POPWELD Automated Welding Positioner

products description

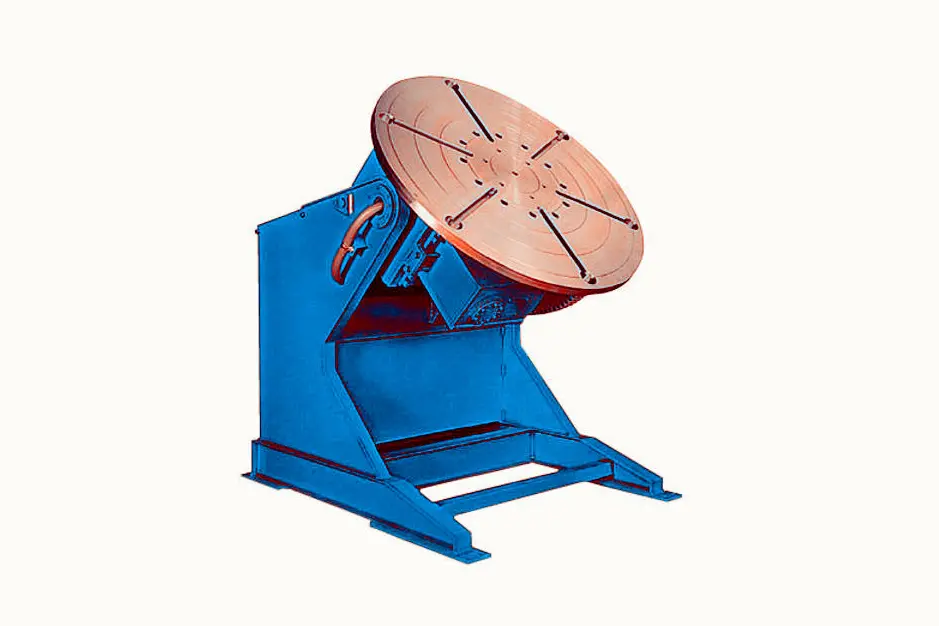

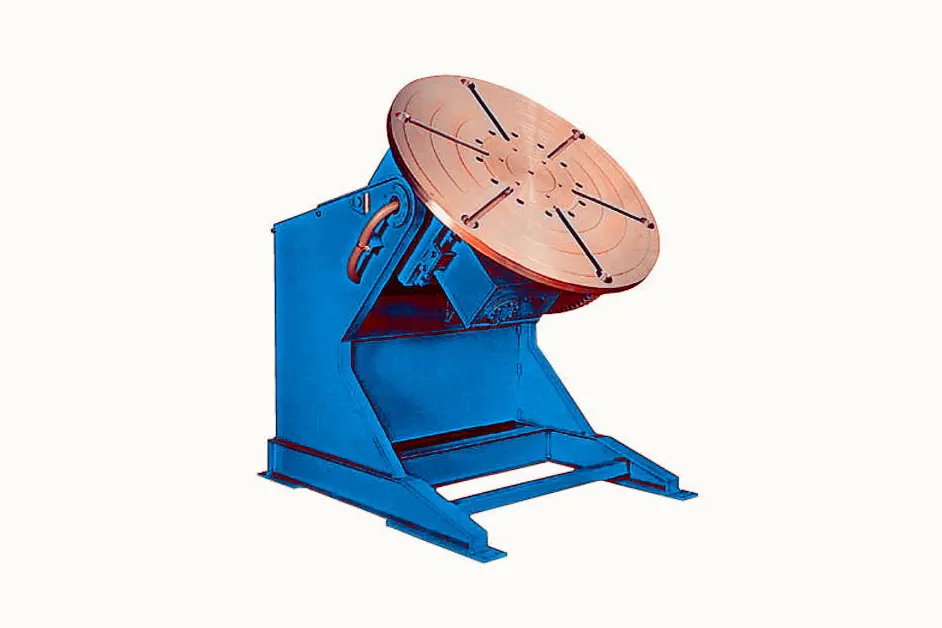

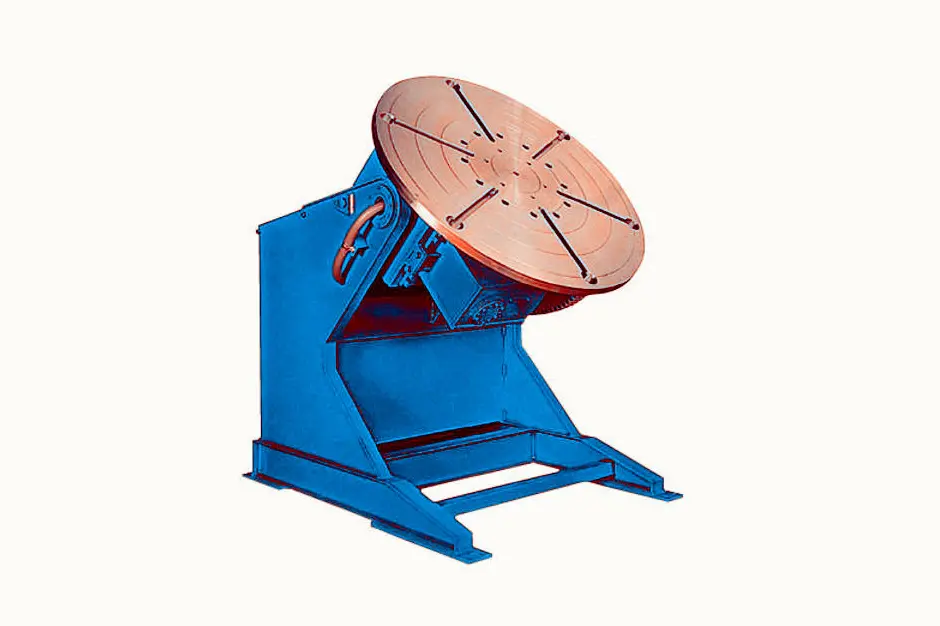

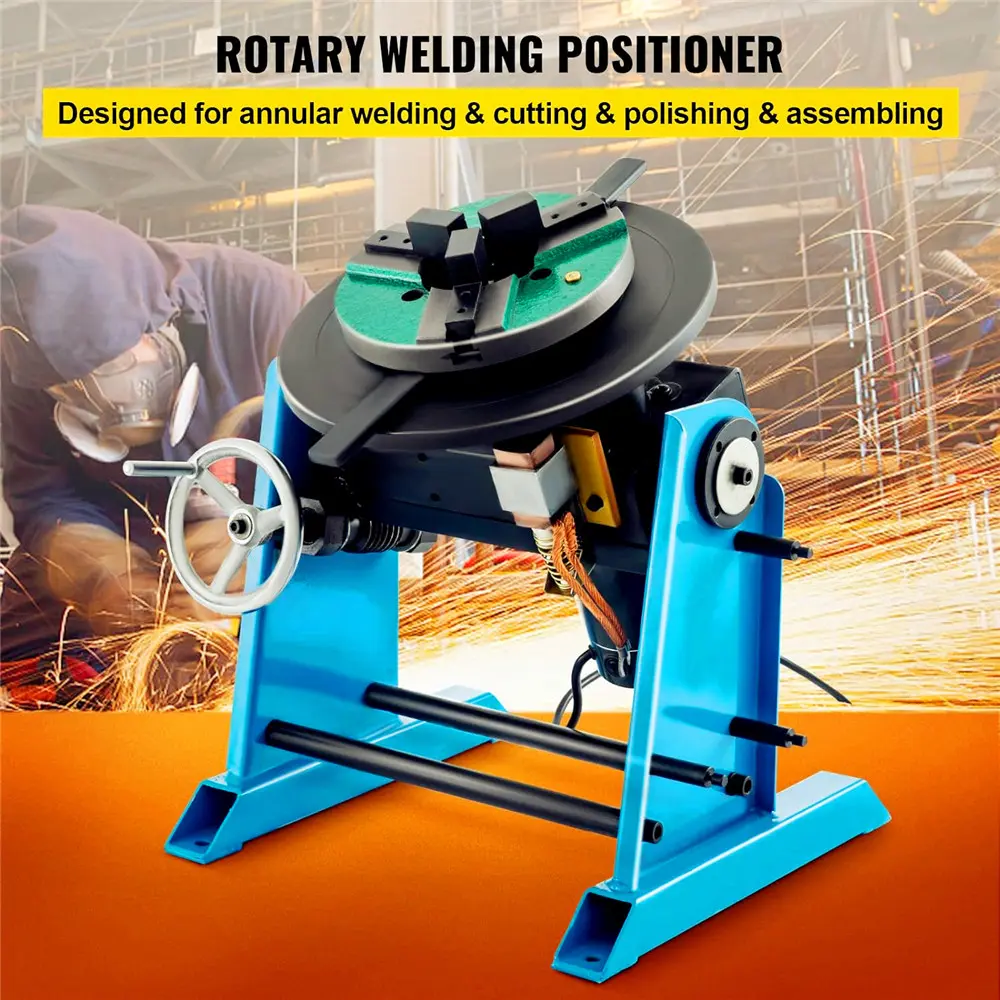

The term “POSITIONER” means the machines used to change position of work-piece on the table and to ensure smooth rotation of the work-piece at a required speed (variable speed in an extensive range). Positioner is ordinarily composed of (1) a table turning mechanism, and (2) table tilting mechanism.

