Welding Systems and Heavy-Duty Equipment Can Help You Today

The Customer's New Process

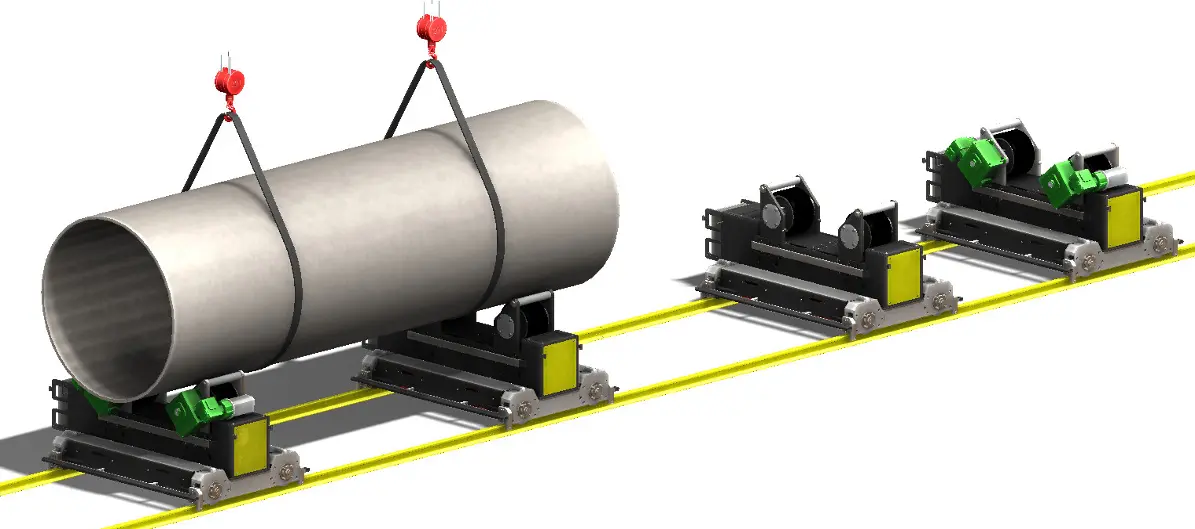

- A pipe is loaded onto each pair of idler/driver – driver/idler

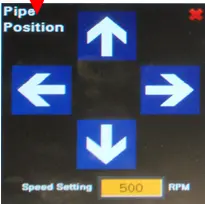

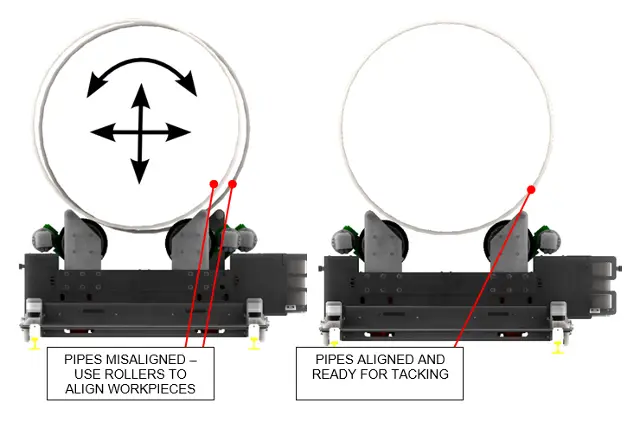

- Once pipes are in place, the fit-up is completed by one operator using a combination of a touchscreen HMI and joystick. move pipe up/down/in/out/left/right/slight tilt/rotate. Pipe is manipulated into a perfect fit-up position.

-

- Welder tack welds, then completes a root pass.

Weld manipulator further

- Completed double joints are then sent for further processing

The Bottom Line

Cycle Time: 2 ¾ Hour (65% reduction from old process)

Labor: 1 welder, 1 assistant (83% reduction in labor)

Available productivity options:

- Weld Cameras

- Data Acquisition

- iPad Controls

HSE Results:

- Reduced risk of dropped loads, as no overhead cranes are used.

- No manual uncontrolled pipe manipulation – no sledgehammers.

- Removal of unsafe wood cribbing with the introduction of automated pipe manipulation

- Worker can safely operate entire system from a safe distance