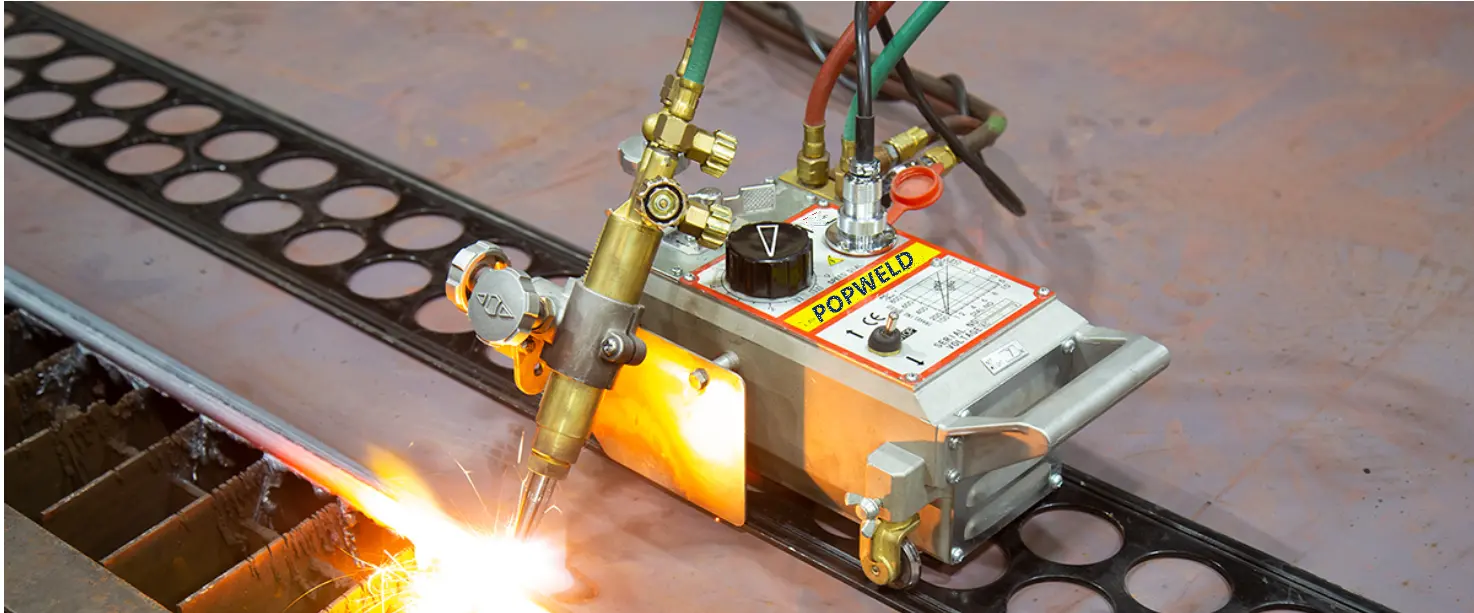

POPWELD Automated Cutting Machine

Standard Equipment

The Ultimate Portable Cutting Solution.

Versatile Cutting Methods

The POPWELD cutting machine achieves precise straight, circle, and bevel cuts, harnessing the capabilities of a single torch combined with a selection of three distinct, premium POPWELD Series 100 torch tips.