products introduction

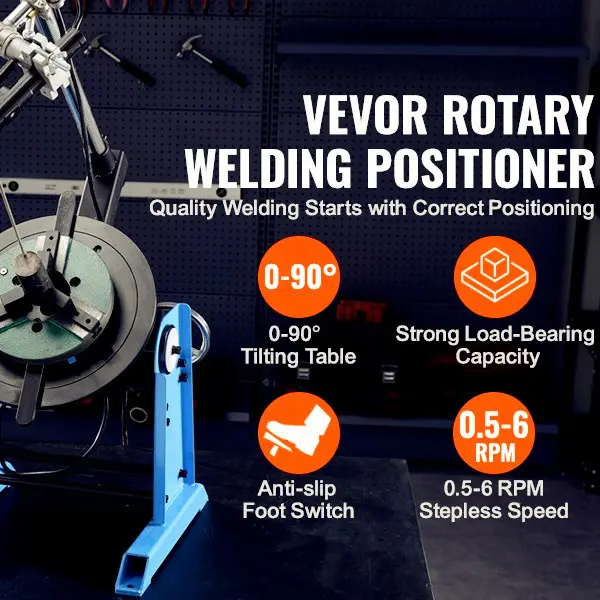

1,30KG Rotary Welding Positioner Turntable with 200mm Chuck & Foot Switch, 30KG 220V Rotary Welding Positioner Turntable Table 0-90o Welding Positioner Positioning Turntable 15RPM 310mm

