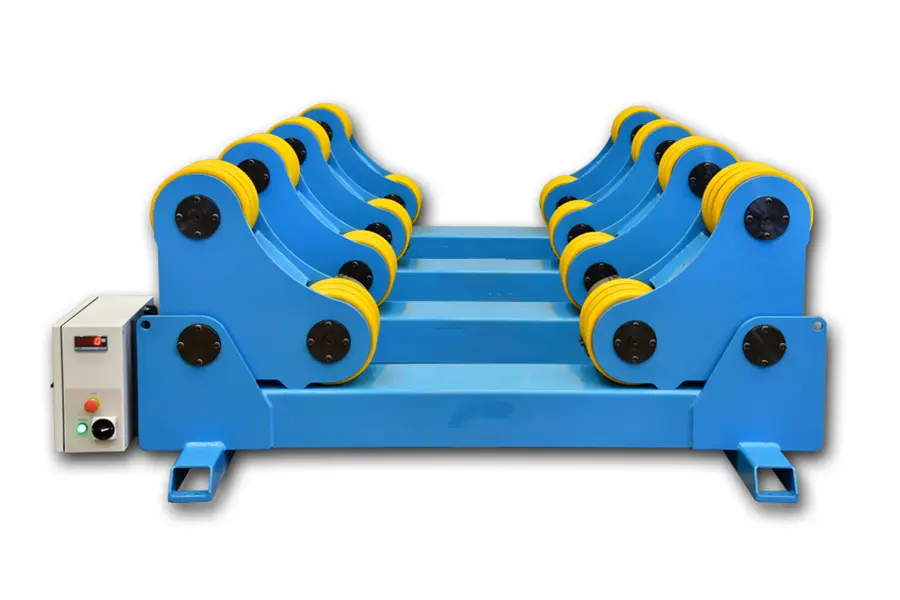

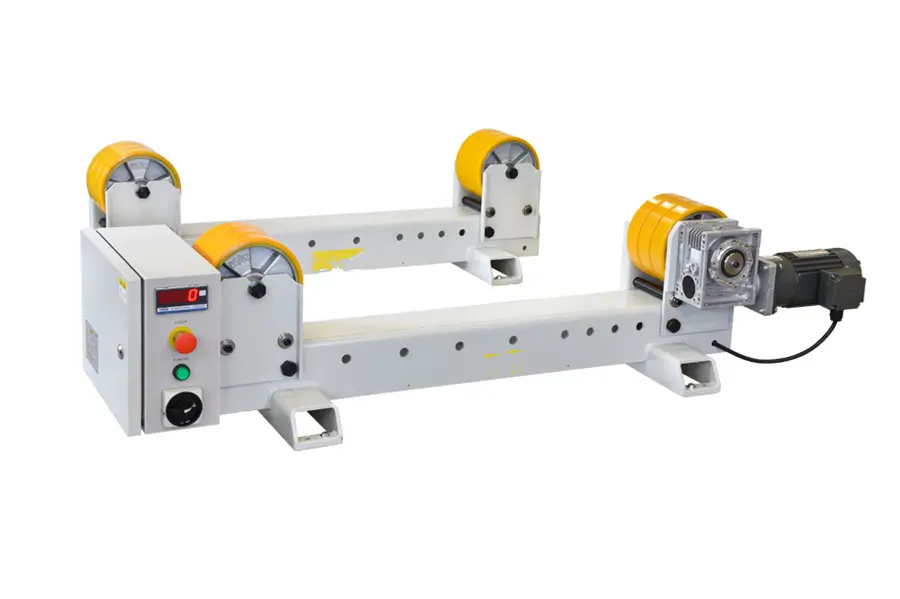

POPWELD Automated Welding Roller Frame

Popweld roller frame / turning rollers

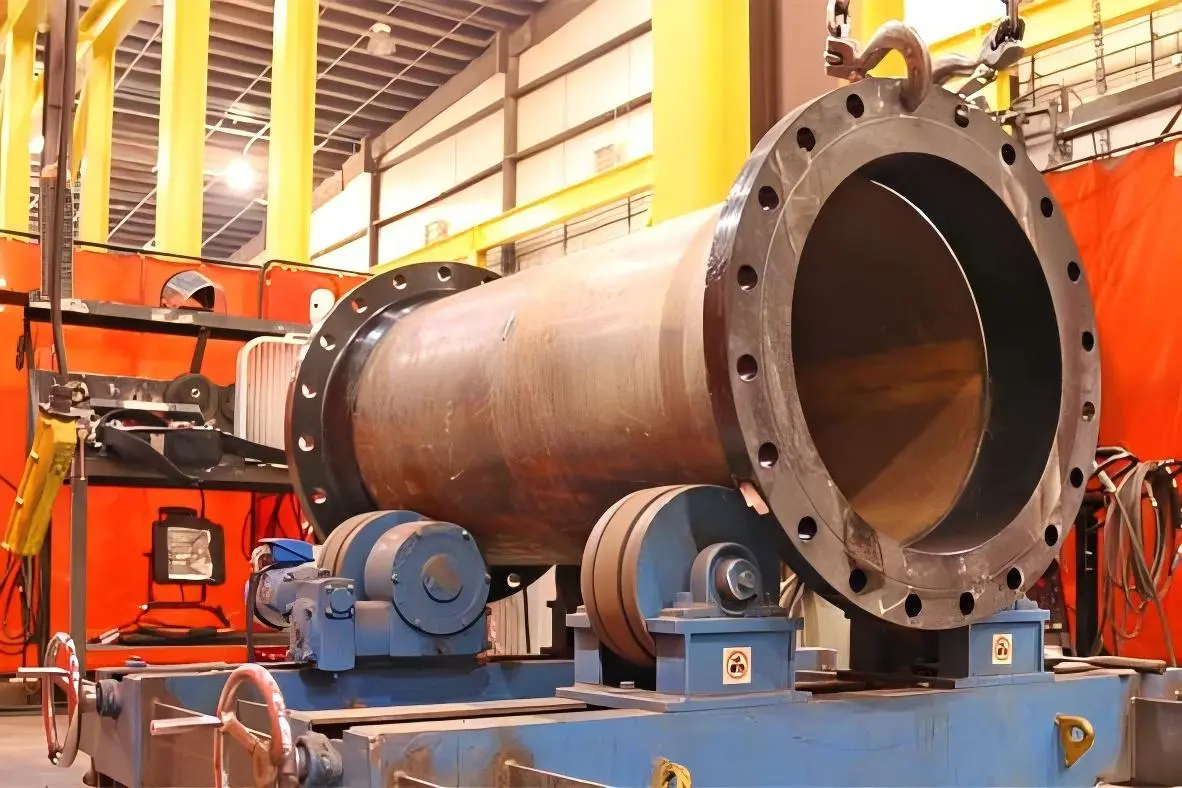

WELDING TURNING ROLLS FOR VESSEL, TANK AND PIPE

POPWELD’s turning rolls are a great way to transform your welding output while increasing efficiency, quality of workmanship as well as minimizing handling and crane use.

products description

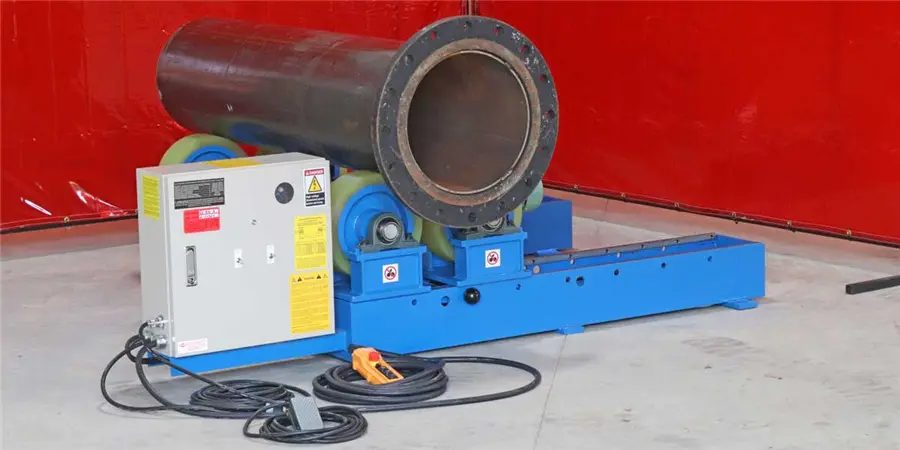

Automate Your Processes: Fully automated pipe handling & alignment systems fully engineered by our team of professionals

Automate Your Processes: Fully automated pipe handling & alignment systems fully engineered by our team of professionals Improved Welding Output: Full control over handling of pipes and safer, faster and reduced dependence on cranes

Improved Welding Output: Full control over handling of pipes and safer, faster and reduced dependence on cranes Reduced Cycle Times: Up to a 65% decrease in fit up cycle times with precise handling and alignment

