POPWELD Automated Welding Positioners

products description

Everything You Need to Know About Welding Positioners: A Comprehensive Guide

What if there was a tool that could significantly optimize your welding operations, while also reducing labor costs and increasing output?

Enter welding positioners, the versatile and powerful tools that ensure a more consistent rate of production. If you are considering automating your welding operations, have already automated your welding operations, and want to optimize them, you have come to the right place.

In this guide, we will talk you through the basics of welding positioners and explain how to choose the right one for your needs.

The Importance of Welding Positioners in Robotic Welding

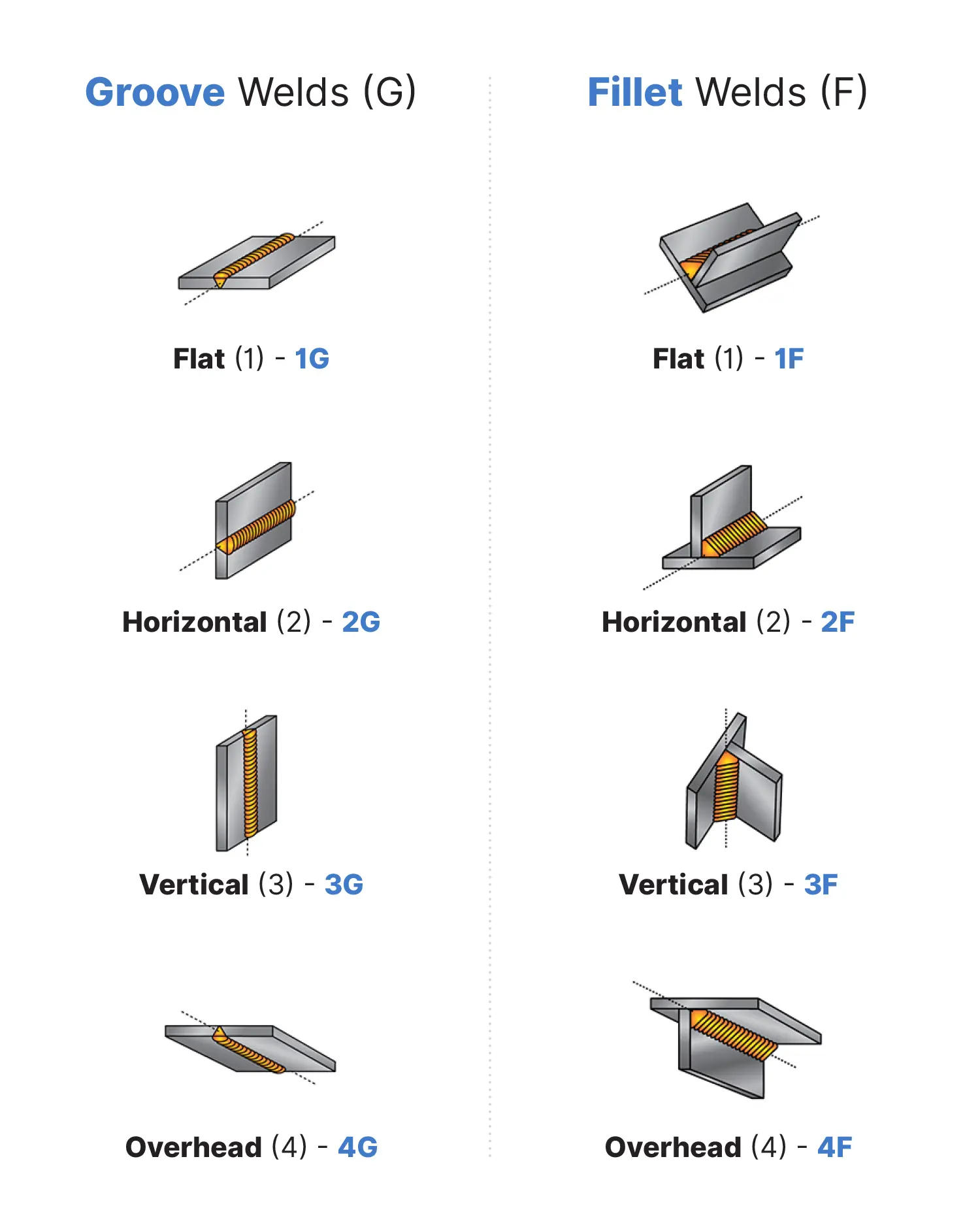

As you may know, fabricators need to respect welding procedure requirements on technical drawings. This can specify welding positions like flat, horizontal, vertical, and overhead. These positions need to be respected in order to have the required structural strength for the assembly. Welding positioners play a crucial role in meeting these requirements.