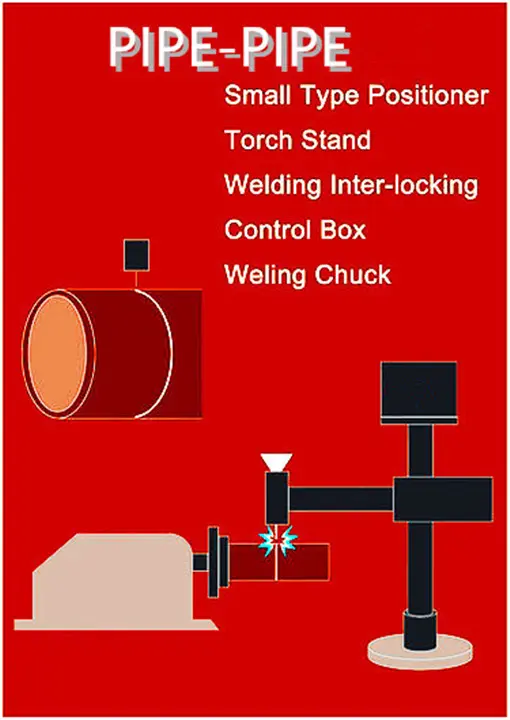

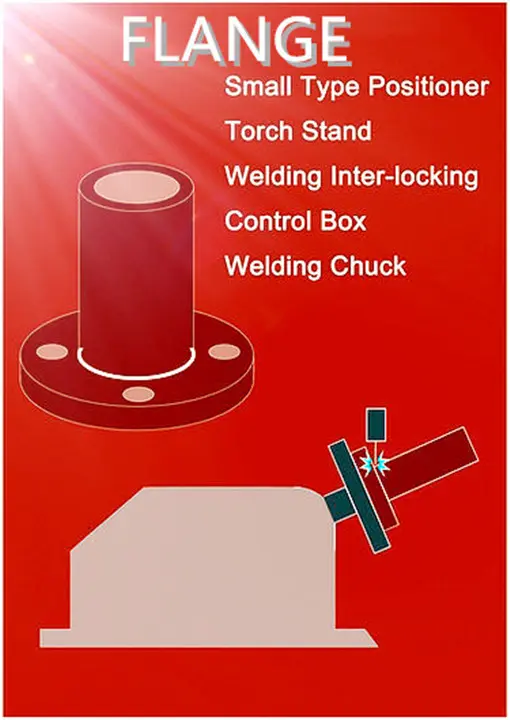

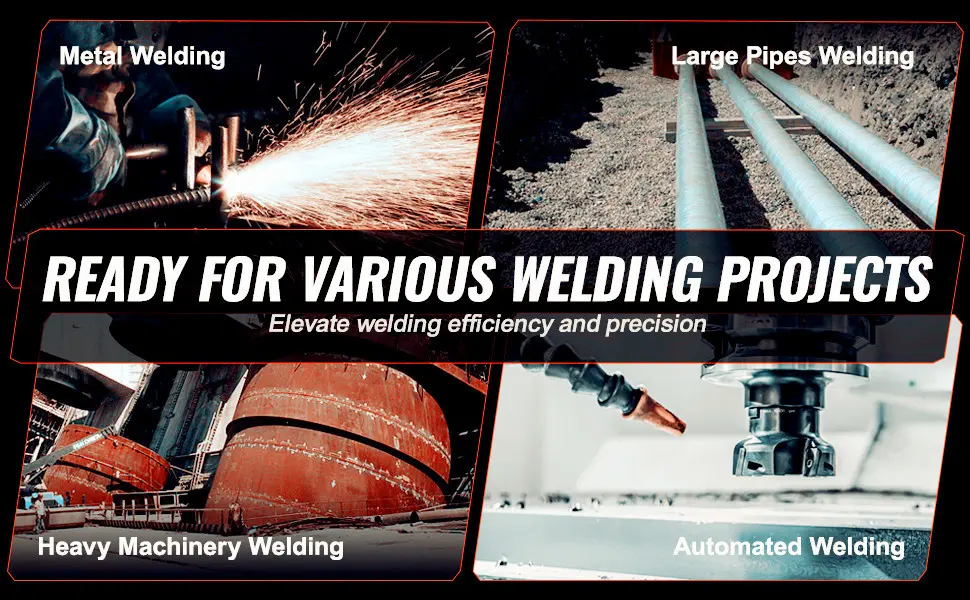

[Application] This welding positioner is designed for circle welding, annular welding, cutting, polishing, assembling etc. especially suitable for under 30KG flange, steel pipe and other seam welding.

[Easy to Control] Time and speed controllable, the time and speed is regulated by the knob on the machine(1-15r/min, driven by DC motor, stepless speed regulation can be achieved). Using foot pedal to control table rotation.

[Welding Gas] Support CO2 welding, MIG, MAG, TIG welding etc. Special design of anti-electromagnetic, which reduces the high frequency interference of TIG welding, and can improve the welding quality effectively.

[3 Jaw Lathe Chuck and Welding Table] Chuck diameter:200mm Table diameter: 315mm, Tilt angle: 0 degree - 100 degree The turning structure of worm and gear has the function of self-lock.

[Warranty] We provide 1 YEAR warranty for every our customer. If you have any questions, please feel free to contact us directly. We will give you a reply as soon as possible.

[Application] This welding positioner is designed for circle welding, annular welding, cutting, polishing, assembling etc. especially suitable for under 30KG flange, steel pipe and other seam welding.

▪ Smooth Rotation: This rotary welding positioner is driven by an 80W powerful motor, making it rotate smoothly and stably. Made of stainless steel and possessing good hardness and high strength. (horizontal/vertical loading capacity: 66lb/33lb). Get ready to easily rotate your project and get it set in the perfect position.

▪ 0-90º Tiltable Function: The worktable can be turned instantly between 0-90°. The turning structure of the worm and gear can be self-locked, ensuring it stays fixed at any angle you want. Chuck diameter: 12"/31 cm; Table Height: 15"/38 cm.

▪ High Quality Three-jaw Welding Chuck: The three jaws are reinforced, preventing the weldment pieces from moving and falling. With three jaws and a welding gun support, the table can clamp any workpiece for manual welding. High quality materials are used, so your projects can be completed at the highest standard.

▪ Stepless Speed Control: There is a foot switch provided for simple control of the table's 360 degrees rotation. Also, the speed can be regulated by the knob on the machine (stepless speed regulation: 1 - 15r/min).

▪ Extensive Applications: Especially suitable for flange, steel pipe, and other seam welding. It can be used for annular welding, cutting, polishing, and so on. Also perfect for grinding, testing, assembling and other processes. Use our position with confidence and get your projects requirements met at all times.

Features

▪ Owing to the proprietary collector of flat carbon earth type, the reduction gear is resistive to damage and is durable.

▪ Each type can be operated easily by a push-button or a foot switch for local operation.

▪ Because the structural design is standardized, the positioner is readily applicable to revolution and high-speed turning by a D.C. servo motor at option.

▪ Using a worm reduction gear, the revolution drive unit keeps smooth revolution of even an electric load, and safety is also ensured by a self-locking mechanism.

▪ Quick response to speed change operation by a dial.

▪ Non-paralleled rigidity and quality.