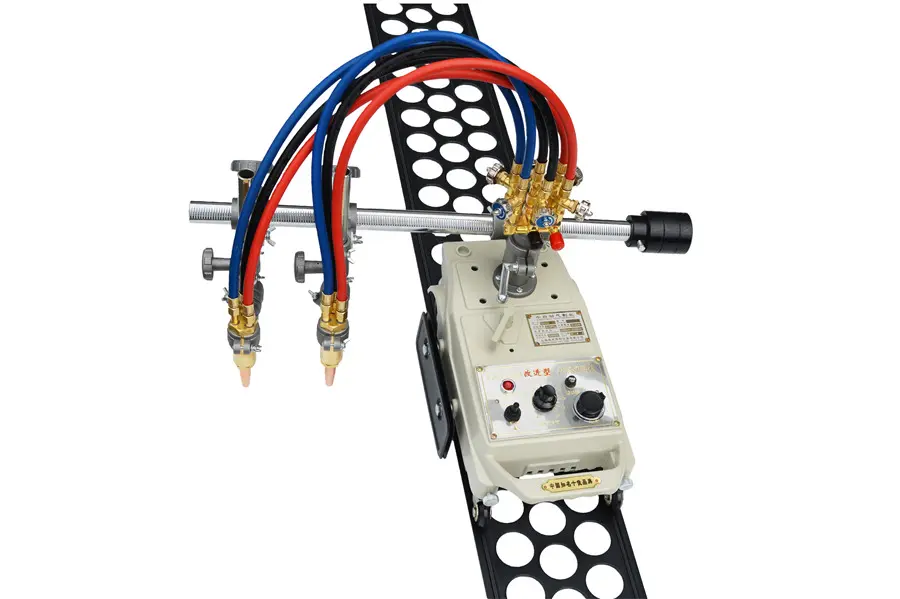

*Bevel cutting shown in photo.

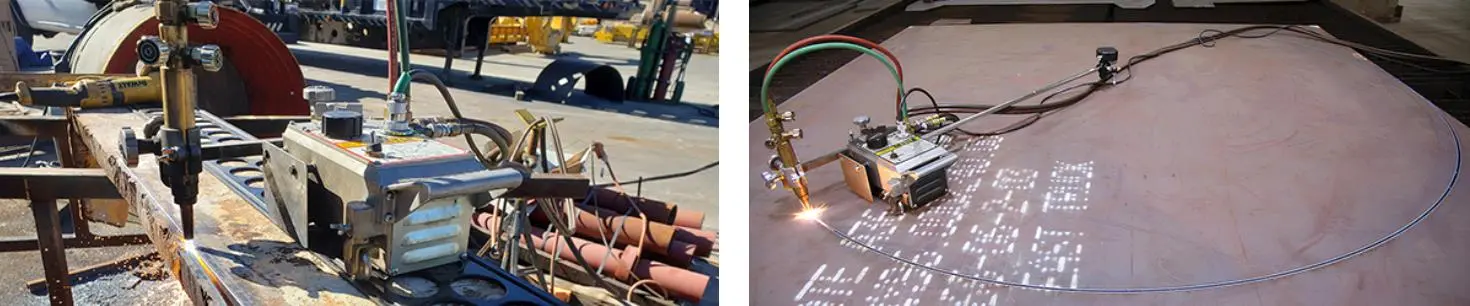

Straight Cut

Circle Cut

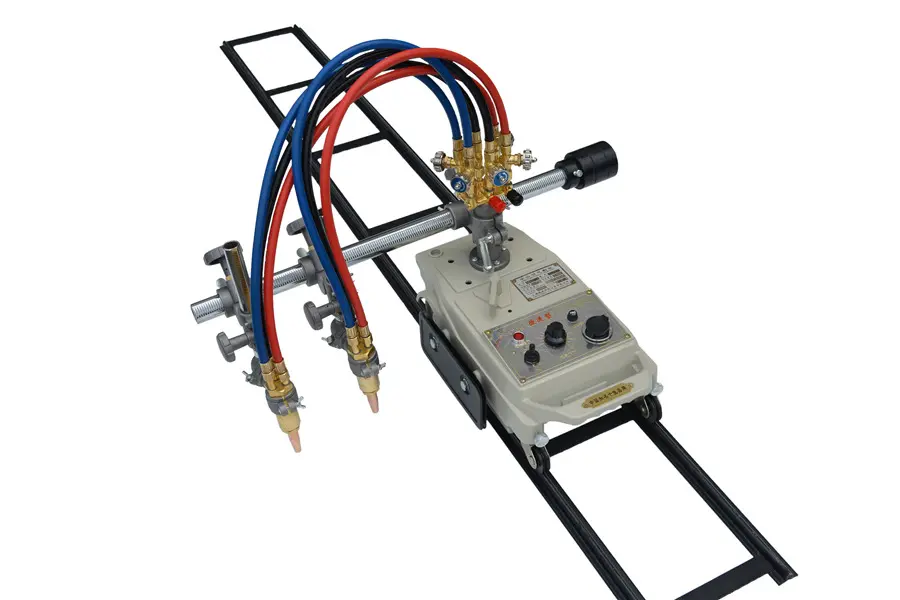

Seamless Changeover From Existing Equipment.