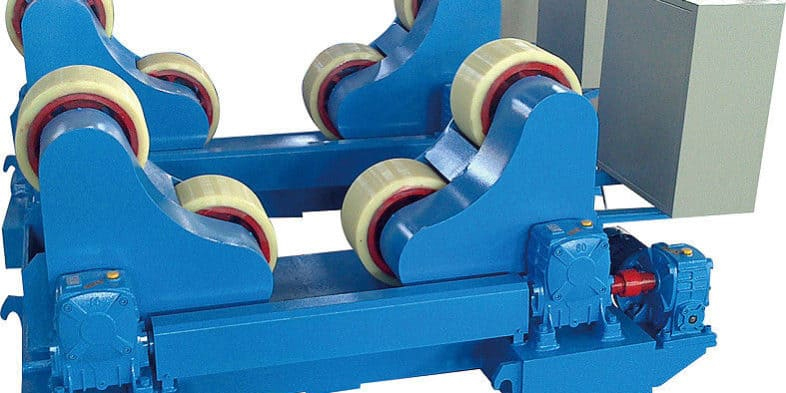

Reduced Cycle Times: Up to a 65% decrease in fit up cycle times with precise handling and alignment Height Adjustability: Height adjustable vessel rolls for any capacity that are easy to level with workpieces

Height Adjustability: Height adjustable vessel rolls for any capacity that are easy to level with workpieces Controls: Easy to use touch screen and hand pendant controls

Controls: Easy to use touch screen and hand pendant controls

Key Benefits

Dramatically cuts fit-up times, improving efficiency and reducing project timelines compared to traditional methods.

Capable of managing vessels and cylindrical objects weighing up to 60 tons, making it ideal for large-scale fabrication.

Accommodates workpieces with diameters ranging from 24" to 216", offering flexibility for a wide range of cylindrical components.

Reduces reliance on cranes, making the process safer and more streamlined, especially in heavy fabrication environments.

Improves safety conditions for workers while ensuring precise alignment and full control over the fit-up and welding process.

The growing line system minimizes manual effort, reducing worker fatigue and optimizing overall productivity.

products features

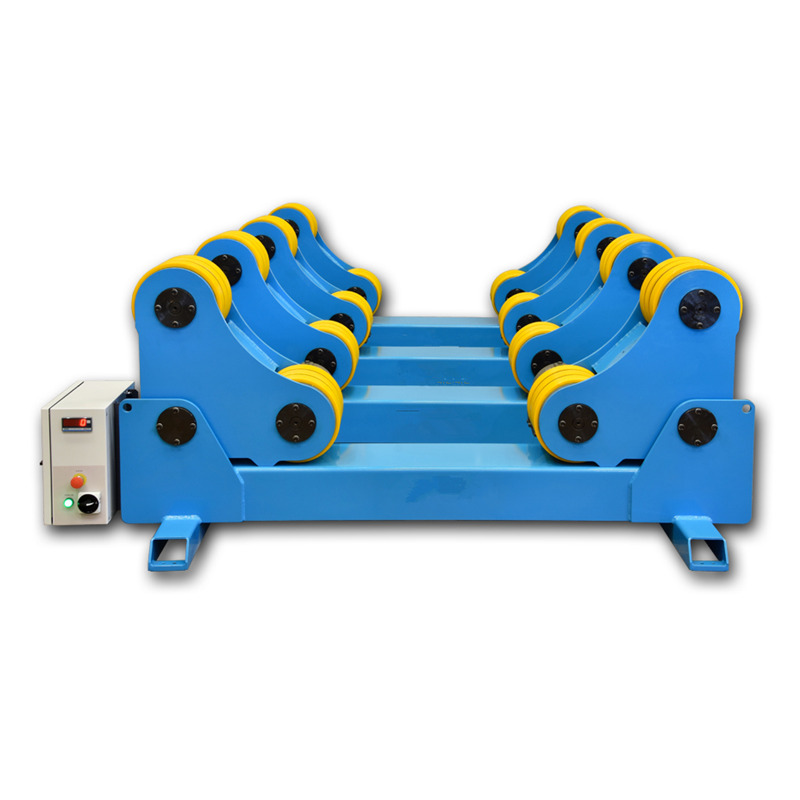

You can enjoy the following features that our turning rolls have:

Strong and durable turning roll base and frame

All parts of the machine are sandblasted before painted

Control panel is secured in a brace inside a gear box

All electronic parts and components come with CE certificates

With other manufacturers, you’ll get less and less real features about the machines. But with POPWELD’s turning rollers, we are transparent in explaining our equipment to you.

You can apply and use POPWELD’s turning rollers for whatever round workpiece it may be. The most common uses for it include:

Shipyard and shipbuilding parts and components

Pressure and water vessels

Boilers

Piping and tubing

Water storage vessels

And many more!