First, here is a recap of those welding positions:

| Welding Position | Description |

| Flat Position (1st) | The flat position is the most common and straightforward weld orientation. It involves welding on the upper side of a horizontal plane. |

| Horizontal Position (2nd) | In the horizontal position, the axis of the weld lies in a horizontal plane while the weld itself is applied on a vertical plane. |

| Vertical Position (3rd) | The vertical position involves welding with the axis of the weld being vertical. Gravity poses a challenge in this position as it affects the weld pool. |

| Overhead Position (4th) | The overhead position requires welding from the underside of the joint. It is often considered the most difficult position due to the force of gravity. |

| Type of Weld Joint | Description |

| Fillet Weld (F) | Fillet welds join two surfaces that are perpendicular or at an angle. |

| Groove Weld (G) | Groove welds are made in the groove between two pieces or their edges. |

Benefits of Using Welding Positioners

Welding positioners offer many benefits that can transform your welding operations, making them more efficient, precise, and safe.

Increased Efficiency:

Welding positioners automate the task of positioning the workpiece, saving time and reducing labor costs. They allow for continuous welding, eliminating the need to stop and manually adjust the position of the workpiece. This results in faster completion of jobs and increased productivity.

Maximize arc-on time of welding robot:

Welding positioners provide a stable platform, enabling the welding robot to continuously weld without having to wait for an operator to adjust the workpiece setup. This increases the arc-on time of the robot, reduces idle times, and increases productivity.

Improved Weld Quality:

Welding positioners enable precise positioning of the workpiece, ensuring optimal weld quality. They allow for consistent speed and angle of welding, which reduces the likelihood of weld defects and rework.

Enhanced Safety:

By securely holding and manipulating the workpiece, welding positioners reduce the risk of workplace accidents. They eliminate the need for workers to manually handle heavy or awkwardly shaped workpieces, reducing the risk of injuries.

Greater Versatility:

With a variety of welding positioners available, you’ll be equipped to handle a wide range of workpieces and welding operations. Whether you’re working with cylindrical parts or large, heavy components, there’s a welding positioner to suit your needs.

Consistency:

Welding positioners enable consistent welding results, which is crucial for industries where the quality and integrity of welds are paramount. By ensuring a consistent welding speed and angle, they contribute to uniform weld beads and high-quality final products.

Mark Barglof, President of Kinetic Technologies LLC, highlights the importance of positioners in robotic welding systems.

products detail

“The addition of a flexible positioning system not only justifies the investment in automation but also multiplies the ROI. These positioners, equipped with fixture plates and mounting locations, extend beyond single-part use, driving substantial efficiency and financial gains in the long run. They have proven crucial in making the leap to automation more feasible and profitable for many businesses, time and again.”

