack) |

|

4. Tip (acetylene) |

3pcs |

|

5.Power wire |

1pc |

|

6.Specification sheets and certificate of qualification |

1pc each |

|

7.Gas-in connector /pressure cat |

1set |

|

8.Ball-pane screw M4 |

2pcs |

|

Standard accessory |

|

|

1.Cutting circle unit assemblage |

1set |

|

2.convex guide rail |

2pcs(1.8m/pc)or grooved guide rail 1pc(1.8m) |