Compatible With The Radiagraph Track System

Operators of the discontinued Radiograph will find the cutting machine can serve as a seamless replacement, utilizing the same robust track system.

Additional extendable 72in (1800mm) track sections can be purchased to facilitate the cutting of elongated parts.

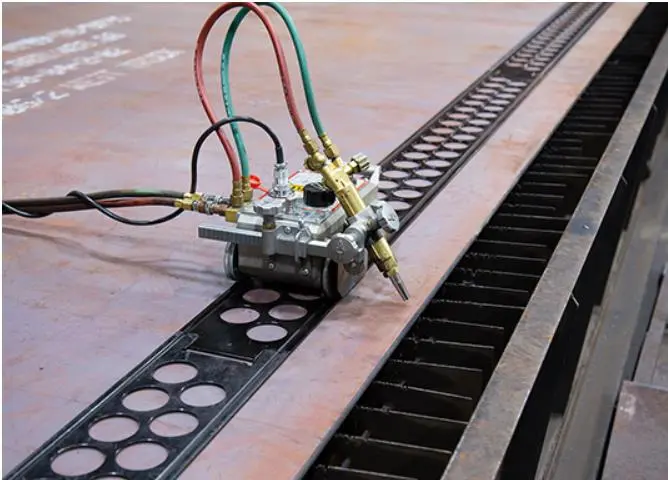

Consistent Cuts, Every Time.

Stepless Drive System

Guarantees a reliable travel speed, maintaining consistency even under high-temperature conditions while delivering unwavering and uninterrupted cutting performance.