products detail

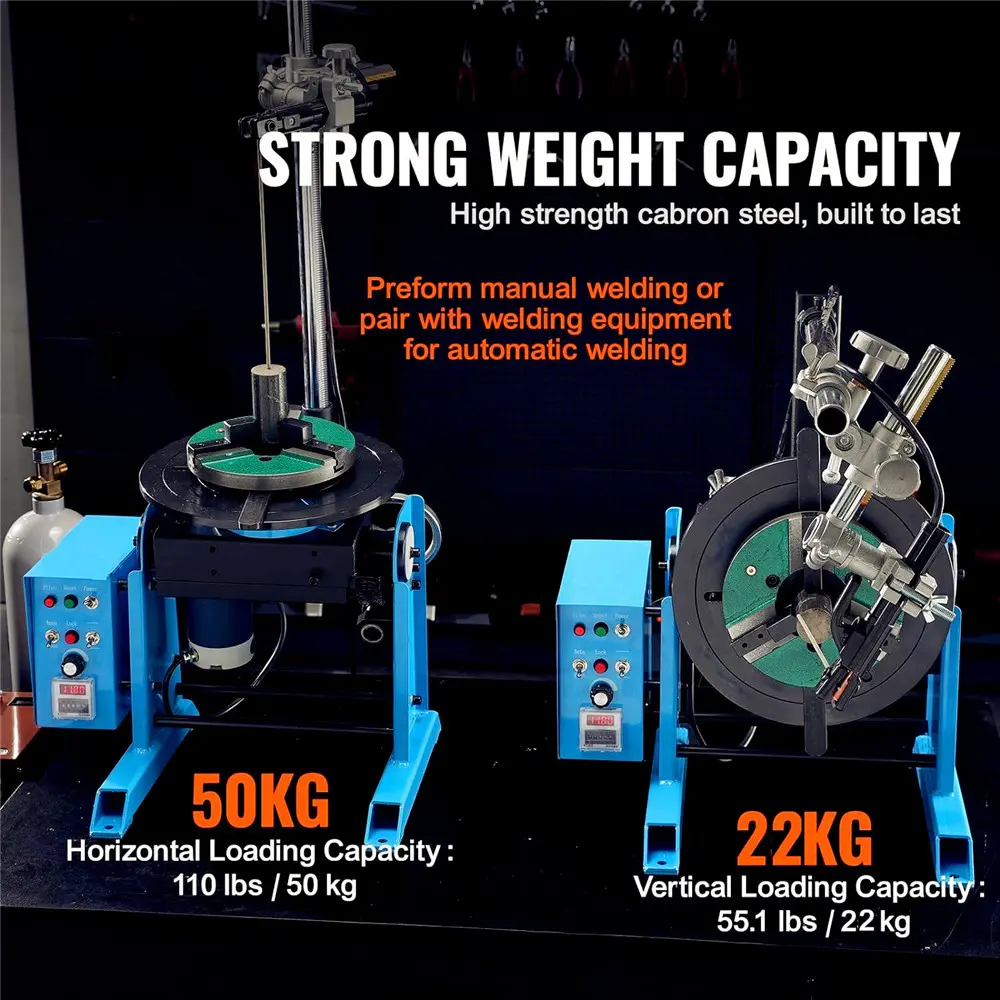

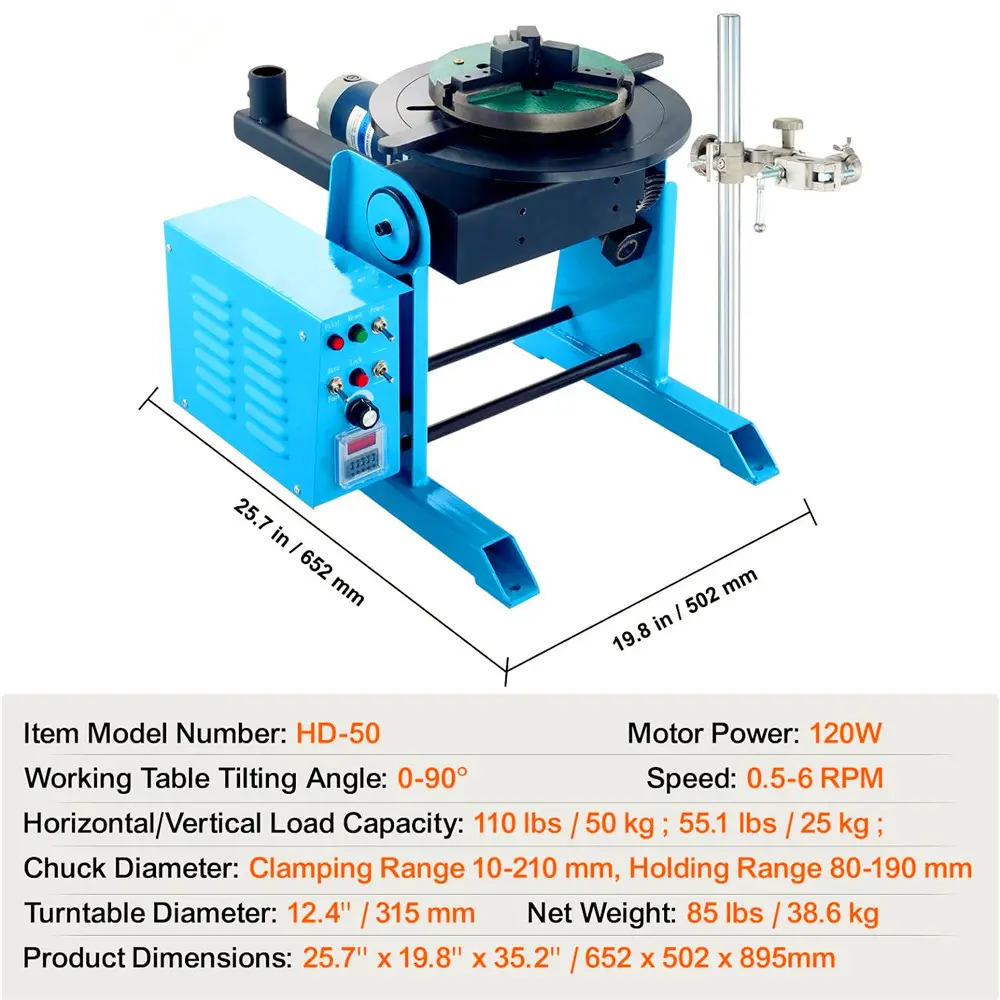

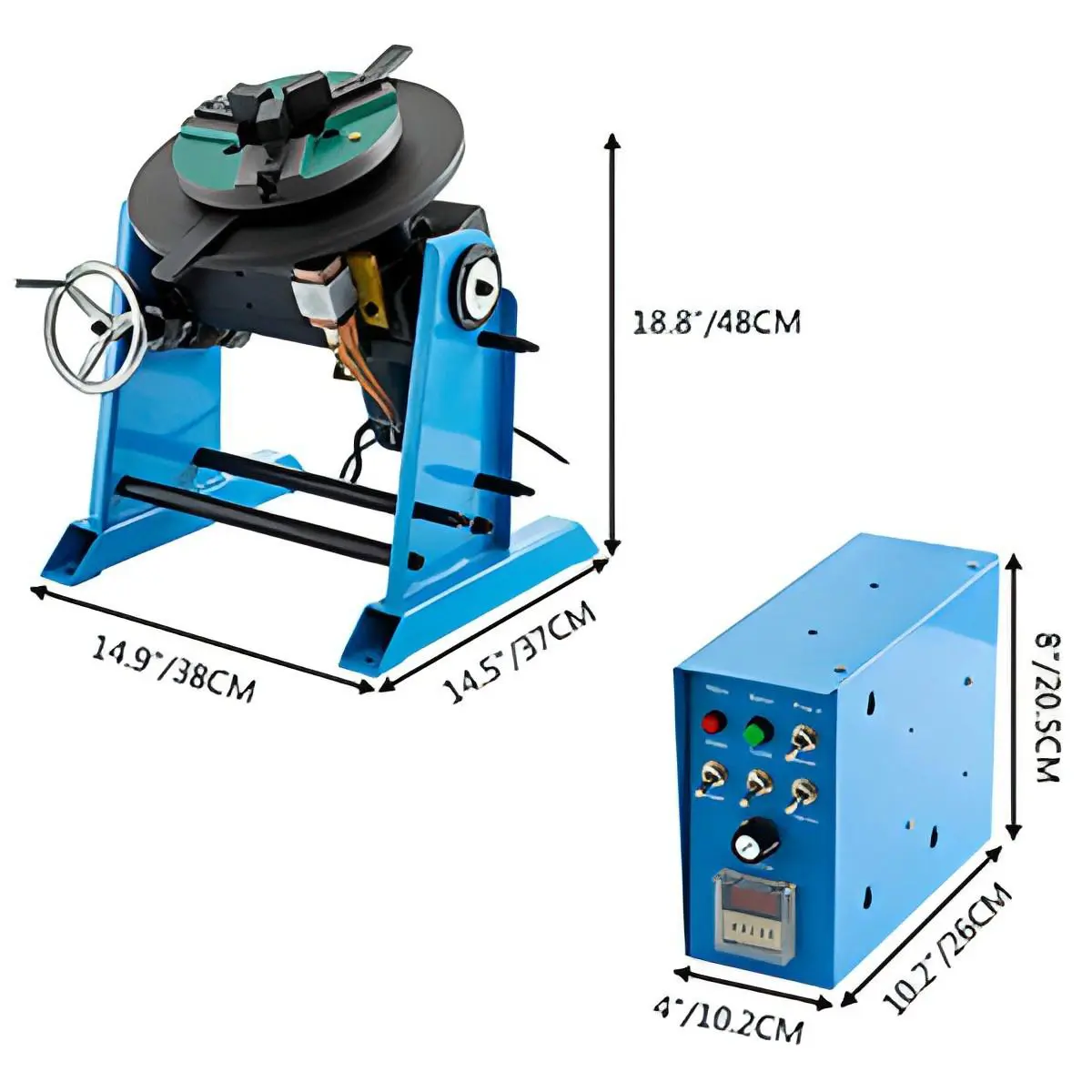

High Capacity

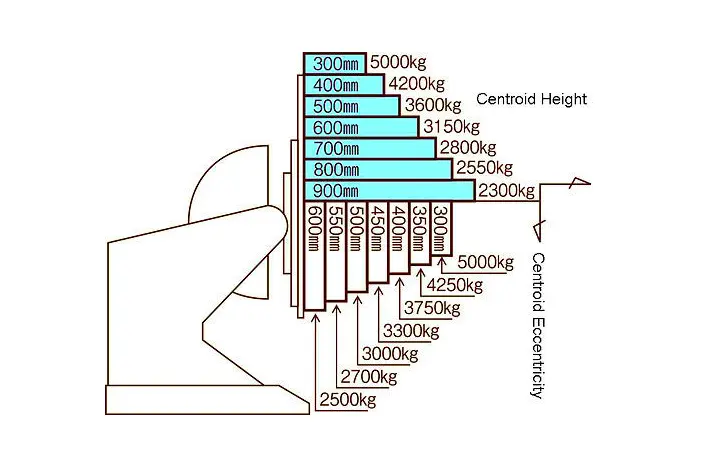

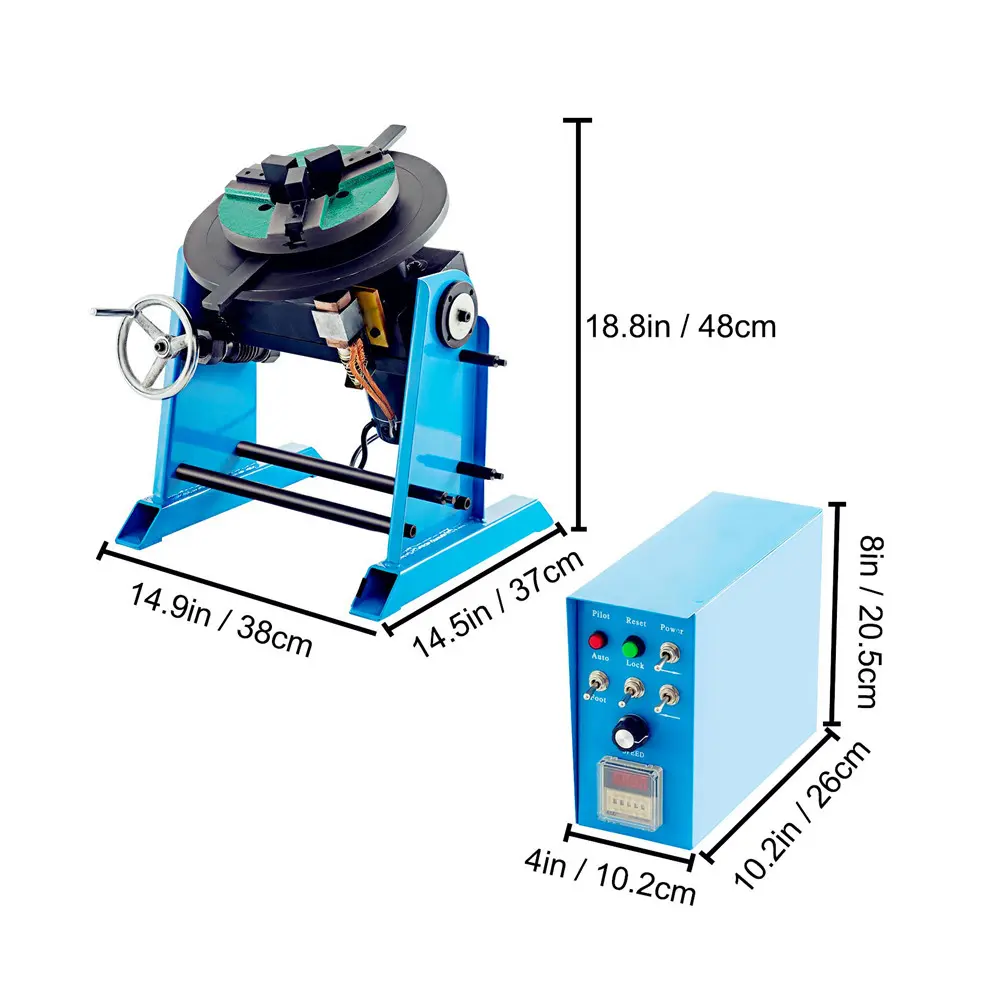

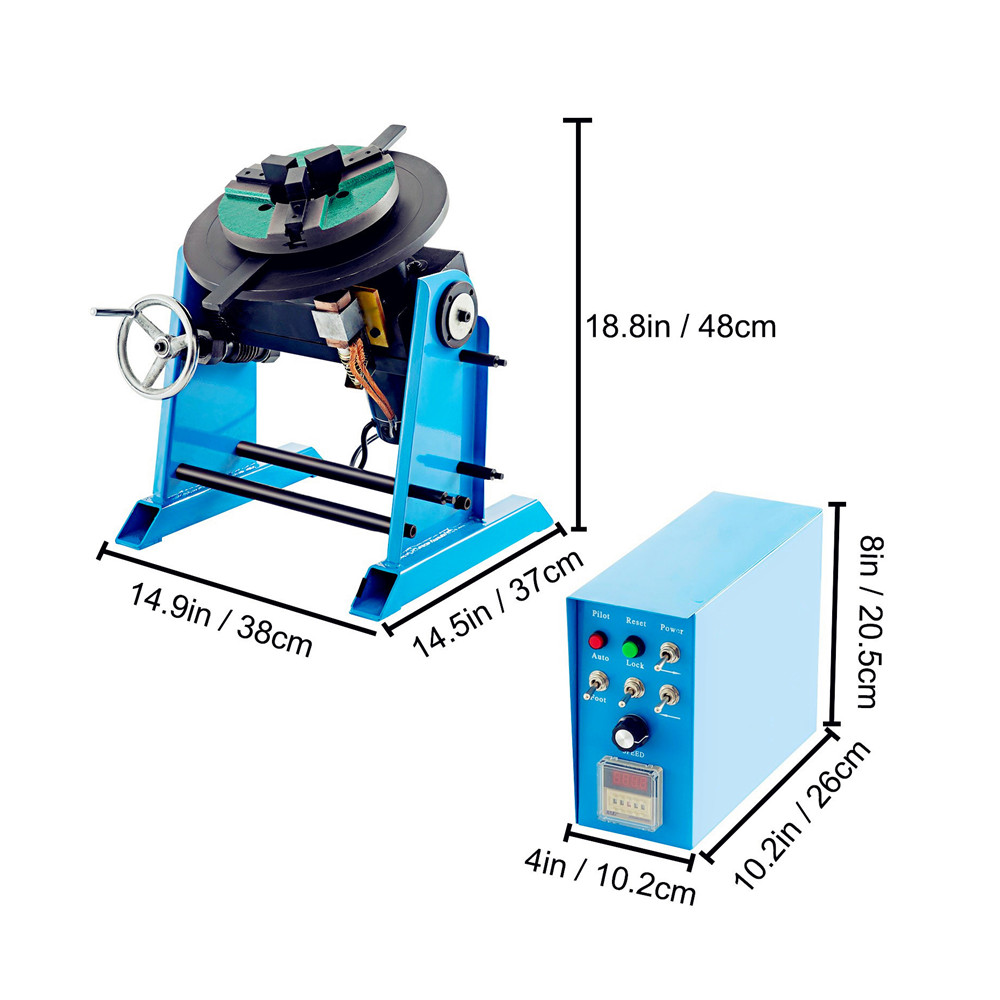

Horizontal loading capacity: 30 kg / 66 lbs; Vertical loading capacity: 15 kg / 33 lbs; Working table diameter: 310 mm / 12.2 inches; working table height: 380 mm / 15.0 inches. It is made of stainless steel, featuring high quality and durability.

0-90° Tiltable Table