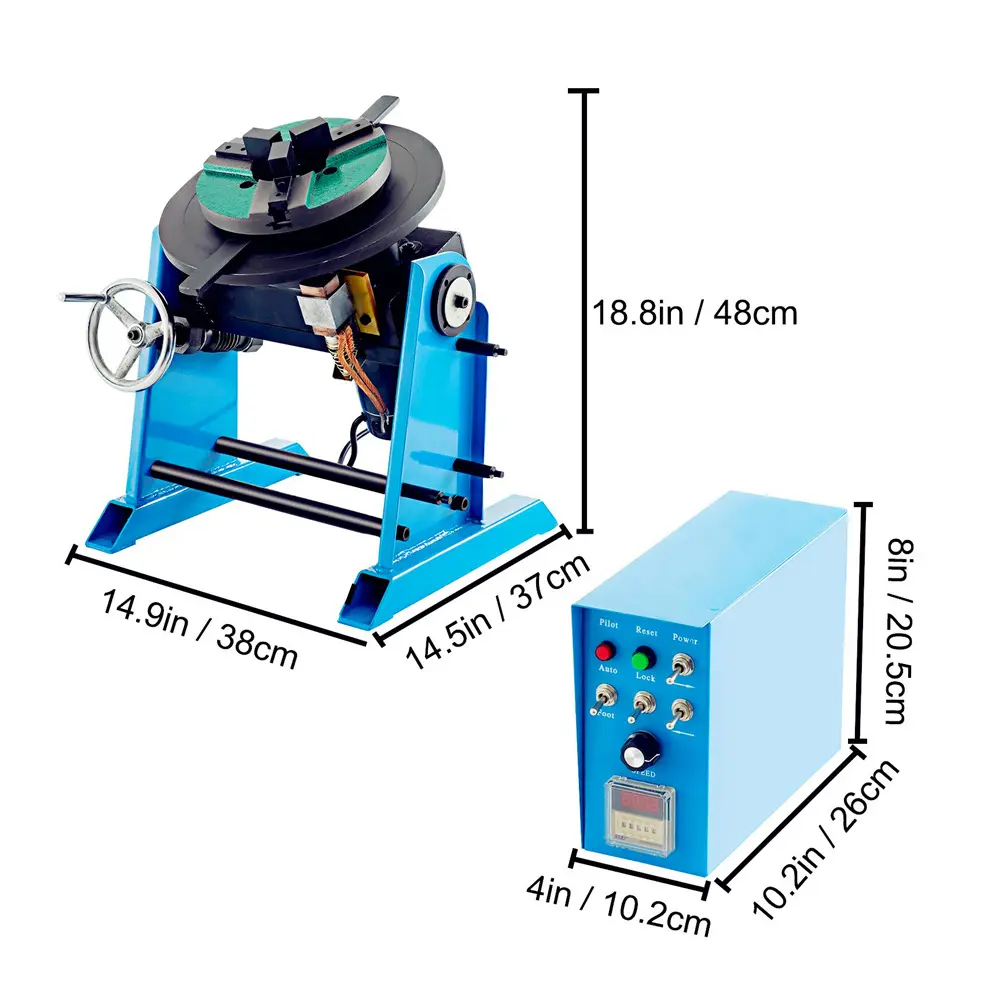

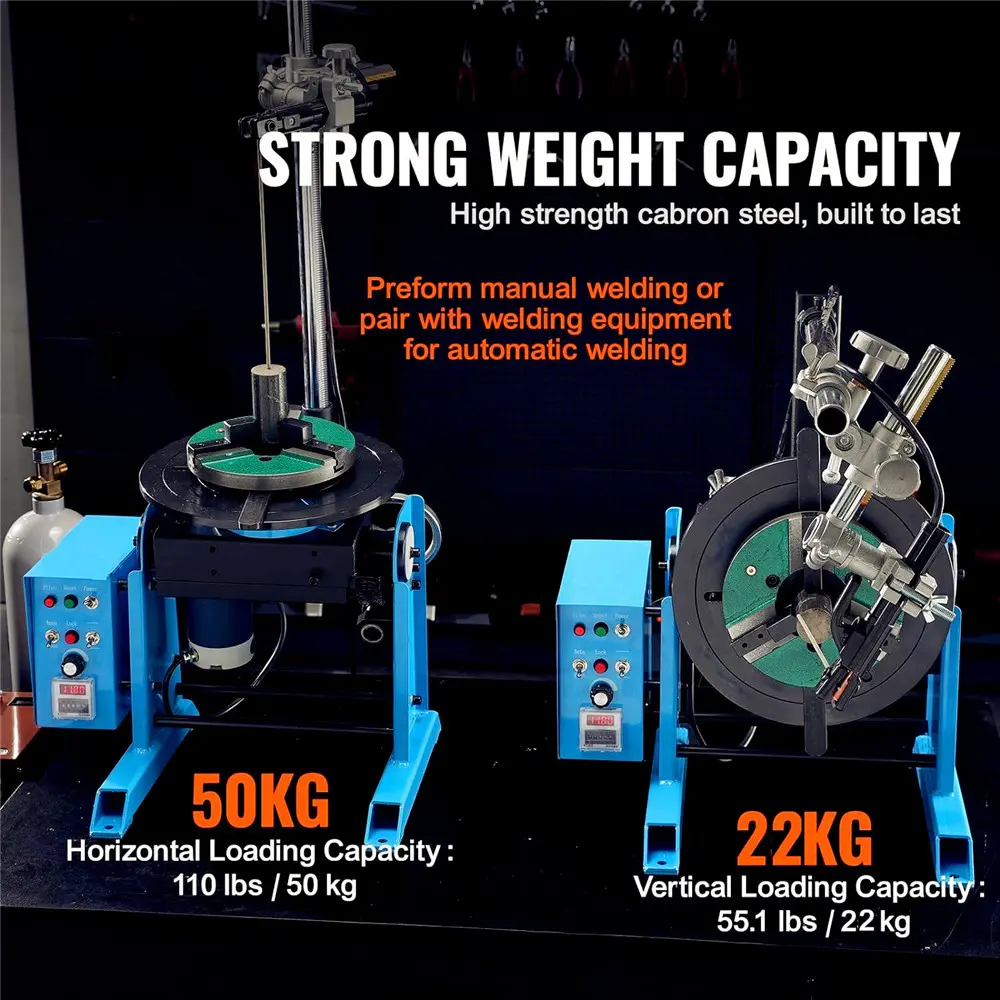

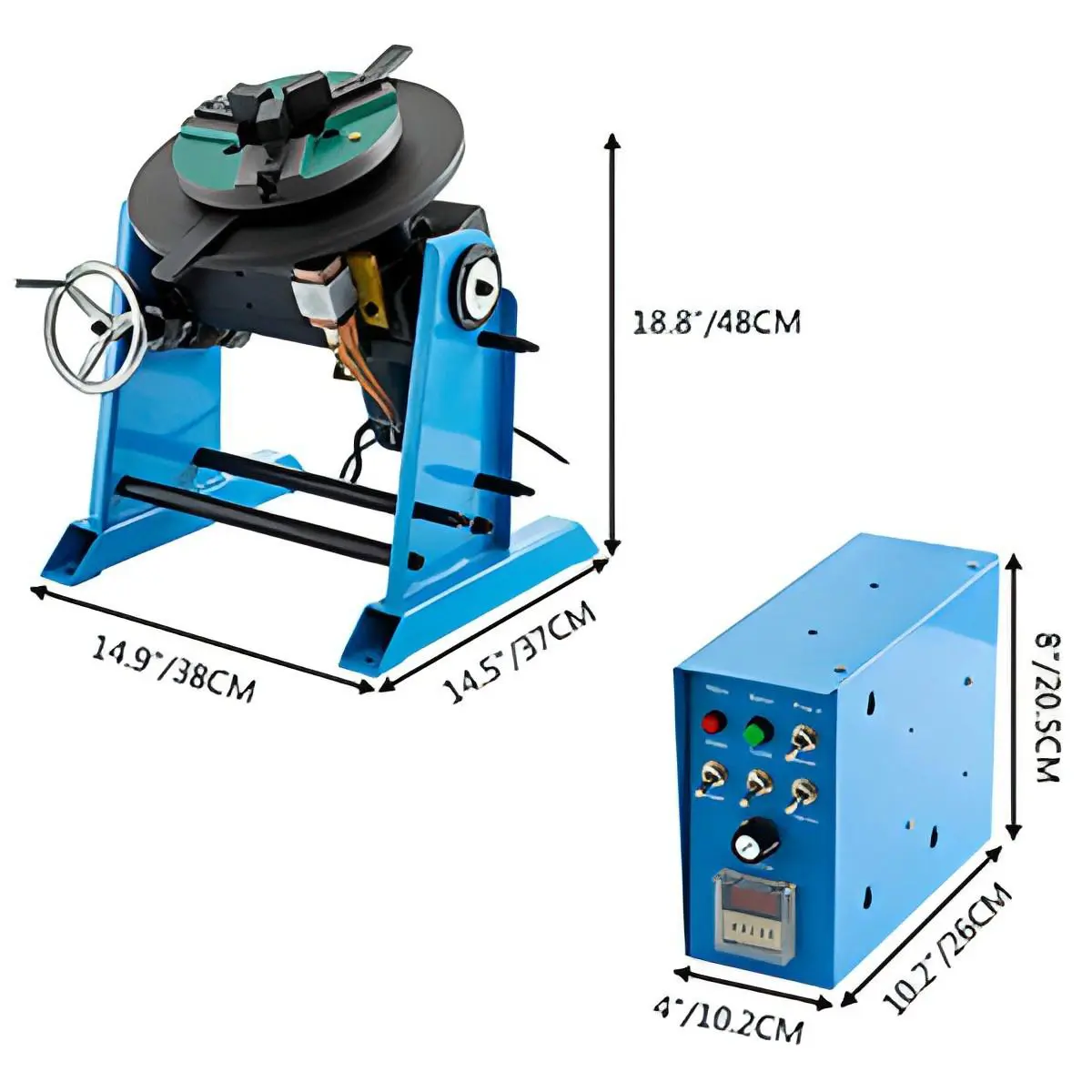

High Capacity

Horizontal loading capacity: 30 kg / 66 lbs; Vertical loading capacity: 15 kg / 33 lbs; Working table diameter: 310 mm / 12.2 inches; working table height: 380 mm / 15.0 inches. It is made of stainless steel, featuring high quality and durability.