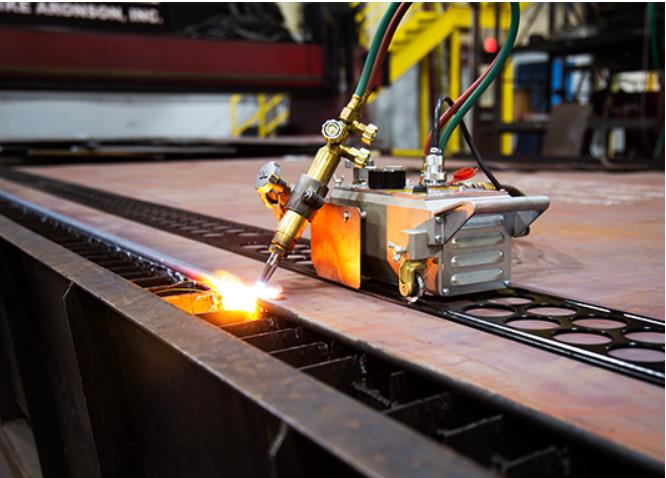

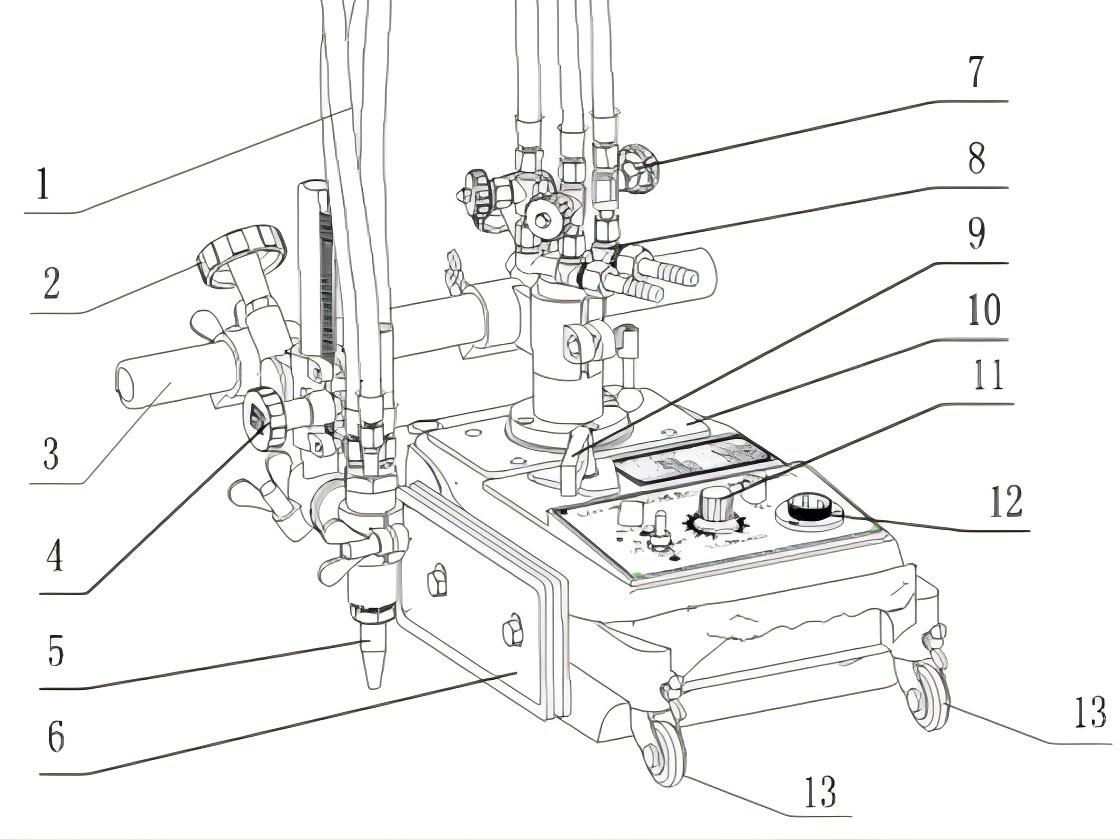

Description

1. Hose: The three hoses are used individually for fuel gas, preheating oxygen and cutting oxygen.

2. Cross hand wheel: To adjust the horizontal distance of torch

3. Cross gear rack

4. Vertical adjusting hand wheel of torch

5. Tip

6. Thermal baffle: To prevent the heat diffusing into the inner of machine.

7. Fuel gas two-port valve: To adjust gas-flow rate.

8. Gas distributor.

9. Clutch hand knob: "STOP" is parting. "START" is combination.

10. Body

11. Speed controller: Increase the speed from "0"to "10" Decease speed from "10" to "0" .

12. Outlet

13. Universal wheel

Technical Specification

| 1.Weight | 16 kg |

| Accessory | 7.8 kg |

| 2. Machine dimension | 435×210×240mm |

| 3. Speed control | silicon control |

| 4. Power source | AC 480V±10% 50HZ |

| 5. Cutting speed | 50~750/mm/min |

| 6. Cutting thickness | 5-100mm |

| 7.Groove angle | 0-45° |

| 8.Diameteral of cutting circle | ø200-ø2000mm |

| 9.Tip | G02(acetylene),G03(propane) |

| 10.Motor | DC 110V 50HZ 30W 4200r/min |

Contents of package

Carefully take the machine out of its case.

The contents of the standard package are shown below. Check them carefully before assembling the machine.

| 1. Body | 1set |

| 2.Torch unit assemblage | 1set |

| 3. Moving unit assemblage | 1set(including left-right, up-down moving unit assemblage and gear rack) |

| 4. Tip (acetylene) | 3pcs |

| 5.Power wire | 1pc |

| 6.Specification sheets and certificate of qualification | 1pc each |

| 7.Gas-in connector /pressure cat | 1set |

| 8.Ball-pane screw M4 | 2pcs |

| Standard accessory | |

| 1.Cutting circle unit assemblage | 1set |

| 2.convex guide rail | 2pcs(1.8m/pc)or grooved guide rail 1pc(1.8m) |