The turning structure of welding table has the function of self-lock, and the worktable can be turned steplessly between 0-90°. It also can be fixed at any angle with tilt lock wrenches.

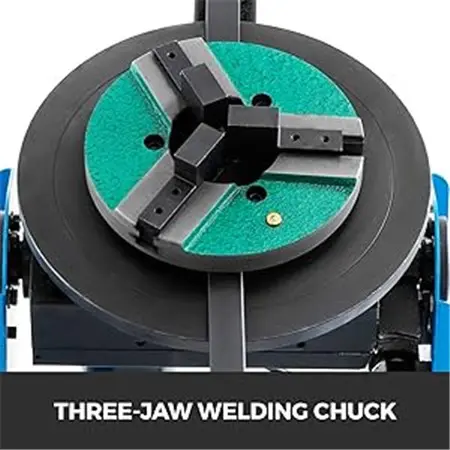

Three-Jaw Welding Chuck

The three claws are reinforced to prevent the weldments from moving and falling. It is also upgraded to be more accurate and more practical.

Anti-Slip Foot Switch

Through the foot switch, you are able to control table rotation, and the rotation speed is regulated by the knob on the machine(1-15r/min stepless speed regulation).

Time-Controller Box

Time-controller can be furnished to control the working condition and working time. Setting time period to make the welding positioner working safely, saving energy as well.