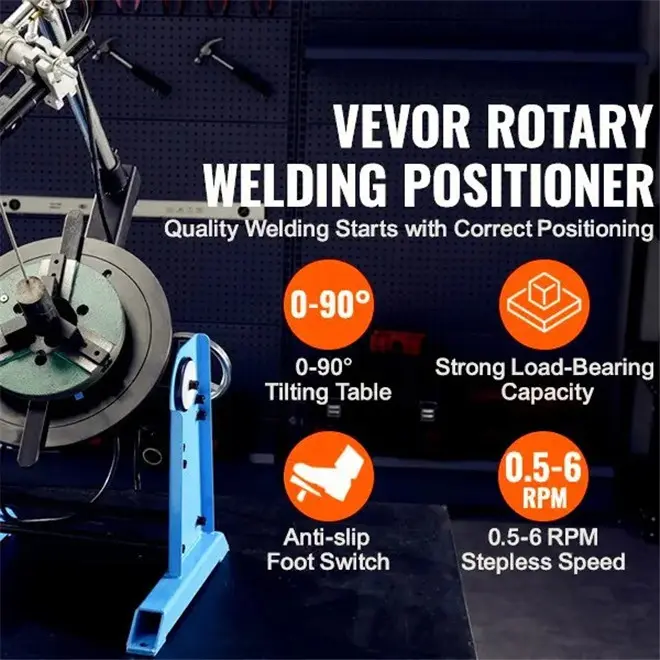

0-90° Tiltable Table

The turning structure of welding table has the function of self-lock, and the worktable can be turned steplessly between 0-90°. It also can be fixed at any angle with tilt lock wrenches.

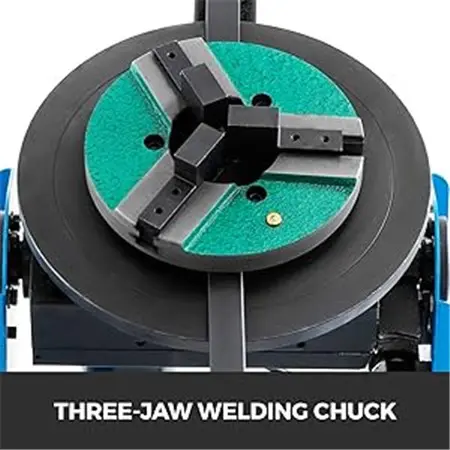

Three-Jaw Welding Chuck

The three claws are reinforced to prevent the weldments from moving and falling. It is also upgraded to be more accurate and more practical.

Anti-Slip Foot Switch

Through the foot switch, you are able to control table rotation, and the rotation speed is regulated by the knob on the machine(1-15r/min stepless speed regulation).

Time-Controller Box

Time-controller can be furnished to control the working condition and working time. Setting time period to make the welding positioner working safely, saving energy as well.

Adjustable Welding Gun Support

The adjustable-welding gun support can be furnished to fix the position of the welding torch for accurate adjustment and improved welding process.

Heavy-duty Rotary Welding Positioner

The positioner is suitable for max. 30 kg flange, steel pipe, and seam welding, supporting CO2 welding, MIG, MAG, TIG welding, etc. Driven by an 80W high-quality DC motor, it rotates smoothly & stably. The device can be fixed on the workbench, or a special tool for clamping the workpiece by manual welding, or can be used in conjunction with a welding manipulator to realize automatic welding.

Horizontal Loading Capacity: 30 kg / 66 lbs

Vertically Loading Capacity: 15 kg / 33 lbs

0-90° Tiltable Table

Three-Jaw Welding Chuck

Time-Controller Box

specification

| Voltage | 110V |

| Horizontal Loading Capacity | 30 kg / 66 lbs |

| Vertical Loading Capacity | 15 kg / 33 lbs |

| Working Table Diameter | 310 mm / 12.2 inches |

| Central Hole Diameter | 25 mm / 1.0 inch |

| Rotary Motor | 80W |

| Working Table Tilting Angle | 0-90° |

| Working Table Speed | 1-15r/min |

| Suitable Clamp | KP-125\200\300 |

Package Content

1 x Main Body

1 x Controller

1 x 200 mm Chuck

1 x Welding Torch Bracket