Adjustable Welding Gun Support

The adjustable-welding gun support can be furnished to fix the position of the welding torch for accurate adjustment and improved welding process.

Heavy-duty Rotary Welding Positioner

The positioner is suitable for max. 30 kg flange, steel pipe, and seam welding, supporting CO2 welding, MIG, MAG, TIG welding, etc. Driven by an 80W high-quality DC motor, it rotates smoothly & stably. The device can be fixed on the workbench, or a special tool for clamping the workpiece by manual welding, or can be used in conjunction with a welding manipulator to realize automatic welding.

Horizontal Loading Capacity: 30 kg / 66 lbs

Vertically Loading Capacity: 15 kg / 33 lbs

0-90° Tiltable Table

Three-Jaw Welding Chuck

Time-Controller Box

specification

| Voltage | 110V |

| Horizontal Loading Capacity | 30 kg / 66 lbs |

| Vertical Loading Capacity | 15 kg / 33 lbs |

| Working Table Diameter | 310 mm / 12.2 inches |

| Central Hole Diameter | 25 mm / 1.0 inch |

| Rotary Motor | 80W |

| Working Table Tilting Angle | 0-90° |

| Working Table Speed | 1-15r/min |

| Suitable Clamp | KP-125\200\300 |

Package Content

1 x Main Body

1 x Controller

1 x 200 mm Chuck

1 x Welding Torch Bracket